Features of Double-layer Machine

- Multipurpose production: The double-layer machine can satisfy the demands of various building projects by producing two distinct roof panel profiles, such as IBR roof panels and corrugated panels.

- Space optimization: The machine’s design maximizes the use of available space while minimizing production space requirements, condensing the equipment layout, and increasing production efficiency.

- Simple operation: The double-layer machine’s control system and operation interface are designed to be easily understood by users, which lowers operating complexity and increases production efficiency.

- Low maintenance expenses: To guarantee the stability and longevity of the equipment, lower the failure rate, and save maintenance costs, the machine employs premium materials and cutting-edge production technology. Additionally, we provide thorough after-sales care to guarantee that the machinery is constantly in top shape.

Machine parts

1) Double-layer roof panel machine with pre-cut knife

2) Double-layer roof panel machine roller

The roller is made of high-quality bearing steel GCr15, processed by CNC lathe, heat treated, and hard chrome plated on the surface.

With feed guide rail, the fuselage frame is welded with 300# H-shaped steel.

3) Double-layer roof panel machine rear cutter

Made of high-quality mold steel Cr12 after heat treatment

Hydraulic motor: 3.7KW, hydraulic pressure range: 0-16Mpa

4)PLC control system

Easy to operate

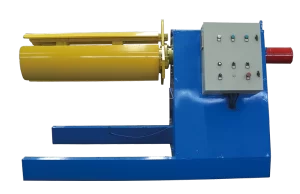

5) Double-layer roof panel machine unwinder

Manual unwinder: one set

No power, manually control the shrinkage and stop of the inner hole of the steel coil

Maximum feed width: 1250mm, steel coil ID range 480mm±30mm

Capacity: maximum 5 tons

5-ton hydraulic unwinder with car and without car are available

Application

- Residential buildings: Because of their low weight, great strength, robust resistance to earthquakes, quick production turnaround, and attractive look, corrugated metal roof panels are perfect for residential building roofs. Residential structures might have roof panels that are precisely and swiftly produced using double-layer machines.

- Commercial structures: Double-layer machines may also provide premium roof panel solutions for commercial buildings, including stores and restaurants. In addition to being elegant and long-lasting, corrugated roof panels may successfully defend commercial premises and provide a solid atmosphere for business operations.

- Public amenities: The roof panels made by double-layer machines might be crucial in projects involving public facilities, such as kiosks and restrooms. Since these buildings often need to be installed and dismantled rapidly, corrugated roof panels may provide a sturdy roof structure while satisfying this need.

- Industrial structures: Double-layer machineries are very often used in these types of buildings. Large structures like industrial plants and warehouses may have their roof needs satisfied by the corrugated roof panels they manufacture, which also offer the benefits of excellent load-bearing capability and corrosion resistance.

- Large-scale projects: Double-layer machines may also be advantageous in large-scale engineering projects like stadiums and airports. The double-layer machine’s accurate and efficient manufacturing allows it to produce a lot of high-quality roof panels for these projects, which guarantees their timely completion.