Experts in the field commend the C Purlin machine for its versatility and efficiency. This equipment reduces costs while increasing the precision, efficiency, and quality of building products. The expansion of the construction industry depends on these advantages.

Purlin machine customization is quite flexible. Each product may be precisely altered to customer requirements or sizes to ensure it satisfies design standards. To further automate and simplify production and ensure consistent and dependable output, the purlin machine is easily integrated into the present production line and works well with other construction equipment.

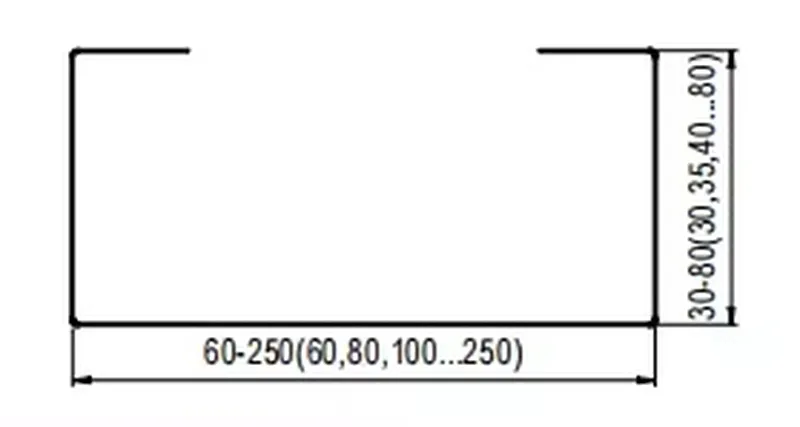

Profile and Specification

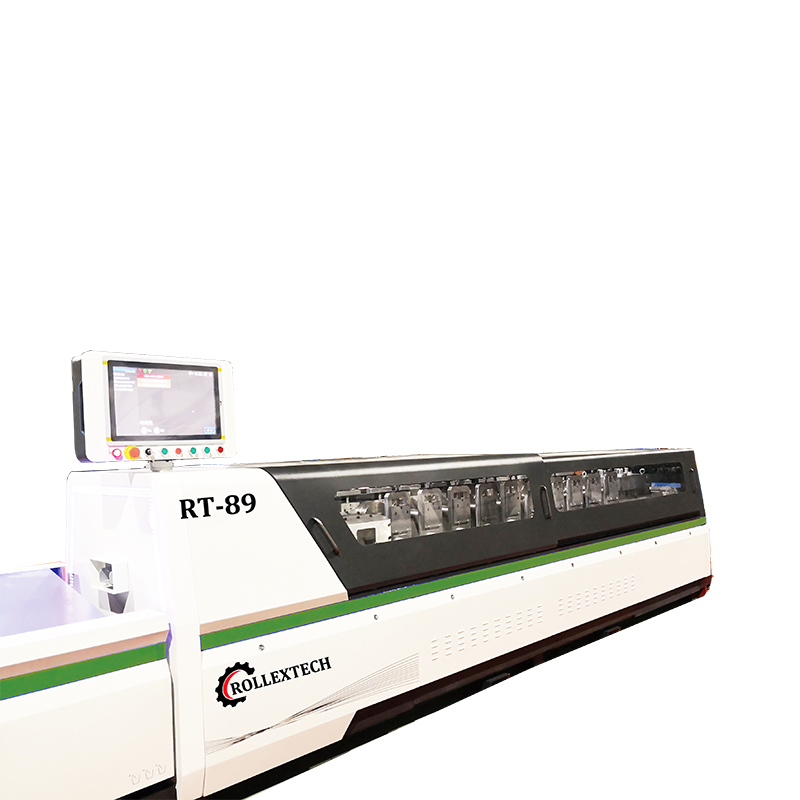

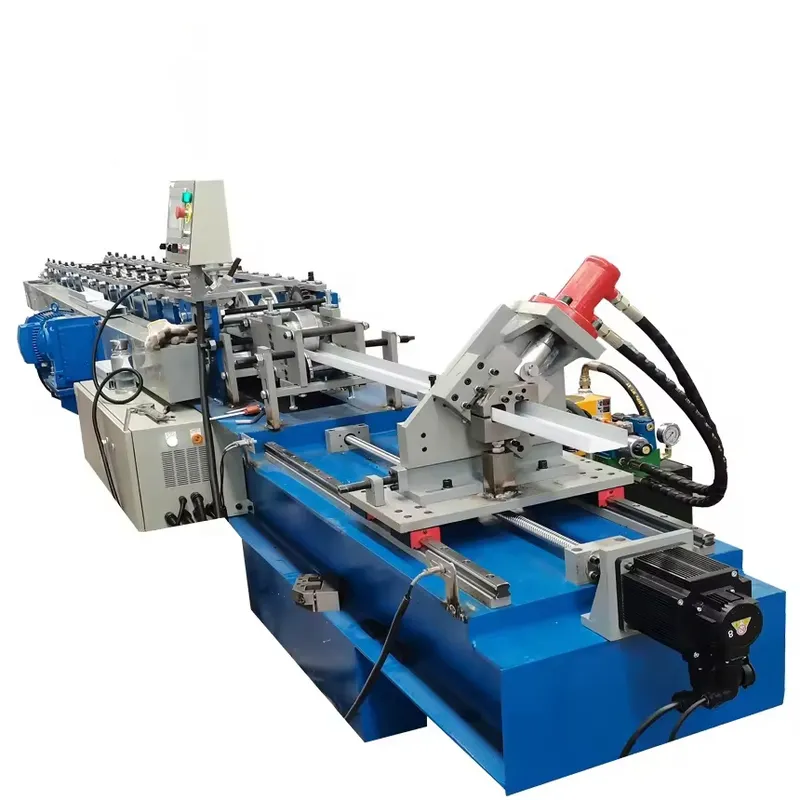

A decoiler, feeding and leveling apparatus, punching system, pre-shear, conveyor system, roll forming system, hydraulic post cutting, run-out table, hydraulic station, and PLC control system make up the C60-250 purlin machine. Its unique quick-change feature is that it comes with a liner guide that makes it simple and seamless for the machine to change the web. Produce standard goods that are suitable for current manufacturing, have a lengthy production line, no open mouth on final products, and can be changed in size in only one to three minutes. These features reduce labor costs and save time. The yield strength of the products may reach 235 MPa. This machine operates with exceptional accuracy and is easy to use.

Main features

The efficient and intelligent fully automated C-shaped purlin machine is mainly used to produce C-shaped steel structural purlins in a variety of requirements. It uses cutting-edge machining technology to transform steel plates into purlins of varied sizes, satisfying the demands of diverse industrial and construction sectors.

The C purlin machine, which is totally automated, has several benefits. First of all, it produces in an automated and efficient manner, greatly increasing productivity and cutting expenses. Second, the machinery complies with different technical and construction requirements by using precision machining to guarantee product quality and accuracy. In addition, the completely automated C purlin machine reduces noise and pollution and uses less energy, all of which are in line with the needs of contemporary industrial growth.

Components of the C purlin machine

1. C purlin machine feeding and leveling

It is used to flatten the material before feeding it into a roll forming machine.

2. Pre-punching device

Punch on a flat sheet. PLC controls punch quantity and horizontal position; vertical position is adjusted manually.

Punching quantity& size: as per customer’s requirement.

3. Pre-cutting device

It was used to trim raw materials before rolling them.

4. All purpose forming cutter(Optional)

5. C Purlin Main Machine

Choice of our business benefits

Our company produces a very effective C-shaped steel purlin machine. With precise machining, it quickly transforms steel plates into different-sized purlins. Fully automated fixed-length cutting and punching technology reduces labor costs and increases production efficiency.

- Energy efficiency and environmental protection: The noiseless and pollution-free output of the C-shaped steel purlin machine complies with modern environmental protection regulations. Construction becomes greener and uses less energy when manufacturing is efficient.

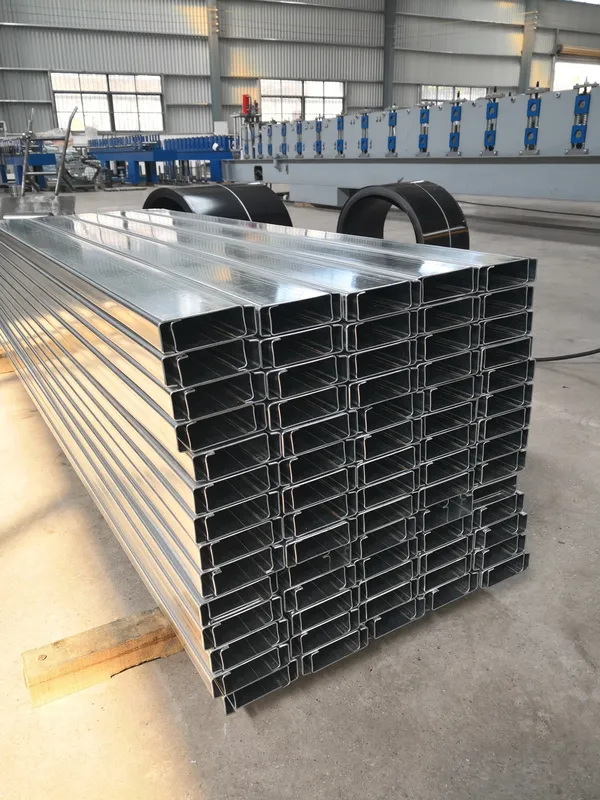

- Quality of the product: Our C-shaped steel purlin machine is constructed with premium bearing steel (GR15), 310H steel, and other components for stability and longevity. The device employs secondary molding to ensure squareness and proper angles. You may alter the top size. You may vary the rolled material thickness from 1.5mm to 3mm to ensure product diversity and usefulness.

- Intelligent and automated: The cutting-edge computer control system on our C-shaped steel purlin machine automates every step of the operation, enhancing output and ensuring product excellence. Costs are reduced by the device’s ease of use and maintenance.

- Tailored service: Our company can adapt C-shaped steel purlin machine solutions to meet specific production needs of customers. In order to assist customers promptly and efficiently, we provide knowledgeable technical assistance as well as after-sales care.

- C-shaped steel purlins are used in bridges, roadways, high-rise buildings, and other constructions. In addition to producing high-quality purlin products, our C-shaped steel purlin machine offers engineering project assistance and solutions.

FAQ:

What is a Purlin machine?

Purlins are made using mechanical purlin machines. Different sized C- and Z-type purlins are produced using purlin machines. This equipment is utilized to create purlins for vegetable greenhouse columns, grapevine stand columns, orchard columns, animal farms, flower planting shed columns, and other locations in modernized rural township construction facilities. Purlin machines are easy to use and maintain, and they are ten to fifteen times more efficient than handicrafts.

What does C Purlin become used for?

C purlins are used in building roof and wall structures to support roof and wall panels. The building and gravity load are supported by its “C” cross-section, strength, and stiffness of the hot rolled steel strip. C purlins are seismically efficient, easy to install, and may be bolted or welded to the building structure.

Which purlin is stronger, Z or C?

Which is stronger, Z or C purlin, based on needs and use environment? Every purlin type has advantages and is often used. Z purlin is robust and easy to install, whereas c purlin is robust and stiff. Thus, the situation has to be considered while choosing a purlin type.

What distinguishes C channels from C purlins?

Use and shape of C channel and C purlin are different.C purlin is used in semi-circular or C-shaped roof and wall constructions, whereas C channel is employed in general construction and traditional waist-shaped buildings. The material and specifications for C channels and C purlins vary depending on the purpose and requirements.

What distinguishes the mc channel from the c channel?

The cross-sectional shape and application range of MC and C channels differ primarily. While C channel has a waist-shaped cross-section for ordinary construction and historic structures, MC channel has an irregular trapezoidal cross-section for large spans and load-bearing capacity. In addition, the material and specifications for MC and C channel steel may differ.