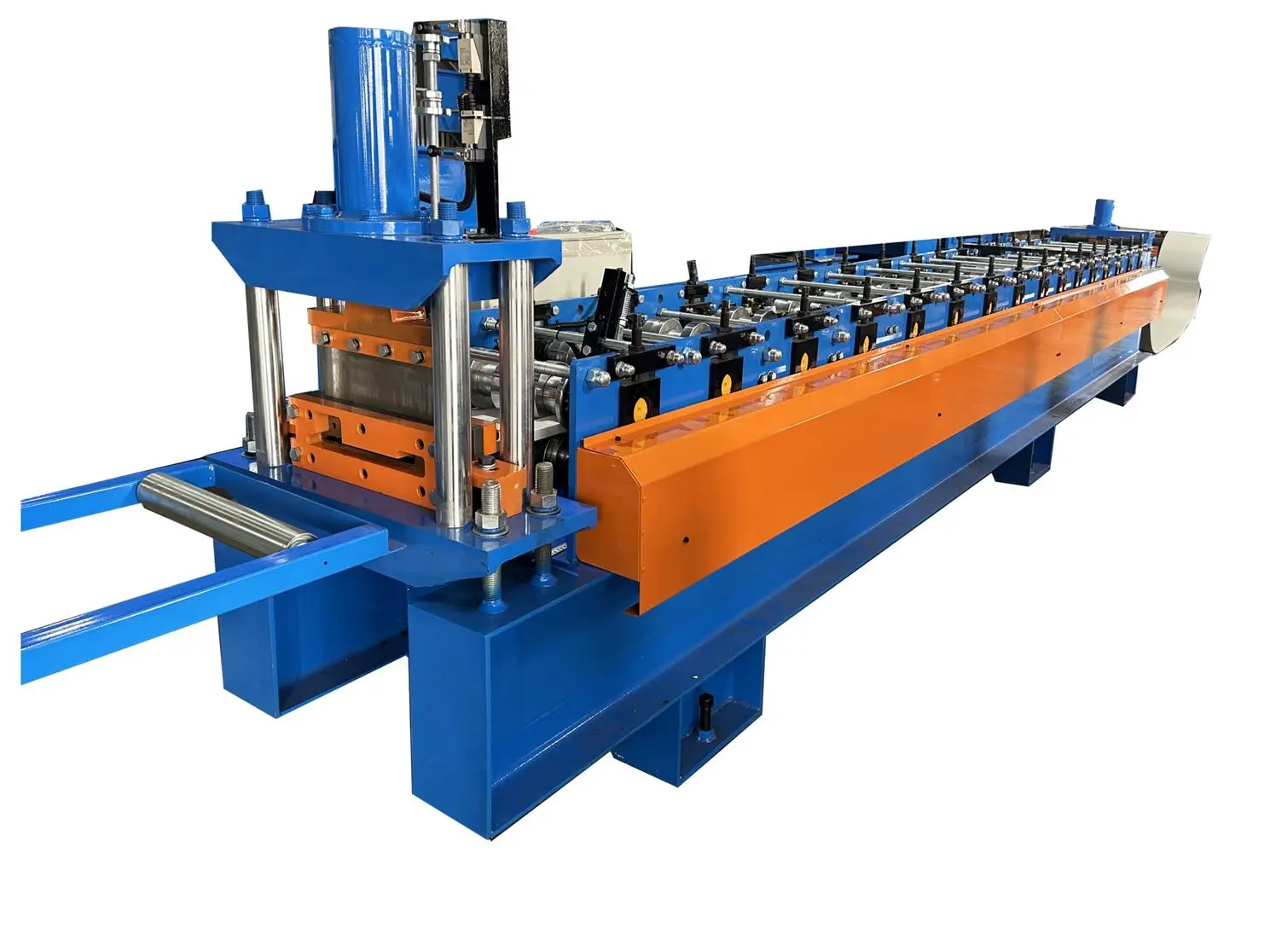

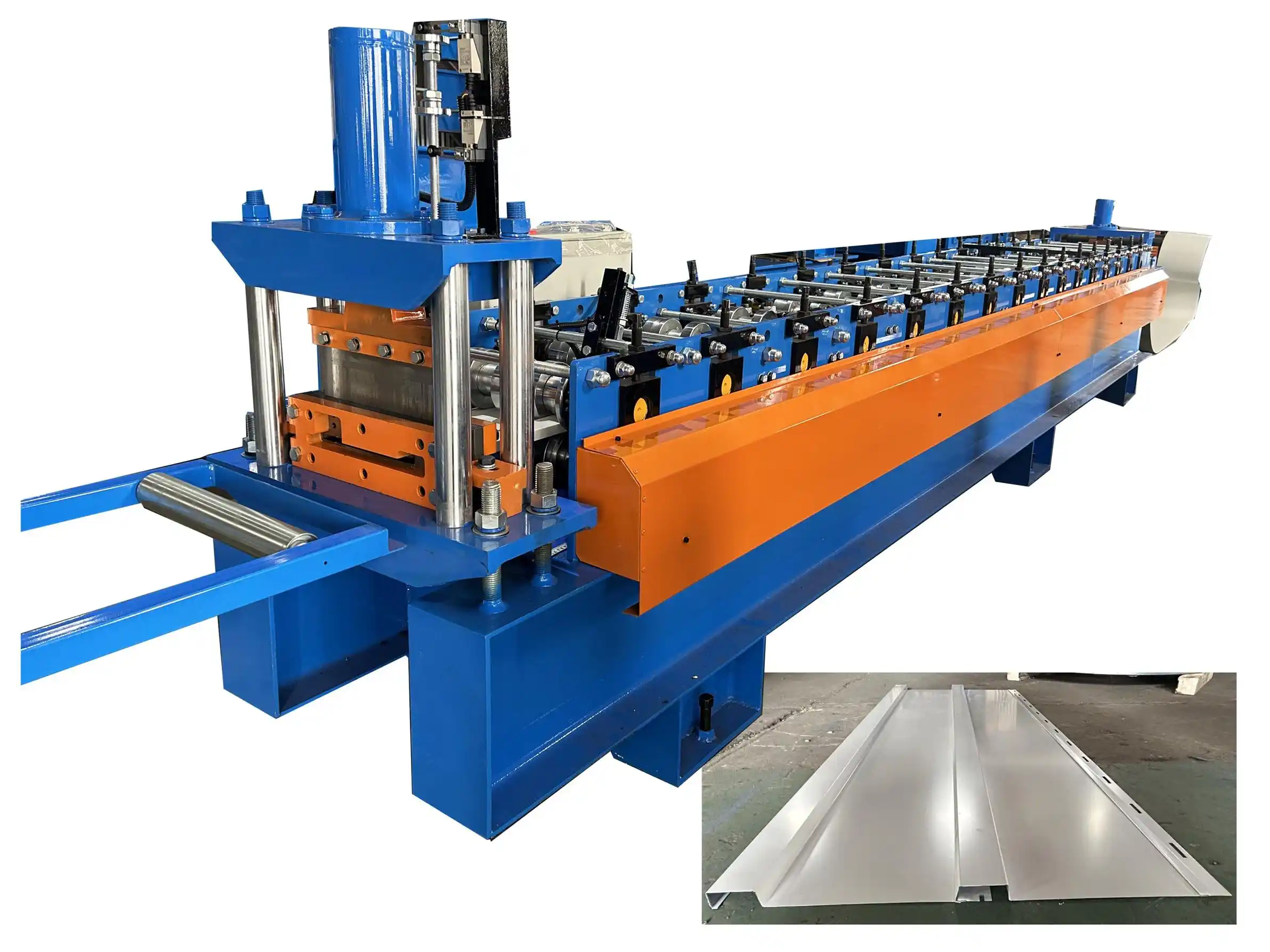

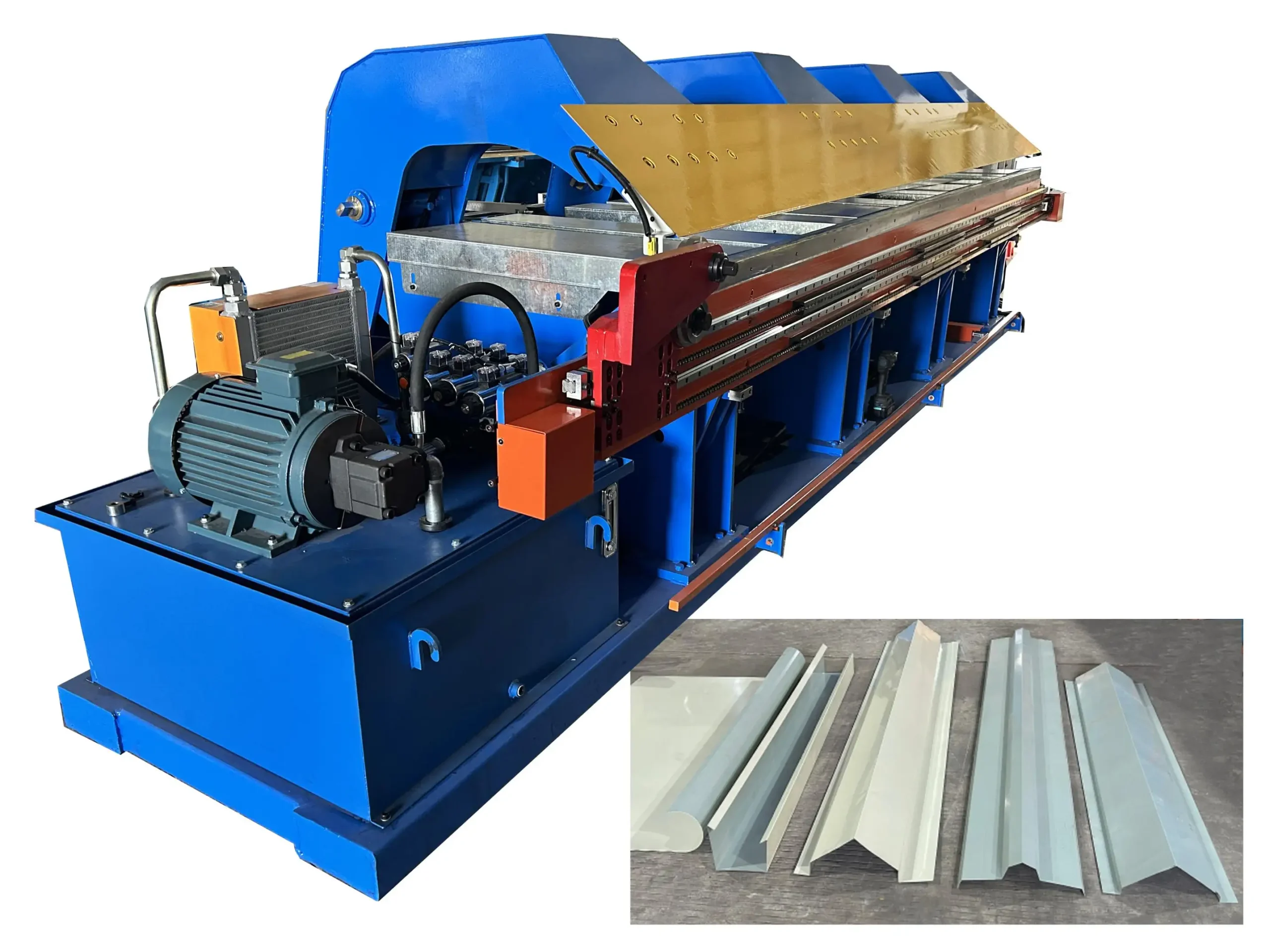

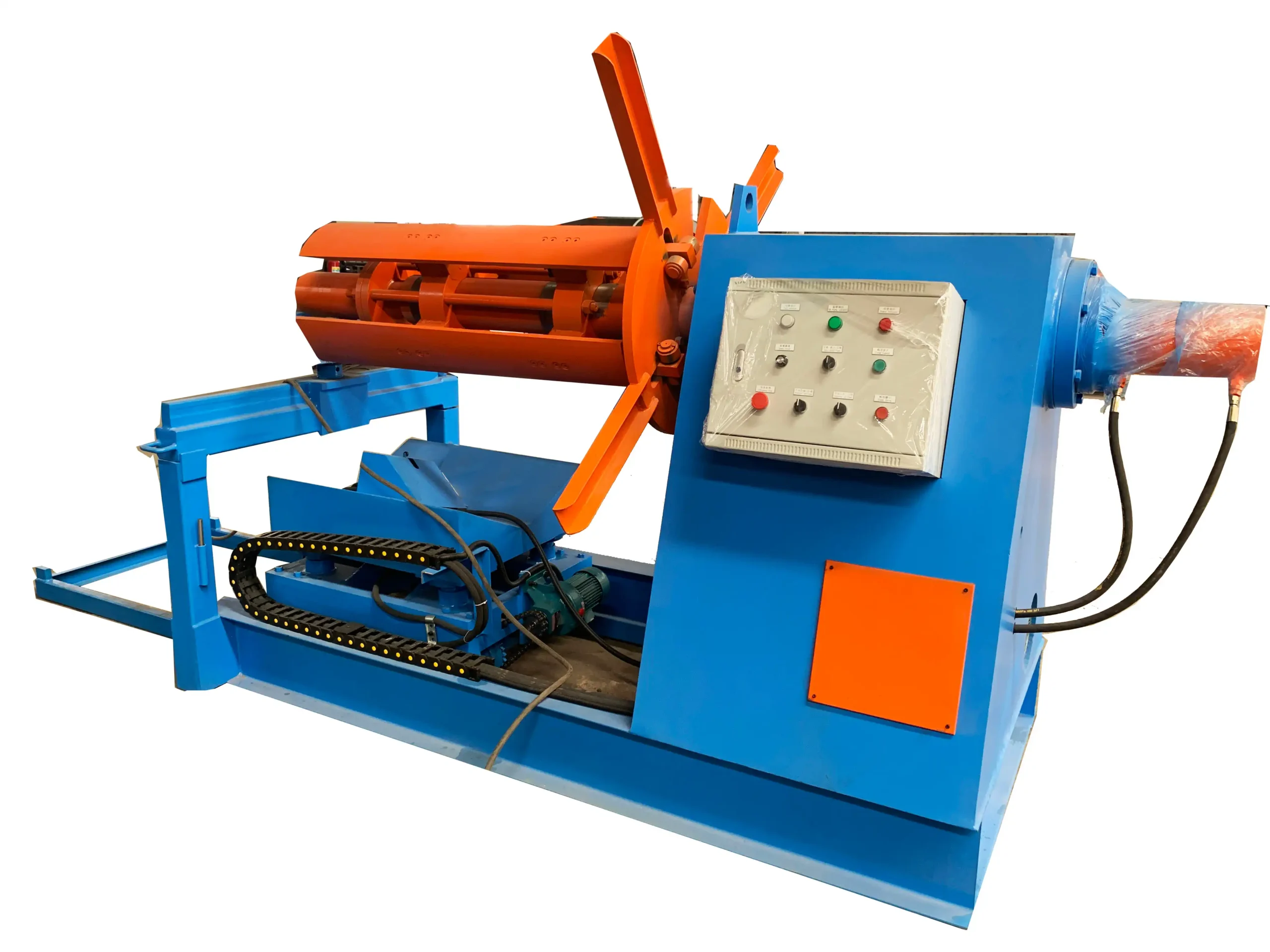

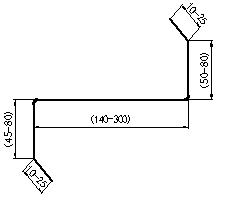

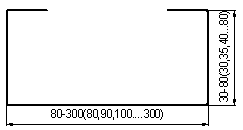

The high-quality automatic changeover CZ purlin forming machine is an efficient, versatile, high-quality mechanical equipment that can meet the needs of different engineering projects for C purlins and Z purlins. The equipment adopts advanced automation technology to achieve efficient and accurate purlin forming. Through the preset program, the equipment can automatically complete the entire process from material input to finished product output. The automatic changeover design allows the equipment to flexibly switch between C purlins and Z purlins to meet the needs of different projects. The use of high-quality materials and precision processing technology ensures that the purlins produced have high precision, high strength and excellent durability.

Advantages

- The CZ integrated purlin machine is a unique-tile-pressing machine that combines the functionality of the C-type and Z-type machines. It combines the benefits of numerous pieces of equipment, considerably increases production efficiency, and lowers production costs.

- The CZ integrated purlin machine’s main features include cutting without changing the tool, extremely fast replacement speed (any replacement can be completed in three minutes), a high degree of adjustability (including the belly, wing edge, and other parts), and the ability to quickly switch between the C and Z sections. Furthermore, its coaxial construction significantly decreases the height on both sides of the broken axis, making the equipment more compact.

- The CZ integrated purlin machine consists primarily of a passive feeder, a flattening device, a punching device, a post-forming cutting device, a hydraulic station, and a sophisticated computer control system. The device uses automated flying saw punching technology, which is simple and fast to use. This machine produces C-type and Z-type steel purlins using the steel plate cold pressing technique to guarantee consistency of wall thickness, and the size can be flexibly modified according to demands, resulting in good pressure resistance.

- C and Z-type steel purlins are not only lightweight and inexpensive but also simple to build. They may be precisely cut to the desired length in the processing factory and then delivered straight to the building site, significantly simplifying the construction process and increasing engineering efficiency.

- The CZ type integrated purlin machine’s great performance has made it extensively employed in various engineering disciplines such as buildings, bridges, tunnels, and so on, making it a vital and significant piece of equipment in today’s construction industry.

Machine Components

1. Feeding and Leveling Device

Side wall thickness: Q235 t25mm; tie rod:ф20

Shafts manufactured from 45# steel,

Diameter=φ115mm, Tone plated with hard chrome coating, precision machined

2. Hydraulic Pre-Cutting & Punching device

Pre-punching and pre-cutting devices share the hydraulic system

Hydraulic motor:7.5kw,

Hydraulic pressure:16Mpa

Punching and Cutting tool material: mold steel Cr12MoV

3-cylinder hole punching system for punching holes on web and flange

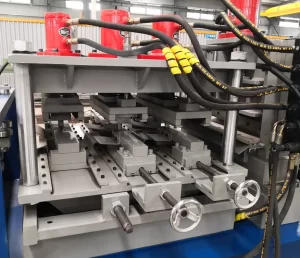

3. Main machine

Shafts Diameter = 95, precision machined

Gear/Sprocket driving

Main Servo Motor = 30kW

Speed reducer motor:K series;

Size changing motor: 6 pieces,

Automatically controlled by a computer system

Sliding block: 150 * 150mm

4. Post Hydraulic Cutting Device

Post to cut, stop to cut

One cutter could cut all forming sizes

5. PLC Computer Control System

Cut-to-Length Tolerance≤±1 mm

Control Voltage: 24V

Application scope of the CZ-type purlin machine.

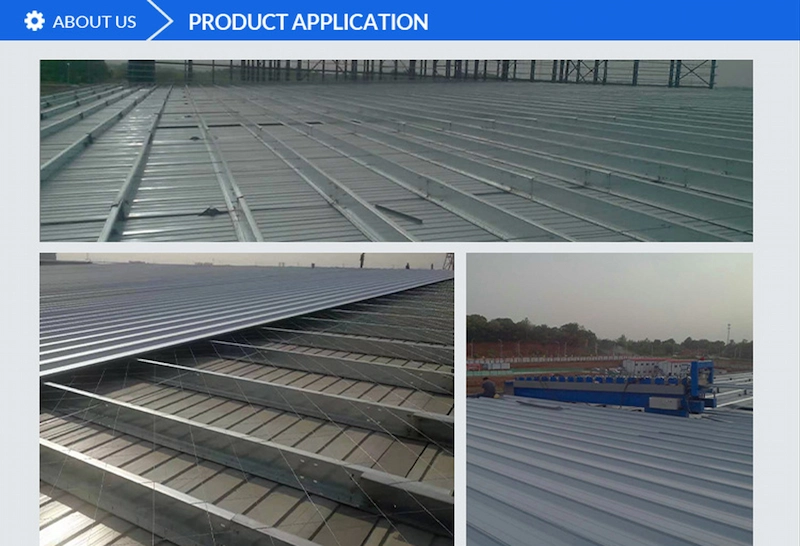

- Construction: CZ-type purlin machines produce C- and Z-type steel purlins for building constructions. They are used to support beams and columns, as well as roofs and wall frames. These steel purlins are lightweight, sturdy, and easy to install, increasing construction efficiency while cutting costs.

- Bridge engineering uses CZ steel purlins for bridge support structures, deck pavement, guardrails, and other parts. Its excellent bearing capacity and stability meet bridge engineering material requirements.

- Tunnel engineering requires a number of supporting structures and protective facilities. CZ steel purlins are lightweight and durable, making them useful for tunnel construction. They may support the roof, reinforce the side walls, and add tunnel ventilation, drainage, and other systems.

- A robust roof and wall construction are required when building a factory or warehouse. CZ steel purlins are ideal for these applications. They can easily create bright, spacious rooms that withstand wind and earthquakes.

- CZ steel purlins may also be used to construct stadiums, exhibition halls, greenhouses, and other constructions. CZ purlin machines are crucial construction equipment because of their versatile uses and configurable features.