Key Functional Analysis

- Automatic Cutting: Utilizing advanced cutting technology, the scaffolding panel roll forming machine accurately cuts raw materials to preset lengths, ensuring precise product dimensions.

- Uncoiling: The machine automatically unwinds the coil material, providing flat raw materials for subsequent processes.

- Leveling: After uncoiling, the material may have slight bends or irregularities. The leveling process ensures that the material achieves the desired flatness before proceeding to further processing.

- Servo Feeding: Employing a servo system to control feeding speed guarantees the stability and continuity of the material during processing, thereby enhancing product quality and production efficiency.

- Punching: The equipment can punch holes at designated locations based on the design requirements of the scaffolding panels, fulfilling needs for connections and fastening.

- Continuous Roll Forming: Through a series of continuous pressing and forming with rollers, the raw materials are processed into scaffolding panels that meet specified standards.

Equipment Advantages

- High Production Efficiency: With a high level of automation, the machine enables continuous production, significantly increasing the output capacity of scaffolding panels.

- Stable Product Quality: Precise cutting, leveling, and roll forming ensure product consistency and stability.

- High Flexibility: The equipment can be customized and modified according to different customer needs, accommodating personalized technical requirements.

Customer Customization

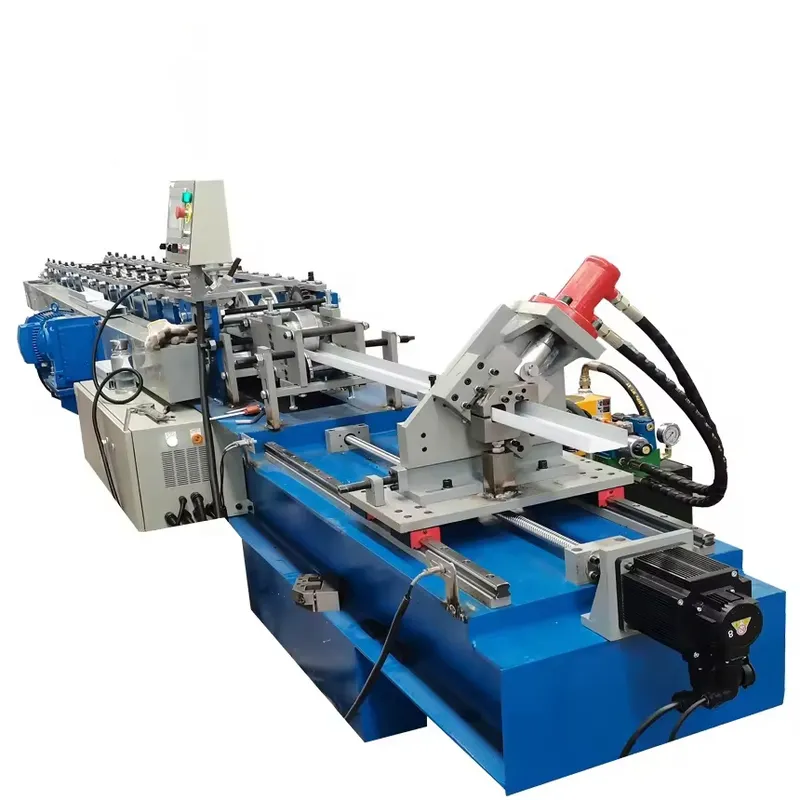

One piece of specialized machinery utilized primarily in the manufacture of pedals is the pedal roll forming machine. It makes material shaping by roller extrusion possible. An extensive overview of the pedal roll forming machine is provided below: Composition of equipment: The rollers, feeding and discharging devices, control systems, transmission systems, and other components make up the majority of the pedal roll forming machine.

Application

Component of Foot Pedal Roll Forming Machine

Machine Parts

1) Rollers of Machine

Rollers are made of high-quality bearing steel GCr15, CNC lathed, heat-treated, and available with hard chrome coating.

2) Forming cutter

3)Hydraulic system

4)PLC Control system (2 type for choosing)

Easy to operate

5)Decoiler (2 type for choosing)

1. Manual decoiler 2. Hydraulic decoiler

Our Worksop