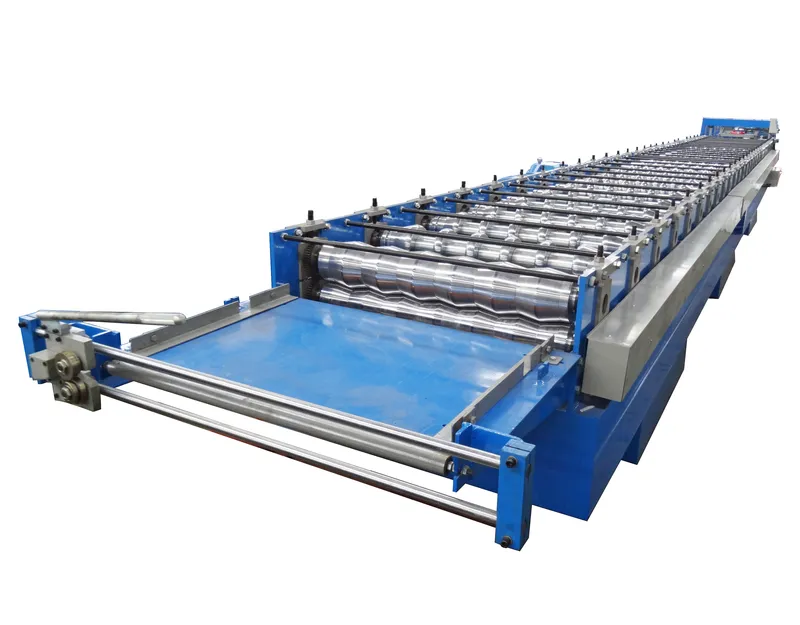

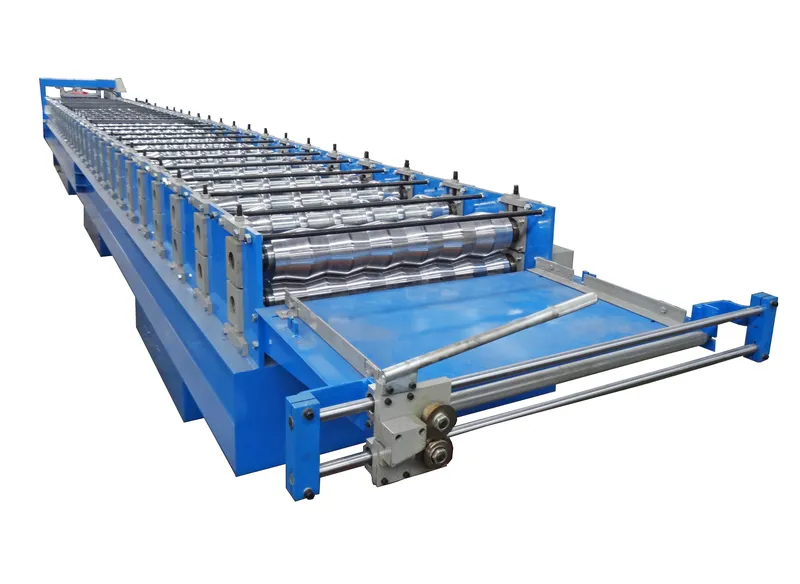

The corrugated roof sheet forming machine, as a professional metal forming equipment, focuses on producing high-quality corrugated metal sheets. It cleverly uses a series of precise rolling and forming technologies to transform the original metal coils into metal sheets with unique corrugated shapes. These corrugated metal sheets are not only beautiful, but also have excellent structural strength and durability, so they have been widely recognized and used in the construction industry.

The corrugated roof sheet forming machine provides high-quality corrugated metal sheet solutions for the construction industry with its efficient and high-precision production, simple operation, and energy-saving and environmental protection characteristics. It can not only meet the construction industry’s requirements for material quality and precision, but also reduce production costs and environmental pollution, and promote the sustainable development of the construction industry.

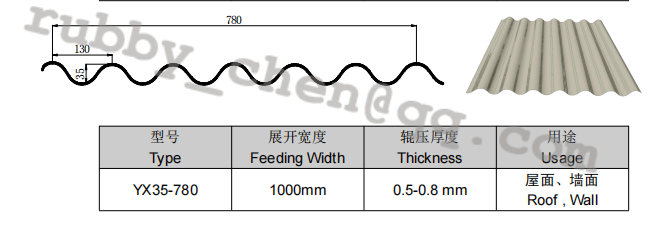

Machine Technical Parameter

| No. | Item | Parameter |

| 1 | Machine size | 7500*1780*1400mm |

| 2 | Machine weight | 7500kg |

| 3 | Machine power | 7.5kw |

| 4 | Hydraulic engine | 2.2kw |

| 5 | Roll speed | 0-20m/min |

| 6 | Roll stations | 24 |

| 7 | Roller material | 45#Steel |

| 8 | Effective width | customized |

| 9 | Feeding width | 1000mm |

| 10 | Voltage | 380V 50Hz 3PH/Customized |

| 11 | Material thickness | 0.5-0.8mm/Customized |

| 12 | Control System | Schneider/Delta/Customized |

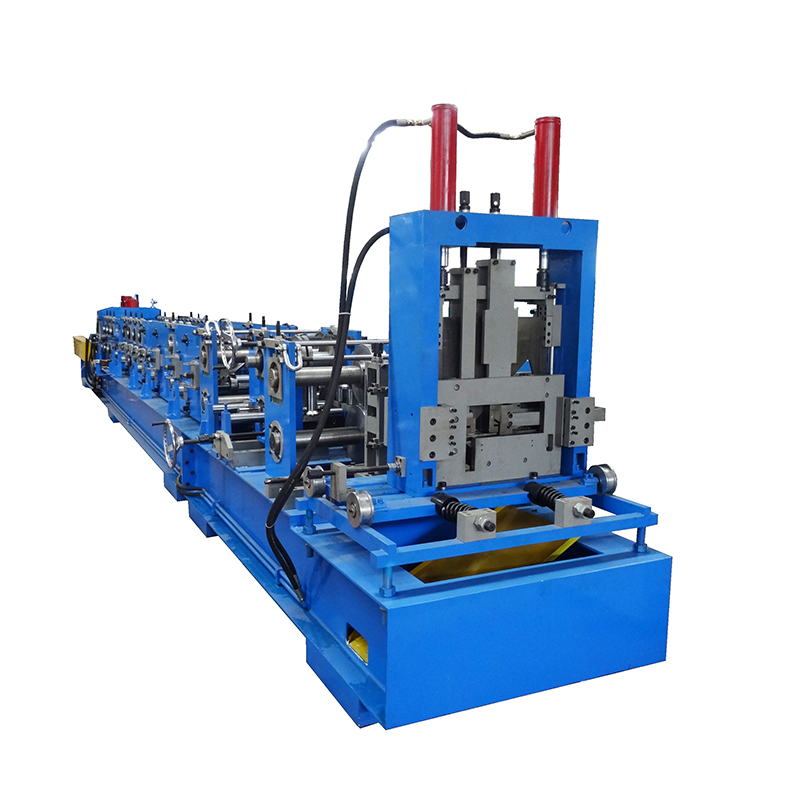

Profile of corrugated machine

Advantages

High-precision and efficient manufacturing

The corrugated roof panel forming machine has a reputation for being a very accurate and efficient manufacturing tool. The sophisticated mechanical design and exact control mechanism guarantee the metal coil’s precision and stability throughout the rolling and shaping procedure. In addition to increasing product yield, this also ensures that the corrugated metal sheets produced meet the exacting specifications of the construction industry in terms of size, shape, and performance.

basic functioning

Another notable aspect of the apparatus is how simple it is to operate. After a little instruction, users may quickly become proficient in using the equipment. The equipment’s control interface is simple to use and intuitive, making it easy to adjust various parameters quickly and conveniently. This greatly lowers labor costs and operation difficulty. For a variety of production requirements and scales, this makes the corrugated roof panel forming machine the perfect piece of equipment.

Conserving energy and safeguarding the environment

The corrugated roof panel forming machine actively heeds the call for energy conservation and emission reduction in light of the growing environmental consciousness of today. The equipment uses low-energy consumption, high-efficiency drive systems, and energy-saving materials, and it fully takes environmental protection factors into account during the design and manufacturing process. A clean and quiet production environment is ensured by the efficient control and processing of the equipment’s waste and noise during the production process. Because of this, the corrugated roof panel forming machine not only excels in terms of production efficiency but also helps to protect the environment.

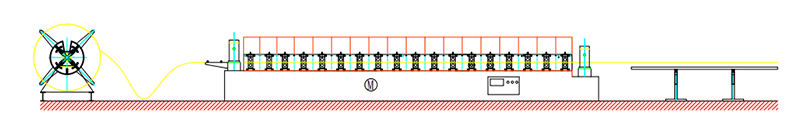

Work Flow

Decoiler→Feeding Guide Device→Pre-Cutting Device→Roll Forming System→Hydraulic Post Cutting Device→Exit Rack

Features of the Product

- Production efficiency: To fulfill the demands of large-scale building projects, the corrugated roof sheet roll forming machine can create corrugated metal sheets fast and effectively.

- High-precision forming: To guarantee that the corrugated metal sheets have accurate dimensions and regular corrugations, the equipment uses cutting-edge rolling technology. This increases the quality of the final product.

- Simple operation: The equipment is simple to use and run, which lowers labor expenses and operation difficulties.

- Energy conservation and environmental protection: The apparatus satisfies current energy conservation and environmental protection standards by producing little noise and using less energy while in use.

Application

- The corrugated forming machine is a device designed specifically to create corrugated sheet. Rolling transforms the metal plate into wave shaped plate. Corrugated boards are frequently used in building, decorating, and packaging.

- The corrugated machine is made up of four components: the rack, the transmission system, the roll pressure system, and the cutting system. The rack is the device’s main structure that supports and holds additional components. The transmission system uses motors and reducers to power the roller pressure system. The roller system comprises of several rollers. The metal plate is corrugated as a result of the roller’s rotation and compression. The cutting system is used to cut the pressed wave board to the specified length.

- The corrugated machine has several benefits, including high production efficiency, ease of operation, and effective suppression. At the same time, it may be tailored to meet unique needs, producing corrugated of various specs and shapes. As a result, the roller roll molding machine has found widespread application in building, decoration, and packaging.

-16-.webp)