The main features of the tile roll forming machine are as follows:

- Production efficiency is greatly increased by the tile forming machine’s use of cutting-edge mechanical construction and transmission systems, which enable quick and continuous production. It is manageable to handle both small-scale customization and large-scale manufacturing.

- High adaptability: To fulfill the demands of various building and decorating projects, the machine can make tiles of various sizes, shapes, and textures. The tile forming machine is a popular piece of equipment on the market because of its versatility.

- Sturdy and trustworthy: The tile forming machine uses top-notch components and cutting-edge manufacturing techniques to guarantee the equipment’s reliability and longevity. It has a lengthy operating lifespan that lowers maintenance costs and the failure rate.

- Safety of operations: We took the operator’s safety into complete consideration throughout the design phase. The tile forming machine is outfitted with emergency stop buttons, safety protection mechanisms, and other safety features to guarantee that the machine can be promptly halted in case of an emergency, safeguarding the operator’s safety.

Machine Parts

Tile Forming Machine with Pre-Cutter:

Equipped with pre-cutters to ensure accurate cutting during tile forming and improve production efficiency.

Tile Forming Machine Roller:

The roller is made of high-quality bearing steel GCr15, which is precisely processed and heat-treated by CNC lathe, and the surface is hard chrome plated.

Equipped with feed guide rails, the fuselage frame is welded from 300# H-shaped steel to ensure overall stability and durability.

Tile Machine Rear Cutter:

The rear cutter is made of high-quality mold steel Cr12 after heat treatment to ensure long-lasting and sharp cutting effect.

Equipped with a 5.5KW hydraulic motor with a hydraulic pressure range of 0-16Mpa to ensure stable and efficient cutting process.

PLC Control System:

Adopting advanced PLC control system, it is easy to operate and can achieve precise control and automated production.

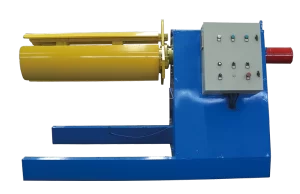

Double-layer roof panel machine unwinder:

Manual unwinder: Contains a set of manual unwinders, no power, manual control of steel coil inner hole shrinkage and stop.

Maximum feed width: 1250mm, coil ID range 480mm±30mm, maximum production capacity up to 5 tons.

Hydraulic decoiler: Optional 5-ton hydraulic decoiler, available with or without car configuration to meet different needs.

This tile forming machine ensures precision and efficiency in every step of the production process through precision design and the use of high-quality materials. Whether it is the pre-cutter, roller, post-cutter or control system, it reflects high-standard manufacturing technology and provides users with reliable and durable production equipment.