The double-layer roofing machine is an amazing example of highly integrated and innovative manufacturing equipment since it can generate two distinct profiles at the same time. This equipment’s design deftly blends contemporary mechanical technology with manufacturing principles in an effort to provide users with a notable boost in production efficiency, cost and space savings, flexibility, and convenience to accommodate a wide range of customer demands.

Advantages

increased effectiveness of production

By handling the manufacturing chores of two distinct profiles concurrently within a single production cycle, the double-layer roofing machine significantly increases overall production efficiency. It can produce more products simultaneously than traditional single profile production equipment, which shortens the production cycle, speeds up product launch, and opens up important market opportunities for businesses.

Savings on both space and money

The double-layer roofing machine has an efficient and compact design that minimizes the amount of space needed for two devices to produce two profiles independently. This design helps to optimize the production layout and enhance the overall smoothness of the production line in addition to reducing the amount of floor space needed for the production site. Effective cost management is achieved by reducing the amount of equipment and the associated energy consumption, maintenance expenses, and personnel costs in proportion.

satisfying the adaptable demands of consumers

The high degree of flexibility of the double-layer roofing machine is one of its main features. It can effortlessly switch to produce profiles of various materials, shapes, sizes, and even colors. It can also swiftly modify production parameters in accordance with the specific needs of customers. In addition to satisfying the market’s growing diversity of product needs, this flexibility helps businesses react swiftly to shifts in the market and grab hold of fresh ventures. The ideal option for clients who need to make different goods on the same production line is without a doubt the double-layer roofing machine.

What is a double roofing machine?

SKD proudly supplies double roofing roll forming machines to high-end markets at home and abroad, such as Asia, Australia, Middle East, Africa and Europe.

Depending on the country, the rib profiles range from 5, 6, 7, 8, 9 and 10, among which 5 rib profiles are the most common. The type of double metal roof depends on the customer’s product. Standard trapezoidal roof. Corrugated roof or metal roof tiles.

Double roll forming machine has two layers or two-stage roll forming parts, so it is also called double roll forming machine, and double roll forming machine and 2 in 1 double roofing panel machine are also well-known names because the machine produces two metal sheets.

Double machine has two profiles in one machine to make double roofs, saving space, time and money.

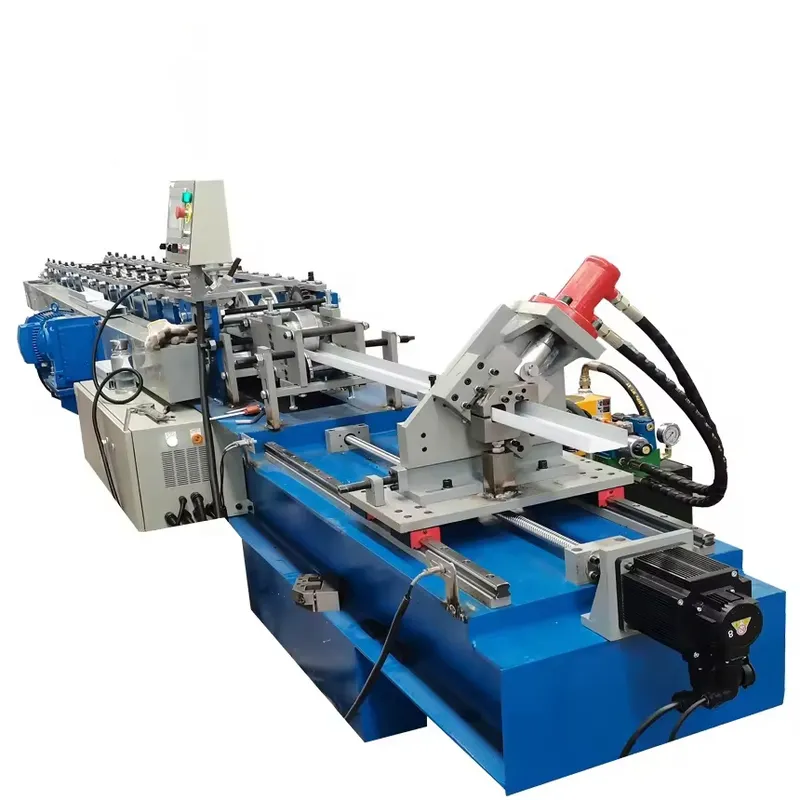

Detailed picture of double-layer roll forming machine

Machine parts

1) Double-layer roof machine with pre-cutter

2) Double-layer roof panel machine roller

The roller is made of high-quality bearing steel GCr15, processed by CNC lathe, heat-treated, and with hard chrome coating.

3) Double-layer roof panel machine rear cutter

Made of high-quality mold steel Cr12 after heat treatment

Hydraulic motor: 3.7KW, hydraulic pressure range: 0-16Mpa

4)PLC control system

Easy to operate

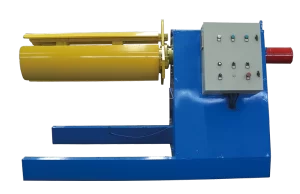

5) Double-layer roof panel machine unwinder

Manual unwinder: one set

No power, manual control of steel coil inner hole shrinkage and stop

Maximum feed width: 1250mm, steel coil ID range 480mm±30mm

Production capacity: maximum 5 tons

5-ton hydraulic unwinder, with or without car optional

Application scenarios

- Residential buildings: Double-layer roof panels may successfully keep out water, insulate, and keep a home warm while also enhancing comfort.

- Industrial buildings: To fulfill the demands of industrial production, double-layer roof panels may offer strong insulation and heat insulation effects in industrial buildings like factories and warehouses.

- Agricultural buildings: The seamless advancement of agricultural output is aided by the use of double-layer roof panels for the walls, roofs, and other components of agricultural buildings.

- business buildings: To satisfy the demands of business operations, double-layer roof panels in commercial buildings may provide spatial comfort as well as energy-saving and environmental protection impacts.

Advantages:

- High production efficiency: By pressing two layers of colored steel plates simultaneously, the double-layer roof panel machine significantly increases production efficiency. In order to satisfy consumer demand, producers can fulfill a high volume of requests quickly thanks to this effective manufacturing technique.

- Excellent product quality: The double-layer tile pressing machine has strong stiffness and can adjust the space between the calender rollers because it employs a high-precision, thick-walled, three-roller mirror calender. As a result, the high-quality, smooth-appearing, uniformly corrugated, and highly used double-layer roof panels are manufactured.

- Production that is adaptable and diverse: The double-layer tile pressing machine can create roofing panels, color steel tiles, and other products that are appropriate for a variety of projects. It can also generate single- or double-layer steel tiles. Furthermore, color steel plates with various profiles may be created to satisfy the wide range of market demands by simply switching out the high and low racks.

- Simple operation and maintenance: Manufacturers can simply manage equipment and minimize downtime thanks to the benefits of the double-layer tile pressing machine, which include simple operation, maintenance, mechanical debugging, and mold replacement.

- High degree of automation: To achieve production information management, the double-layer tile pressing machine uses sophisticated automated control software. To increase the automation system’s performance, the complete unit automation control system uses a highly linked network.