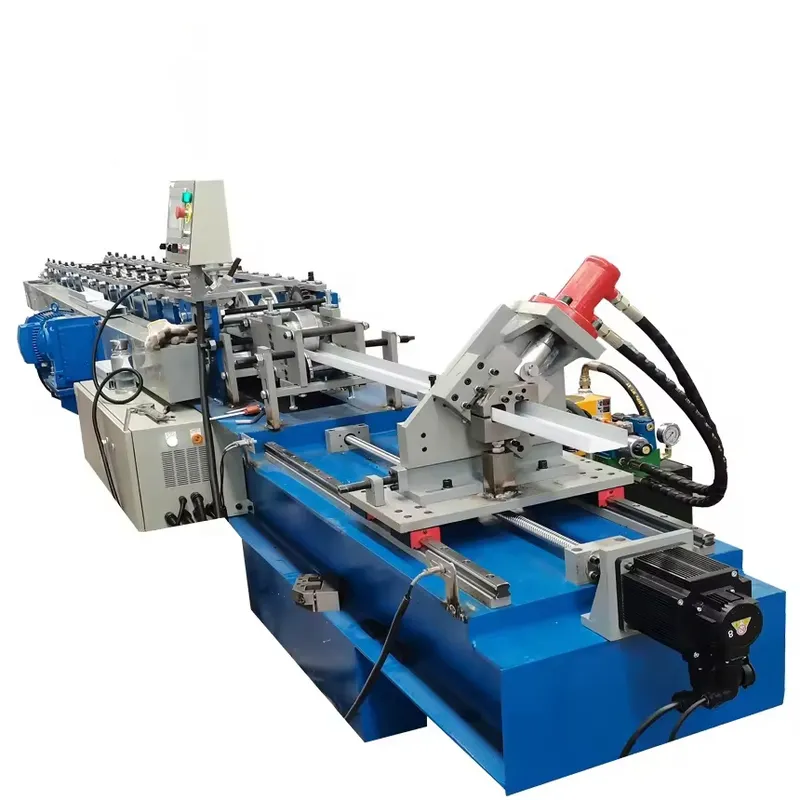

The column and track roll forming machine is a versatile production equipment that can efficiently produce C-shaped columns and U-shaped tracks in the same machine. These two materials play an important supporting and installation role in the construction industry. Through roll forming technology, the machine can accurately and quickly produce columns and tracks that meet standards, providing solid and reliable basic materials for construction projects.

Column track roll forming machine characteristics

- Production efficiency is greatly increased by the column track roll forming machine’s use of cutting-edge roll forming technology, which enables it to constantly and effectively make cold-bent steel products like columns and tracks.

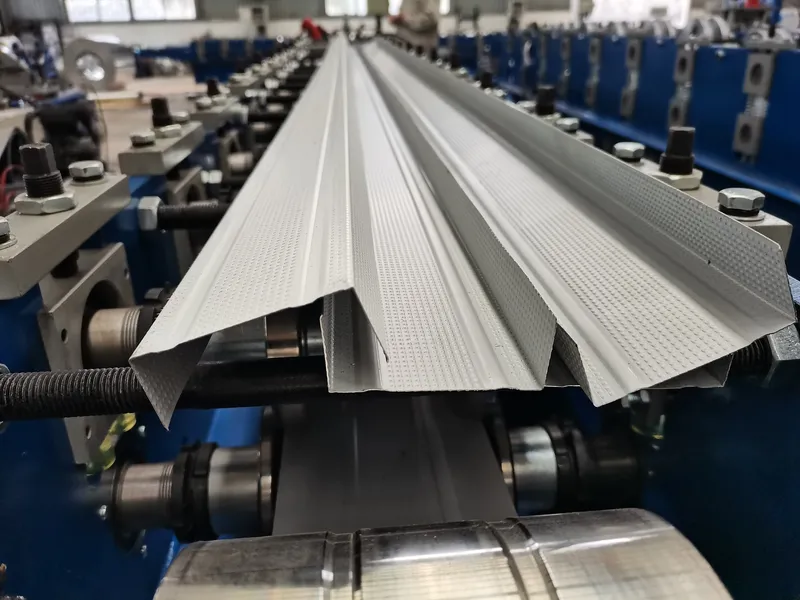

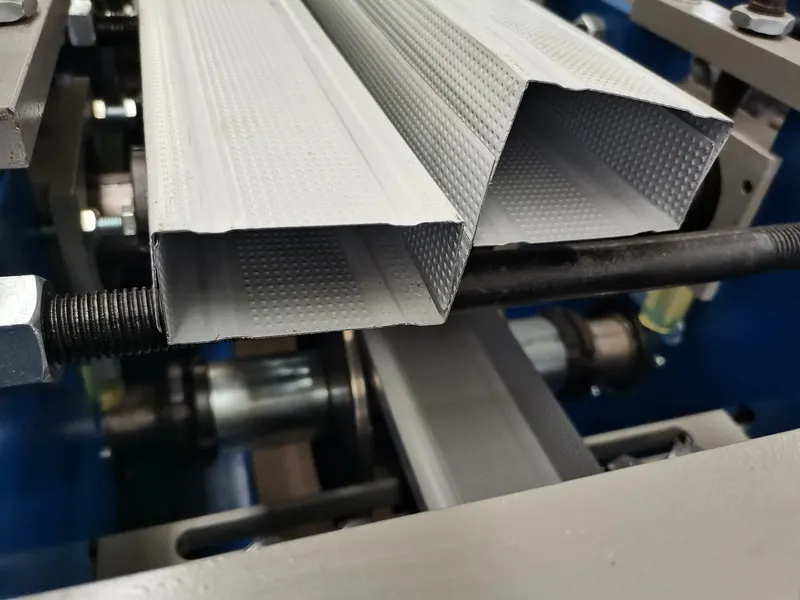

- Accurate forming: The apparatus has many rollers that are made to fit the product’s dimensions and form. The raw materials are continuously rolled, progressively deforming them until the end result has a precise and uniform shape.

- Strong flexibility: The equipment may be tailored to meet the demands of producing products with varying specifications, sizes, and forms by modifying parameters like roller spacing, speed, and pressure.

- High degree of automation: Precise control systems are often installed in the equipment to enable automated operation, minimize human interaction, and enhance production stability and product uniformity.

- Energy conservation and environmental protection: The column track roll forming machine satisfies the production criteria for energy conservation and environmental protection since it uses comparatively less energy during operation and minimizes raw material waste.

- Simple and intuitive equipment operating interface that is easy to learn and quickly get operators started means lower training expenses.

- Easy maintenance: The equipment’s modular component design and small construction make it simple to repair and replace, which lowers downtime and raises the equipment’s utilization rate.

- Strong durability: To guarantee that the machinery has strong durability and stability and can run steadily for a long period, the column track roll forming machine uses premium materials and manufacturing technology.

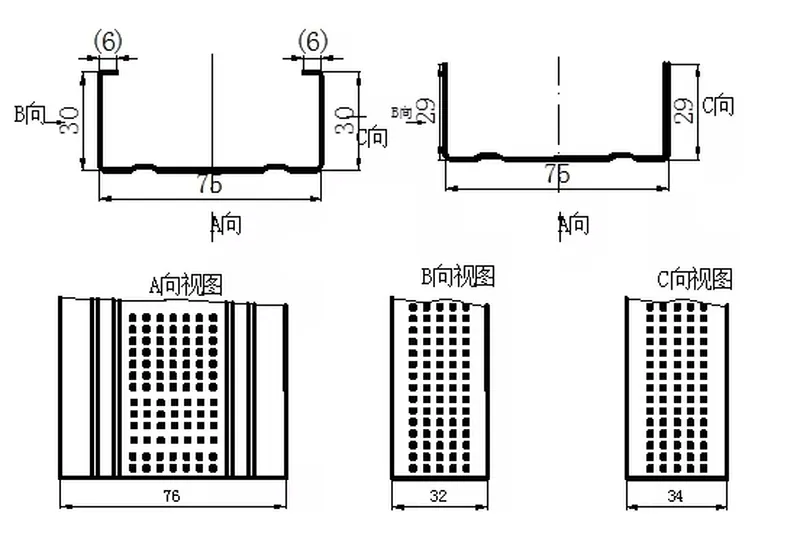

Profiles of stud and track machine

Introduction to the main components of the stud track machine:

Feeding system:

The feeding system is responsible for introducing the raw materials into the machine for subsequent processing. It usually includes one or more feed rollers to ensure that the material enters the forming area smoothly and continuously.

Machine roller:

The roller is one of the core components of the stud track machine and is responsible for pressing the raw materials into the predetermined shape. The roller is made of high-quality bearing steel GCr15 material, processed by CNC lathe and heat treated, and hard chrome plated on the surface to improve wear resistance and service life. These rollers are precisely designed and manufactured to ensure high precision and consistency of the product.

Non-stop forming tool:

The forming tool is a key component used for cutting and forming in the stud track machine. The non-stop forming tool design allows the machine to perform cutting and forming operations during continuous production without stopping and waiting, thereby greatly improving production efficiency.

PLC control system:

The stud track machine is equipped with a PLC control system to control various operations of the machine. The PLC control system is easy to operate and powerful. Users can easily set parameters, monitor operating status, and realize automated production through the control panel. The system provides two optional configurations to meet the needs of different users.

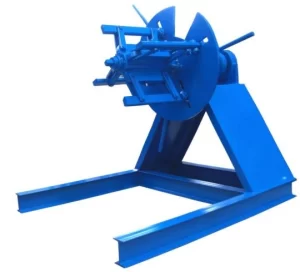

Uncoiler:

The uncoiler is responsible for unwinding the raw material coil and feeding it into the feeding system. The stud track machine provides two optional uncoiler configurations:

Manual uncoiler: suitable for small-scale production or occasions where manual operation is required. Users can control the unwinding speed and tension of the coil through manual operation.

Hydraulic uncoiler: suitable for large-scale, automated production needs. The hydraulic uncoiler adopts hydraulic drive, has a higher degree of automation and more stable unwinding performance, and can ensure the smooth unwinding and precise control of the coil.

Application of columns and track machines in the construction and decoration industry

Application of columns:

- Structural stability: The columns provide excellent structural stability with their unique structural design and material selection. In construction, columns bear the important task of supporting structural members such as roofs and floor slabs to ensure the overall safety of the building.

- Lightweight and high strength: Columns are usually made of lightweight materials, such as aluminum alloy, stainless steel, etc., which greatly reduce the deadweight of the columns while ensuring structural strength, thereby reducing the overall load of the building.

- Easy installation: The design of the columns enables them to be quickly cut and positioned, which is convenient for precise installation at the construction site. At the same time, the columns are usually equipped with standardized connectors such as screws or nails, making the installation process simpler and faster.

- Fast construction speed: Due to the easy installation of the columns, the construction speed can be greatly increased and the construction period can be shortened. This is especially important for projects that need to be completed quickly.

Application of tracks:

- Simplified installation process: The track system facilitates the installation of the ceiling. Through the track, the ceiling material can be easily hung above without complicated fixing work. This greatly simplifies the installation process and improves construction efficiency.

- Flexibility and adjustability: The track system allows the ceiling to be flexibly adjusted to suit different decorative needs and space layouts. By adjusting the position and angle of the track, the ceiling can be easily moved, rotated, and other movements can be achieved, providing more possibilities for interior decoration.

- Modern decoration style: The simple and beautiful design of the track system makes it an ideal choice for modern decoration styles. By matching it with other decorative materials, a stylish and modern interior environment can be created.

About Us

Our company is a leading enterprise focusing on the field of construction and manufacturing equipment, committed to providing customers with high-quality column and rail roll forming machines.

Our roll forming machines for columns and rails are a vital and essential piece of machinery used in the construction sector. The machine uses cutting-edge roll forming technology, which correctly and effectively transforms raw materials into columns and rails with a range of dimensions and forms. Our machine is capable of handling intricate curve designs as well as straightforward shapes with ease, guaranteeing the accuracy and quality of the final output.

In order to accommodate the demands of various clients, our column and rail roll forming machine also comes with a number of configurable configurations. We can provide an uncoiler that meets your production demands, whether it be a hydraulic or manual uncoiler. Furthermore, we provide individualized modification services to create the best machine configuration based on the unique requirements of our clients.

If you choose our roll forming machine for columns and rails, you will have manufacturing equipment that is accurate, dependable, and efficient. This will provide your building project a sturdy and dependable foundation material.