The C-shaped steel purlin machine is highly specialized mechanical equipment that focuses on the efficient manufacture of C-shaped steel, a critical light steel structural component in the building sector. C-shaped steel, with its distinct cross-sectional shape and outstanding structural performance, is essential in the construction industry, particularly in the design of roof support systems and wall skeletons. Its applicability is very broad. C-shaped steel, whether used for roof support in big commercial buildings or wall construction in residential areas, assures structural safety and durability by providing a steady support force and strong load-bearing performance.

The C-shaped steel purlin machine incorporates modern automated manufacturing technologies to enable a fully automated production process from raw material input to final product output. This effective manufacturing technology not only increases the production efficiency of C-shaped steel, but it also assures that each C-shaped steel purlin meets the exact length and specification requirements. At the same time, the machine is highly adaptable, allowing it to quickly adjust production parameters based on the specific needs of customers to produce C-shaped steel purlins of various specifications and lengths, meeting the construction industry’s increasingly diverse requirements.

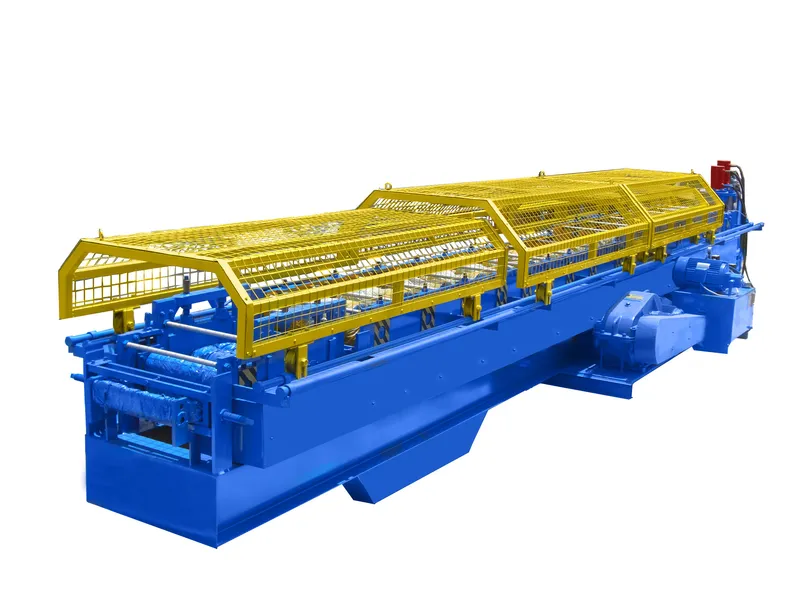

Main Components:

| Item | Name | Qty |

| 1 | Manual Decoiler | 1 |

| 2 | Feeding platform | 1 |

| 3 | Main forming system | 1 |

| 4 | Hydraulic cutting system | 1 |

| 5 | Hydraulic pump station | 1 |

| 6 | Electrical motor | 1 |

| 7 | PLC control system | 1 |

| 8 | Touch screen operation | 1 |

| 9 | Finished products receive table | 1 |

| 10 | Safety shield(optional) | 1 |

| 11 | Hydraulic decoiler(optional) | 1 |

| 12 | Automatic stacker(optional) | 1 |

Characteristics of C structure machine:

- High degree of automation: The C structure machine can achieve a series of operations such as automatic feeding, automatic molding, automatic shearing, and automatic discharge, which reduces manual intervention and improves production efficiency.

- High accuracy: The equipment adopts accurate control systems and mechanical structures, which can ensure that the C -shaped cricket bars produced are accurate and standardized, and meet the requirements of architectural design and construction.

- Strong adaptability: The C structure machine can produce different thickness and different width C -type bars, and can customize special specifications of special specifications according to customer needs, which has strong adaptability and flexibility.

- Energy -saving and environmental protection: The equipment adopts advanced production technology and materials, which can effectively reduce energy consumption and emissions, and meet the requirements of modern green production.

Equipment features

- Production efficiency: The C-shaped steel purlin machine can swiftly and efficiently create C-shaped steel bars in a range of dimensions and lengths. The changeover process is made easy and quick by its quick specification change capability, which significantly boosts production efficiency.

- Intelligent operation: The apparatus uses an automated control system, which makes it simpler to use and lowers the operator skill requirements. Simultaneously, the automated manufacturing process enhances product quality and decreases the likelihood of human mistakes.

- Energy conservation and environmental protection: The C-shaped steel purlin machine satisfies the environmental protection standards of contemporary manufacturing by being silent and pollution-free throughout the production process. Its effective manufacturing technique also contributes to lower production costs.

- Stability and Durability: The machinery is capable of meeting the demands of continuous production, operating steadily in a variety of challenging situations.

Equipment composition

The pieces that make up the C-shaped steel purlin machine are mostly as follows:

- Steel plates that need to be treated are placed on a passive unloading rack.

- The unloading rack foundation keeps the unloading rack stable while it is being processed.

- The steel plate is guided into the processing area by the feed introduction platform.

- Leveling device: to guarantee precise processing, level the steel plate.

- Forming machine: The steel plate is turned into C-shaped steel bars by means of precise machining.

- Punching tool: To suit certain requirements, punch holes in C-shaped steel bars.

- Forming and cutting tool: Cut the C-shaped steel bars into the desired length after processing.

- Hydraulic station: Supply the machinery with power.

- Computer control cabinet: Manage all of the equipment’s functions and operations from one central location.

Product application

C-shaped steel bars are often used in the following sectors as a light steel structural component in the construction industry:

- Roof support: C-shaped steel bars are appropriate for supporting structures of different roof types since they are straight and have strong resistance to bending and compression.

- Wall frame: To increase the wall’s stability and bearing capacity, C-shaped steel bars are used as frame components in wall building.

- Additional applications: Light steel structural goods like shelves and bridges may also be made using C-shaped steel bars.