As a highly respected mechanical tool in the construction industry, the importance of the purlin machine is self-evident. It not only shows great potential in improving production efficiency and reducing production costs, but also plays a key role in improving product quality and processing accuracy. These advantages are of immeasurable value to the sustainable and healthy development of the construction industry.

Another highlight of the purlin machine is its high degree of customizability. Regardless of the manufacturing requirements of any specifications and sizes, the purlin machine can accurately meet the personalized requirements of customers by flexibly adjusting parameter settings. This flexibility not only broadens the application range of the purlin machine, but also makes it an indispensable and important tool in the construction industry.

More advanced is that the purlin machine can be seamlessly connected with other construction machinery to jointly build an efficient and comprehensive production line. On this production line, each process is closely connected, and automation and continuous manufacturing are perfectly realized, which further improves production efficiency and reduces labor costs, while also ensuring the stability and consistency of product quality.

Our advantages

- We as a manufacturer are Specialized in all kinds of cold roll forming machine since 2010.So for the design and produce there are much experience and professional people.

- Customized design, color and logo are also accepted! Our specialized experts and skilled workers keep devoting their hard working to ensure the machine with high quality.

- Schneider PLC system:Ensuring high accuracy and easy to operate!Full Automatic: Just input length of the sheets and numbers of the piece you need, then the machine will start to work as your order.

- Our machines exported to the Southeast Asia, Middle East, Africa, North & South America more than twenty countries and regions.We have professional team, complete production system, high quality products, good service.

- Within the ONE-YEAR period, we could supply you the replacement parts free of charge for any damaged parts caused by quality problems.

Main Technical Data: |

|

| Size | C60-250 |

| Dimension | 7800*1600*1600mm |

| Hydraulic Motor Power | 15KW |

| Motor Power for adjusting C size | 0.37kw*2+0.75kw |

| Motor Power for guiding | 0.18kw*2 |

| Motor Power for adjusting punching hole | 0.18kw*2 |

| Forming Speed | 0-30m/min |

| Voltage | 380V/50HZ/3PH |

| Effective Width | 60-250mm |

| Material Width | 122-402mm |

| Flange Height of Purlin | 30-80mm |

| Material Thickness | 0.8-2.2mm |

| Control System | PLC Computer Control |

| Material for All Roller | 45# Steel Chrome-faced |

| Material for Shaft | 40Cr steel |

| Material for cutter | Cr12Mov |

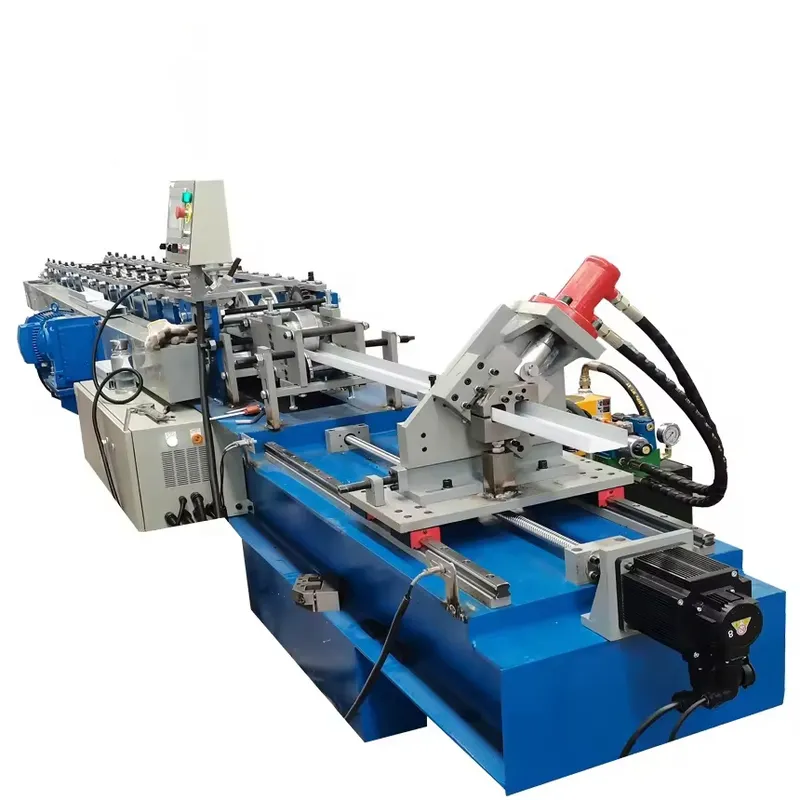

Components of the C Purlin Roll Forming Machine

C purlin machine feed material leveling

Function: Leveling the material before feeding it into the roll forming machine to ensure uniform flatness and correct shape of the material when it enters the machine.

Features: The machine may be equipped with an automatic adjusting device that can adaptively adjust to the characteristics and thickness of different materials to achieve the best leveling effect.

Pre-punching device

FUNCTION: Performs punching operations on the flat sheet according to preset specifications and positions.

Control mode:

PLC controls the number of punching holes and horizontal position to ensure the accuracy and consistency of punching position.

Vertical position is manually adjusted to suit different punching needs and material thickness.

Punching Parameters:

The number and size of punched holes can be customized according to specific customer requirements.

The range of hole diameters may cover from 0.5 mm to 15 mm and the hole spacing can be adjusted from 1 mm to 50 mm.

Pre-cutting device

Function: Preliminary trimming and cutting of raw material prior to rolling for subsequent processing and molding.

Features: With possible automated operation, this device can quickly and accurately complete the pre-cutting of raw materials, improving productivity and processing quality.

Universal molding cutter (optional)

Function: It is used for further cutting and trimming of already formed C purlins to meet different lengths and shapes.

Features:

High versatility, can adapt to many different sizes and shapes of C purlin cutting needs.

It may be equipped with high-precision cutting system and safety protection device to ensure cutting precision and operation safety.

C purlin main machine

C purlin main machine is the core equipment in the C purlin machine production line, featuring high precision molding, high productivity, adjustability and stability. By cooperating with other auxiliary equipments, it can efficiently and stably produce C purlin products that meet customers’ demands.

Certificate