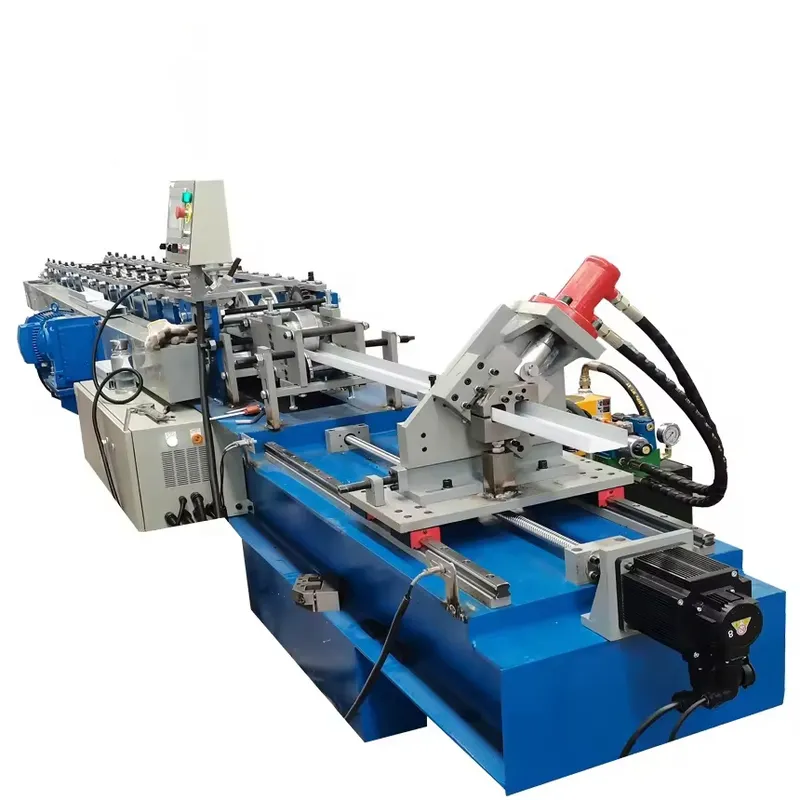

The automatic changeover CZ purlin forming machine is a productive and adaptable piece of machinery that can produce C- and Z-type purlins of Taiwanese quality to satisfy the demands of various clients.

Equipment features:

- Automatic changeover: The machine is equipped with an automatic changeover feature, thus adjusting the mold or setting settings by hand is not necessary. To create purlins with a variety of qualities and standards, the machinery has the ability to recognize and automatically transition between several production modes.

- Production efficiency is substantially increased by the equipment’s use of cutting-edge production technology and control systems, which enable an effective and continuous manufacturing process.

- High precision: The manufacturing of purlins with precise dimensions and consistent quality is guaranteed by the equipment’s high-precision control system and mold design.

- Versatility: It can be used to produce C-type and Z-type purlins with a range of profiles to satisfy diverse engineering and construction requirements.

Features of CZ integrated purlin machine:

- Simple to use: The CZ integrated purlin machine increases production efficiency and is simple to use.

- Quality of the product: The produced steel purlins in the C and Z shapes are characterized by their high compressive strength, customizable specifications, and homogeneous wall thickness.

- Financial effectiveness: Steel purlins in the C and Z shapes are inexpensive, lightweight, and simple to assemble. From the processing facility, they can be cut to length and sent straight to the construction site.

- Safety: A safety alarm system is built into the apparatus. To increase process safety, the device will immediately sound an alarm once an accident happens.

- Regulating precision: The equipment’s drive system uses variable frequency control, which makes it possible to more precisely identify the goods on the manufacturing line, regulate production speed and purlin parameters, and satisfy various accuracy requirements.

Machine Parts

1. Leveling and Feeding Instrument

Tie rod: ҄20; Side wall thickness: Q235 t25mm

Shafts made of 45# steel with a diameter of 115mm and a strong chrome tone plating coated and expertly machined

2. Hydraulic Punching and Pre-Cutting Instrument

The hydraulic system is shared by the pre-punching and pre-cutting devices.

7.5 kW hydraulic motor and 16 MPa hydraulic pressure

Three-cylinder hole punching system for punching holes in web and flange made of mold steel Cr12MoV is the material of the punching and cutting tool.

3. Main apparatus

Shafts Diameter: about 95, well machined Gear/Sprocket driving

Servo motor primary: 30 kW

Redcucer motor speed: K series;

Six pieces of size-changing motors that are computer-controlled automatically

Block sliding: 150 * 150 mm

4. Hydraulic Cutting Tool After

To clip, post and pause

Every form size could be cut using a single cutter.

5. PLC Computer Control System Control Voltage: 24V Cut-to-Length Tolerance≤±1 mm

Application scenarios of CZ purlin machine

- Industrial plant: Fixings between vertical columns or top keels and roof panels: In industrial facilities, CZ purlin machine-produced C and Z-shaped steel purlins are frequently utilized as transverse members to join and fasten roof panels, top keels, or vertical columns. This kind of purlin can satisfy the load-bearing and stability needs of various industrial facilities due to its uniform wall thickness, customizable specifications, and high compressive strength.

- Large and medium-sized industrial and civil buildings’ primary force-bearing structure: The waste that the C/Z steel machine rolls out is straight and performs well in terms of tensile, bending, and compression. Large and medium-sized industrial and civil buildings (such hangars, engine depots, factories, and warehouses) can use this product as their primary force-bearing structure to support and carry a variety of loads.

- Commercial buildings: CZ purlin machines’ steel purlins, which are made in the form of C and Z connections and fixations between floor slabs and bridges, can be used to improve the stability and bearing capacity of the building’s structure.

- Support of canopy: To guarantee the stability and safety of canopies, commercial structures can also utilize C and Z steel purlins to support canopies.

- Public buildings: Supporting suspended ceilings or lighting: To improve the overall stability of the building, C and Z steel purlins made by CZ purlin machines are frequently utilized to support suspended ceilings or lighting in theaters, exhibition halls, stadiums, and other public buildings.

- Market flower shed roof load bearing and wall support: CZ purlin machines’ products can supply dependable roof load bearing and wall support for structures like these, ensuring the building’s stability and safety.

Contemporary building facilities in rural townships:

Grape rack columns, vegetable greenhouse columns, etc.: In order to improve productivity and the quality of buildings, prestressed concrete column forming machines, which include purlin machines, are widely utilized to produce cement products for use in contemporary rural township construction projects like grape rack columns and vegetable greenhouse columns.