Benefits of a C Roll Forming Machine

- High production efficiency: To satisfy client demands, the C-shaped steel forming machine can swiftly make C-shaped steels of different specifications.

- High level of automation The majority of contemporary C-shaped steel forming machines include automated control systems that allow for unattended operation, significantly increasing production efficiency.

- High precision: The C-shaped steel forming machine can guarantee the product’s correctness and uniformity throughout the manufacturing process, enhancing the product’s quality and stability.

- Broad range of applications: The C-shaped steel forming machine can create C-shaped steels with a variety of standards that are appropriate for a number of industries, including railroads, cars, and construction.

Utilizing C-shaped steel

C-shaped steel is a crucial material for walls and roof construction. Among its primary duties are:

- Maintaining the structural integrity of buildings: C-shaped steel has exceptional strength and stability, making it suitable for bearing the weight of wall panels or roofs.

- As the primary structure that bears weight: The primary load-bearing structure of large and medium-sized industrial and civil buildings, such as factories, warehouses, engine depots, hangars, exhibition halls, theaters, stadiums, and market flower sheds, can be made of C-shaped steel finished products because of their good tension, bending, compression, and straightness. wall flat support and roof load carrying.

- Customized processing: The C-shaped steel forming machine is capable of producing C-shaped steel in a variety of sizes and forms to satisfy a range of unique requirements. It also enables customized processing.

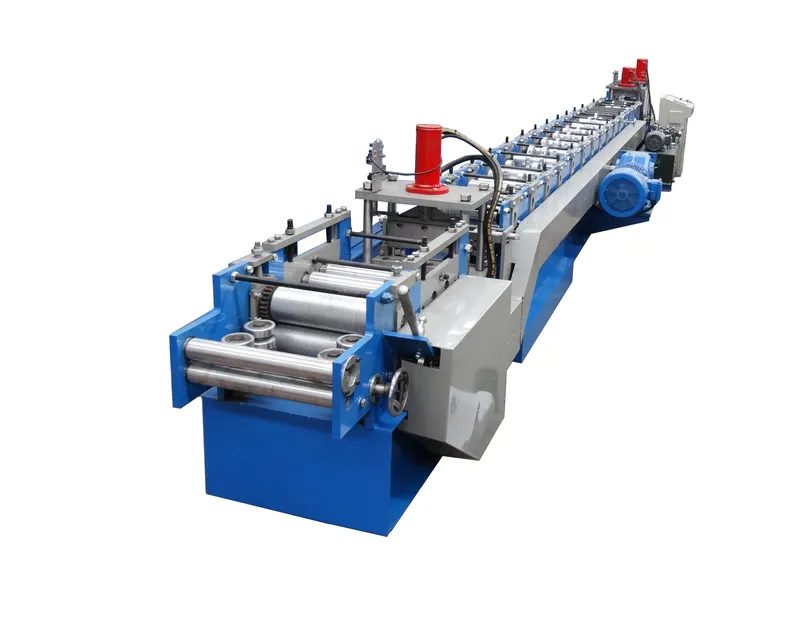

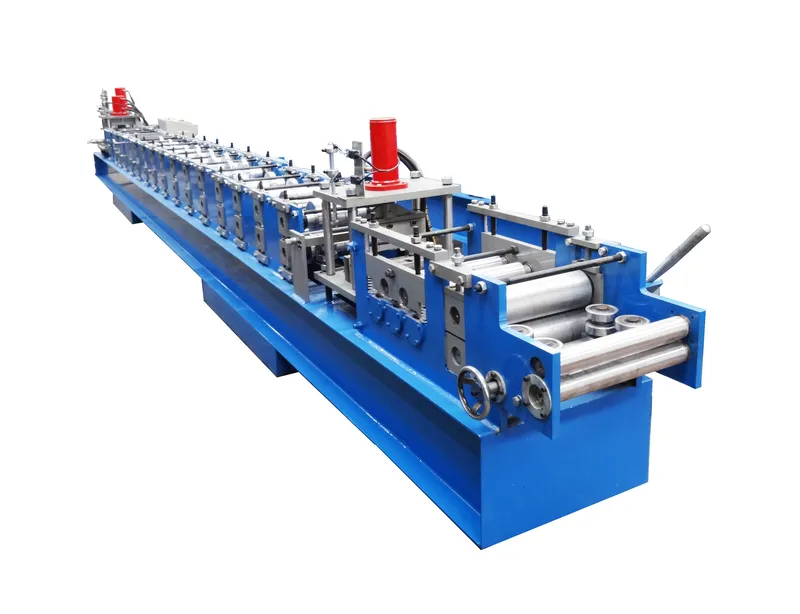

What is a roll forming machine with an a C roll forming machine?

C steel channel is continuously produced by a C roll forming machine using cold-rolled or galvanized steel strips after they are fed, punched for holes, bent, and cut.

With a user-friendly HMl panel, this machine is fully automatic and simple to operate. It is made up of a single decoiler, roll forming machinery, roll guiding apparatus, hydraulic cutting, PLC control system, and collection table.

Their key benefits include exquisitely personalized designs, simple, stable operation, and a robust body structure.

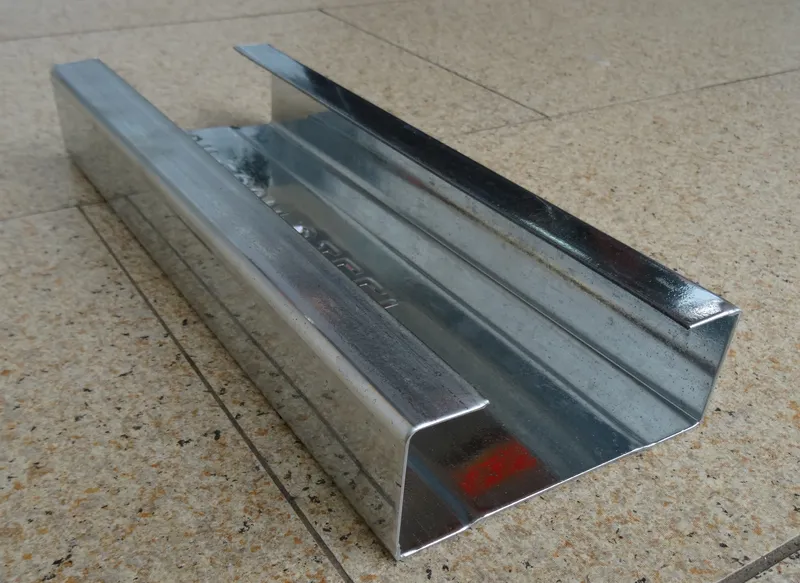

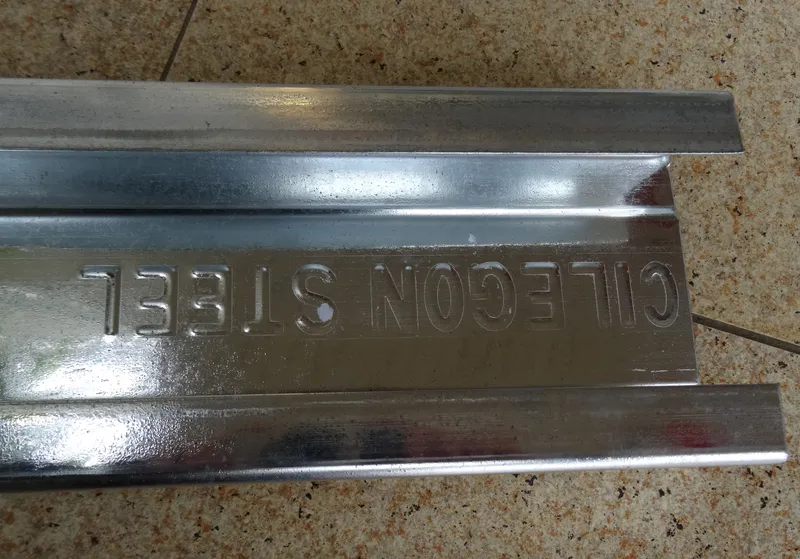

C purlin: what is it?

C purlins, also known as Cee purlins, are horizontal beams with a C-shaped cross-section that are used to form the wall and root joists of a building shell structure.

They provide support for the roofing sheet to keep it securely fastened and in place by sitting between the sheet and the structure.

C-formed purlins have the benefit of being lightweight, portable, and simple to install.

What is the purpose of C purlin?

They are frequently utilized in the construction of trusses, factories, roofs, civil houses, etc.