Features of the Door Guide Rail Machine

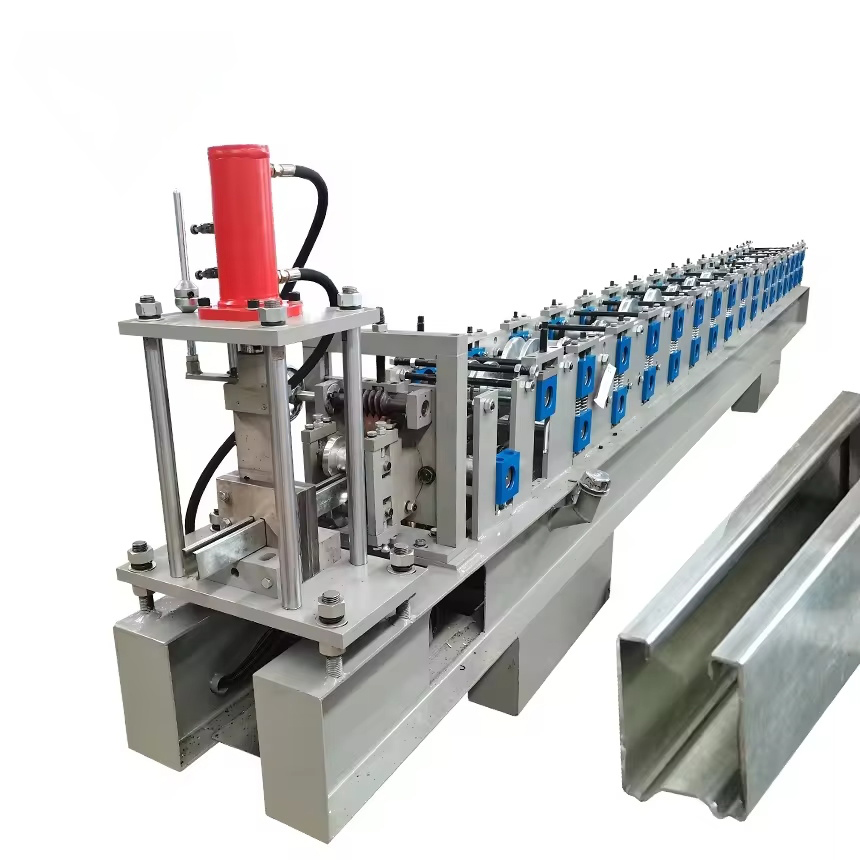

The guide rail forming machine for rolling shutter doors is specifically designed to produce precise and efficient rolling shutter rails using roller forming technology. This machine ensures that the manufactured rails meet exact specifications.

The equipment typically consists of a frame, roller pressing system, drive system, control system, and other essential components. During operation, the material is fed into the roller pressing system through a feeding device. It is then progressively shaped as multiple sets of rollers continuously deform the material to the required size and shape. Simultaneously, the drive system powers the entire machine, while the control system monitors and adjusts the machine’s performance, ensuring a stable and safe manufacturing process.

Flow Chart of Door Guide Rail Machine

Decoiler – Feeding Guide Device – Rolling Forming System – Hydraulic Cutting Device – Run-Out Table

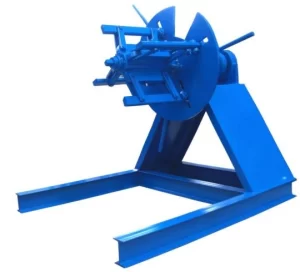

- Decoiler: The decoiler is responsible for unwinding the raw material, typically metal coils, and preparing it for the production process. It ensures a smooth and steady feed of material, minimizing interruptions and maximizing efficiency.

- Feeding Guide Device: This device accurately guides the material from the decoiler into the rolling forming system. It ensures proper alignment and prevents deviations during the feeding process, maintaining precision throughout production.

- Rolling Forming System: The heart of the machine, this system utilizes multiple sets of rollers to gradually shape the raw material into the desired profile. As the material passes through each set of rollers, it is precisely formed into the required shape, ensuring uniformity and consistency.

- Hydraulic Cutting Device: Once the material has been formed, the hydraulic cutting device performs precise, high-speed cutting to achieve the required length. This system ensures clean and accurate cuts without deforming the final product.

- Run-Out Table: The run-out table serves as the final stage, collecting the finished product after it has been cut. It allows the formed pieces to smoothly exit the production line, ensuring safe handling and efficient packaging or further processing.

Advantages of Door Guaid Rail Machine

As a standout in modern industrial production, the door guide rail forming machine is widely used in industries such as garage doors, roller shutter doors, elevators, and lift shafts, providing highly efficient and precise solutions for guide rail manufacturing. Here are the key advantages of the door guide rail forming machine:

- High-Efficiency ProductionThe door guide rail forming machine adopts advanced automation technology, allowing it to efficiently complete processes such as guide rail forming, cutting, and leveling. Compared to traditional manual production methods, this equipment reduces cumbersome and time-consuming manual operations while minimizing human error, thus improving overall production efficiency and product quality.

- Precision ManufacturingEquipped with a high-precision transmission system and forming molds, the machine ensures accurate guide rail formation and dimensional consistency. During production, the machine automatically adjusts the shape and size of the forming molds based on preset parameters, producing guide rails that meet customer specifications. This precision manufacturing capability enhances product quality and stability while catering to the diverse needs of different industries.

- Cost ReductionThe automated production method of the door guide rail forming machine significantly reduces the frequency and intensity of manual operations, lowering labor costs. Additionally, the machine’s high efficiency and precision reduce material waste and loss, further cutting production costs. This allows companies to achieve higher economic benefits while maintaining product quality.

- Ease of Maintenance and CareThe machine’s design is rational and compact, making it easy to maintain and care for. All components are standardized, facilitating routine cleaning, inspection, and repair. Moreover, the equipment is equipped with a fault self-diagnosis system, which monitors the machine’s operating status in real time, promptly identifying and resolving potential issues to ensure stable operation.

- Wide Range of ApplicationsThe door guide rail forming machine is not only suitable for the door industry, including garage and roller shutter doors, but it is also widely used in the construction sector for elevators and lift shafts. Its high efficiency, precision manufacturing capabilities, and broad application range make it an indispensable tool in modern industrial production.

Component of Door Guide Rail Machine

Machine Parts

1) Feeding

2) Rollers of guide rail machine

3) Forming cutter

4)PLC Control system (2 type for choosing)

Easy to operate

Shutter Door MachineDecoiler (2 type for choosing)

- Manual decoiler 2. Hydraulic decoiler

Applications of rolling up door machine