Product

The insulating sandwich panel machine is an efficient production equipment specially designed for the uninterrupted manufacture of high-quality high-voltage sandwich panels. This sandwich panel is widely favored by the industry for its excellent insulation performance and durability, and is widely used in many fields such as construction, refrigeration, industrial equipment, etc.

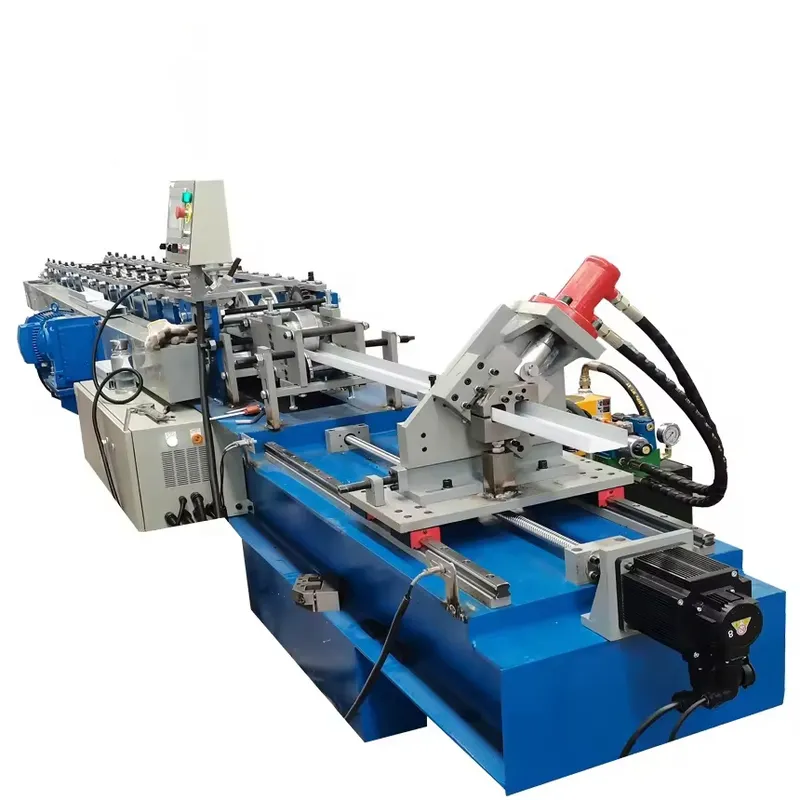

U Profile Roll Forming Machine parameters

- Suitable for materials with a thickness of 1.2-2.5mm

- The shaft is made of 45# and is precision machined

- Motor driven, gear chain driven, 16 rollers for forming.

- Frequency conversion speed regulation. Forming speed is about 18m/min

- PLC control system (touch screen brand: German Schneider Electric/Taiwan WEINVIEW,

- Inverter brand: Taiwan DELTA, encoder brand: Japan Koyo/Omron)

- Just adjust the required WEB, HEIGHT and LIP with the help of the position clock on it (with digital display, easy to operate) with the hand wheel,

- Then enter the required production data on the touch screen.

- All operations can be completed in just 5-10 minutes. No need to change rollers, gaskets or cutters like traditional old-fashioned machines (each change of production size takes more than 45 minutes).

- Combined with: PLC, inverter, touch screen, encoder, etc.

- Cutting length tolerance ≤±2 mm

- Control voltage 24V

- English user manual

Component of stud and track machine

Feeding system:

Introduce raw materials into the machine smoothly and continuously for processing.

Roller:

Core component, made of high-quality bearing steel GCr15, with hard chrome plating on the surface to ensure wear resistance and high precision.

Forming tool:

Cutting and forming in the continuous production process without stopping, improving production efficiency.

PLC control system:

Easy to operate, powerful functions, realize automated production, and there are two configurations to choose from.

Unwinder:

Manual unwinder: suitable for small-scale or manual operation.

Hydraulic unwinder: suitable for large-scale, automated production, stable and precise.

The column and track roll forming machine is a versatile production equipment that can efficiently produce C-shaped columns and U-shaped tracks in the same machine. These two materials play an important supporting and installation role in the construction industry. Through roll forming technology, the machine can accurately and quickly produce columns and tracks that meet standards, providing solid and reliable basic materials for construction projects.

High Speed Track Machine are excellent manufacturing tools in the construction sector. They can swiftly and precisely create robust and long-lasting trusses because to their exact and efficient technology. These trusses are essential to building undertakings. They ensure the safety and stability of buildings by providing dependable and sturdy support and installation frameworks. Large commercial buildings, tall skyscrapers, and intricate industrial facilities are all inextricably linked to the trusses made by these effective machines.

Standing seam roofing machines are state-of-the-art metal roofing processing tools that can create metal roof panels with special fastener hidden or concealed fastening systems and self-locking mechanisms. The stability of the roof panels is guaranteed by this cutting-edge technology, which also significantly enhances their endurance and attractiveness.