With its efficient and exact production capacity, the floor deck forming machine has revolutionized floor deck manufacture in the current construction sector. This device is meant to shape and cut floor decks. It boosts manufacturing efficiency and cuts labor expenses, making floor deck manufacture more cost-effective.

Floor decks, an essential construction element, impact building stability and longevity. The construction industry needs high-quality panels, and the floor deck forming machine satisfies that need with its sophisticated technology and consistent performance.

The floor deck forming machine showed its automated manufacturing capability. It autonomously forms and cuts floor decks using precise control systems and efficient forming technologies, enhancing production speed and quality. The equipment’s operation is straightforward and easy to grasp, reducing operator skill requirements and manufacturing costs.

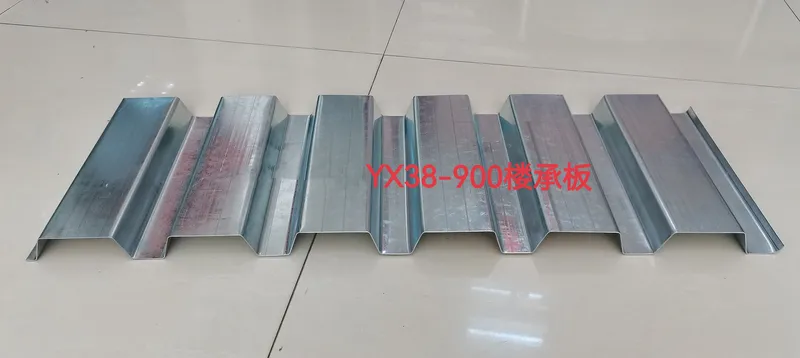

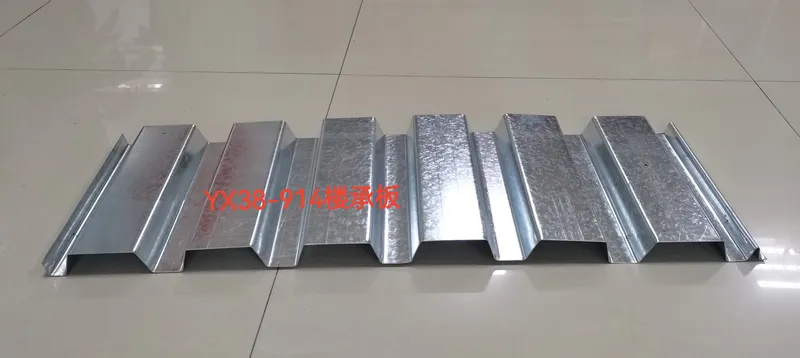

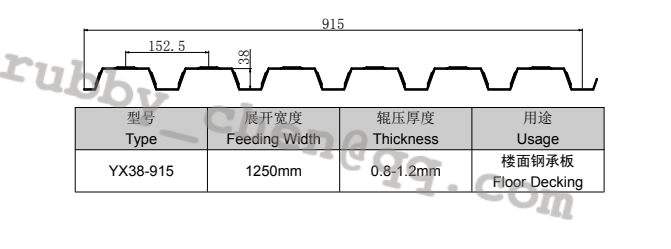

Profiles of Floor decking machine

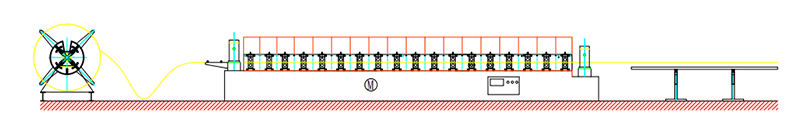

Work Flow

- The uncoiler is the beginning point of the floor deck making machine. To preparation for processing, the uncoiler progressively unwinds the coil (the floor deck’s raw material).

Uncoilers have tension management systems to keep the coil tensioned during unwinding, maintaining product quality. - The coil will enter the feed guidance device after being unwound by the uncoiler. Its major job is to smoothly and properly transfer the unwound coil to the next procedure.

- Through accurate guide wheels and guide plates, the feed guide device keeps the coil on the set route during transmission and stabilizes feeding speed.

- Optional pre-cutting device:The pre-cutting equipment is optional on the floor deck forming machine. Here, floor decks may be pre-cut to a certain length.

- To prepare materials for shaping, the pre-cutting apparatus precisely cuts the coil to the predetermined length.

- The roll forming system is the basic component of the floor deck forming machine. The roll forming system receives material from the feed guide and pre-cutting equipment.

- The roll forming mechanism pushes and shapes the material using properly engineered rollers to create the floor deck shape.

- Due to its precision and stability, the technology produces floor decks with great dimensional accuracy and surface quality.

- The hydraulic post-cutting device will receive the floor deck created by the roll forming system. This gadget cuts the floor deck precisely to meet requirements.

- The hydraulic post-cutting device uses modern technology and accurate cutting mechanisms to reduce material waste and assure precision and stability. The next phase is the export rack. The hydraulic post-

- cutting mechanism will carry the floor deck to the export rack for packing, shipment, and other activities.

- The export rack normally has anti-slip and anti-dumping characteristics to protect the floor deck during storage and transit.

The floor deck forming machine uses automated control and accurate mechanical action to quickly and efficiently turn raw materials into finished products. This boosts manufacturing productivity, lowers labor costs, and assures product quality.

Floor Decking Machine Functions and Features

Floor Decking Machine is a cold-rolled steel structural building material used to support floor concrete in construction. We produce and export standard and non-standard metal deck forming machines with the following key features:

- Effective forming: Floor Decking Machine forms metal decks fast and correctly to satisfy requirements and norms.

- Strong adaptability: Our forming machine can create conventional metal deck requirements and tailor non-standard specifications for customized applications.

- Automation: The equipment has an innovative control system that automates operation, simplifies manual operation, and boosts productivity.

- Accept OEM/ODM: We provide OEM and ODM services and may modify goods to match clients’ demands.

- High efficiency: Our Floor Decking Machine can produce up to 20 meters/minute, shortening the manufacturing cycle and improving market competitiveness.

- Humanized design, simple operating interface, and rapid start make the equipment easy to run and maintain. Equipment maintenance is also easy, lowering costs.

- Renewable and recyclable metal decking save energy and the environment. Using our molding equipment to make metal decks reduces construction waste, which supports green building and sustainable growth. Our equipment also addresses environmental considerations during design and production and reduces energy use and emissions.

- High precision: The machine uses high-precision molding technology and control system to increase product quality by ensuring metal deck dimensional correctness and surface quality.

- Strong stability: Our Floor Decking Machine meets applicable norms and specifications in design and manufacture, ensuring stability and dependability during long-term high-load operations.

Components of the machine

1. Feeding

2. Hydraulic pre-cutter

3. Rollers of floor decking machine

Rollers are made of high-quality bearing steel GCr15, CNC lathed, heat-treated, and available with hard chrome coating.

With feeding material guide, body frame manufactured of 300# H type steel by welding

4. Floor decking machine forming cutter

Made by high quality mold steel Cr12 with heat treatment

5. PLC Control system

Easy to operate

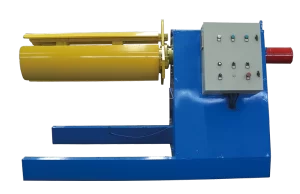

6. Decoiler

Manual Decoiler: one set

Un-powered,manually control steel coil inner bore shrinkage and stop

Max. feeding width: 1250mm, coil ID range 480mm±30mm

Capacity: Max. 5 Ton

With 5 tons hydraulic decoiler with car and without car for option

Choose us for floor decking forming machine manufacturing.

We have a strong technical team and years of expertise making floor decking forming equipment. Due to our market knowledge, continual R&D, and innovation, we provide efficient and reliable forming machine solutions.

- Quality and reliability: We oversee material selection and manufacturing to guarantee each shaping equipment meets high quality requirements. To guarantee long-term high-load performance, our equipment has been carefully tested.

- Our OEM/ODM service can tailor floor decking forming machines to your demands. We can satisfy your standard or non-standard standards and assure project success.

- Our floor decking forming machine can produce up to 20 meters/minute, shortening the manufacturing cycle and improving your market competitiveness.

- Convenient operation and maintenance: We prioritize user experience, so the equipment operating interface is straightforward and easy to grasp. Equipment maintenance is also easy, lowering expenses.

- Environment and sustainability: We practice green manufacturing. Our floor decking forming machines are eco-friendly and eliminate construction waste, supporting green building and sustainable growth.

- Our after-sales service includes equipment installation, commissioning, training, and post-maintenance. Our skilled staff will accompany you throughout the process to guarantee your equipment usage is worry-free.