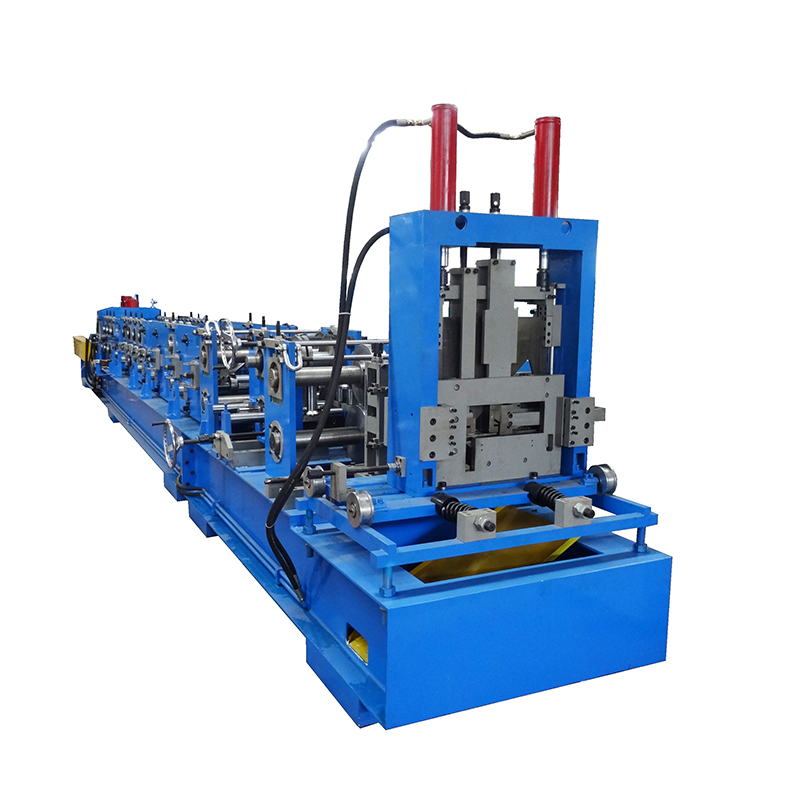

A specialized piece of machinery called a high-speed stud rolling forming machine is used to manufacture installation and support studs for the construction sector.

Advantage

- High speed: To satisfy the demands of the construction sector for speedy manufacturing, this kind of equipment often has an efficient production capacity and can roll-form studs fast.

- Precision forming: By using rolling technology, the apparatus can precisely regulate the size and shape of the studs to make sure they adhere to use guidelines and industry norms.

- High degree of automation: Most contemporary high-speed stud rolling forming machines are outfitted with cutting-edge control systems and automation tools, enabling automated loading, rolling, unloading, and other operations. This lowers the need for manual intervention, boosts output, and enhances product quality.

Stud Roll Forming Machine application:

- Building sector: The primary function of high-speed stud rolling forming machines is to manufacture installation and support studs needed by the construction sector, such as those used in scaffolding, steel constructions, formwork supports, and other applications.

- Other industries: This kind of equipment may be used in industries like machinery manufacture and the production of automobile components, among others, that need for precision stud formation, in addition to the construction sector.

Characteristics of the Stud Roll Forming Machine

Light steel keels may be produced using the column forming machine to suit a variety of requirements. It may be used to construct factories, light houses, villas, and other structures as part of the building structure. Because of its strong strength and low weight, the building structure is more earthquake-resistant and solid. Its quick construction also helps to significantly reduce the time needed for construction. Furthermore, light steel keels may be coupled with other construction materials, including concrete and brick walls, to create a composite structure that will increase its total wind resistance and bearing capacity.

The column forming machine’s light steel columns are crucial for external wall ornamentation. They may be installed with curtain walls, stone veneers, outside wall insulation systems, and other materials. They can also serve as the supporting framework for exterior wall decorative materials. The light steel keel’s strength and low weight may lessen the strain on the building’s structural integrity while strengthening and enhancing the outside wall décor. Simultaneously, its high malleability and versatility allow it to meet a wide range of modeling specifications and architectural aesthetics, enhancing the building’s expressiveness and originality.

Profiles and flow chart of track roll forming machine

Main reasons for choosing a high-speed stud roll forming machine

- High-efficiency production: By producing a large number of studs quickly, the high-speed stud roll forming machine greatly increases production efficiency. Time is money when it comes to building projects, and a quick production cycle may guarantee on-time completion while lowering escalating expenses brought on by delays.

- Lower labor costs: Cutting, shaping, grinding, and other manual activities are all part of the labor-intensive conventional stud manufacturing technique. These procedures may be automated by the high-speed stud roll forming machine, which lowers the need for personnel and labor expenses. Furthermore, machine operation reduces waste and human mistake since it is more precise and efficient than manual operation.

- Guarantee product quality and uniformity: The high-speed stud roll forming machine precisely controls the studs’ size, shape, and surface quality using cutting-edge rolling technology. The machine can manufacture studs that satisfy a range of standards and specifications by adjusting certain parameters, guaranteeing product dependability and uniformity. This is important for construction projects since the building’s overall stability and safety are directly impacted by the precision and steadiness of the columns and rails.

- Strong adaptability: The high-speed stud roll forming machine can change to meet the demands of producing studs with various models and specifications. The machine may effortlessly convert to create studs of various sizes and shapes by modifying the mold or the settings, satisfying the various demands of building projects. The machine is more useful and effective because of its versatility.

- Energy conservation and preservation of the environment: The high-speed stud roll forming machine uses less energy and produces less trash than previous manufacturing techniques. The machine may lessen its environmental effect by streamlining the manufacturing process and cutting down on wasteful material use, aligning with the green development trend of the contemporary building sector.

- Simple maintenance and upkeep: The high-speed stud roll forming machine often has a modular construction, which facilitates easier, faster maintenance. In addition, the machine has high endurance and stability, allowing it to function steadily for a long period without needing regular maintenance or component replacements. This raises the equipment’s economic advantages and usage rate while lowering maintenance and time expenses.

Component of stud and track machine

Feeding system:

Introduce raw materials into the machine smoothly and continuously for processing.

Roller:

Core component, made of high-quality bearing steel GCr15, with hard chrome plating on the surface to ensure wear resistance and high precision.

Forming tool:

Cutting and forming in the continuous production process without stopping, improving production efficiency.

PLC control system:

Easy to operate, powerful functions, realize automated production, and there are two configurations to choose from.

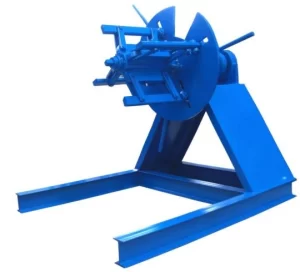

Unwinder:

Manual unwinder: suitable for small-scale or manual operation.

Hydraulic unwinder: suitable for large-scale, automated production, stable and precise.