We are a professional roll forming machine manufacturer, dedicated to providing customers with high quality solutions for guide roll forming machine and guide rail forming machine. Not only do we have advanced production technology and equipment, but we also accept ODM (Original Design Manufacturer) and OEM (Original Equipment Manufacturer) customization services to meet the diverse needs of our customers. Whether you need a standard guide roll forming machine or a guide rail forming machine with specific specifications, we will create a satisfactory product for you with our professional technology and excellent service.

Flow chart of guide roll forming

Feature of guide rail forming machine

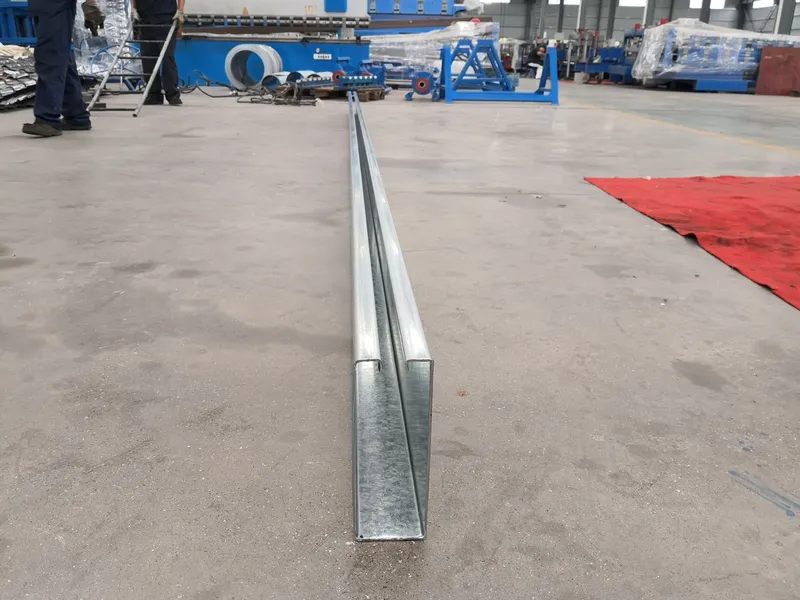

The guide rail forming machine, which makes guide rails, has a solid frame, a flexible workbench, accurate guide rail tracks, and efficient processing processes including stamping, milling, forming, and cutting. Together, these devices correctly shape raw materials into guide rail forms and sizes that fulfill requirements.

Guide rail forming machines are essential in rail transportation, automation, industrial machinery, and other industries due to their accuracy, efficiency, and automation. It can boost guide rail production efficiency and product quality, supporting the fast growth of contemporary manufacturing.

Guide rail forming machines upgrade and innovate as science and technology develop. Future guide rail forming machines will be smarter, more accurate, and more efficient to fulfill complex and diversified guide rail production demands. They will improve automation and intelligent production by using more modern control systems and sensor technologies to enhance the manufacturing business.

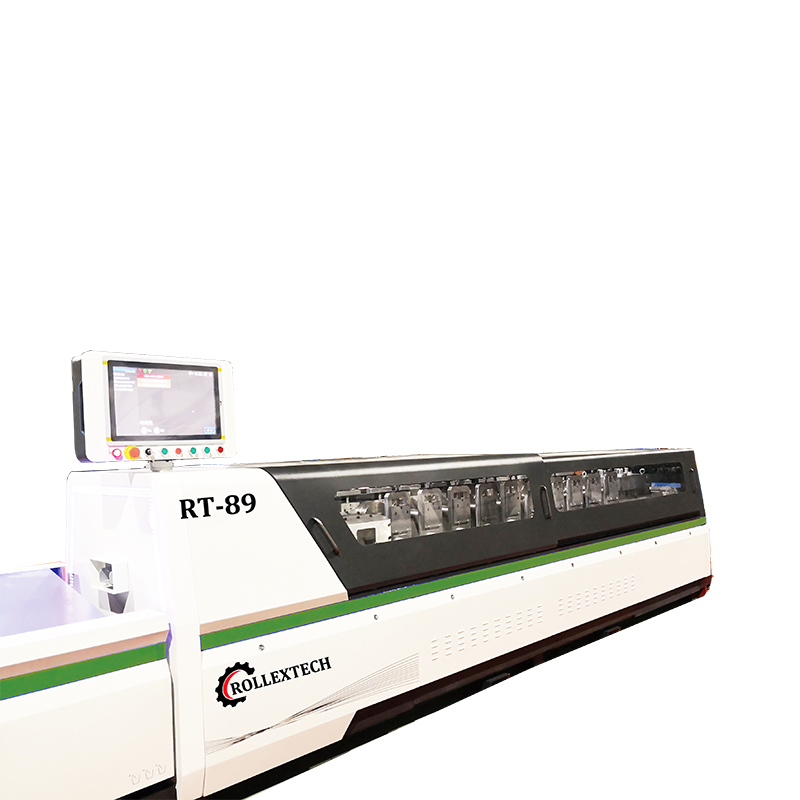

Components of a Roll Forming Machine

A roll forming machine is a sophisticated piece of equipment that consists of several crucial components to ensure smooth and precise operation. Here are the main components of a roll forming machine:

Feeding Mechanism:

This component is responsible for feeding the raw material, typically a metal strip, into the machine. It ensures a constant and smooth flow of material into the forming process.

Rollers of the Machine:

Rollers are the heart of the roll forming process. They are precisely designed and arranged in a series to gradually shape the metal strip into the desired cross-section. Each roller performs a specific task in the overall forming sequence.

Forming Cutter:

After the material passes through the rollers and acquires the desired shape, the forming cutter is used to cut the shaped metal into individual pieces or lengths. This cutter ensures accurate and consistent cutting of the formed material.

PLC Control System (Two Types Available):

The Programmable Logic Controller (PLC) is the brain of the machine. It controls and coordinates the operation of all the components, ensuring precise synchronization and optimal performance. The PLC system offers two types of control options, allowing users to choose the one that best suits their needs.

The PLC system is designed for ease of operation, providing a user-friendly interface and intuitive controls.

Decoiler (Two Types Available):

The decoiler is responsible for unwinding the metal coil and feeding it into the machine. There are two types of decoilers available:

Manual Decoiler: This type of decoiler requires manual operation to unwind the coil. It is suitable for smaller machines and lower production volumes.

Hydraulic Decoiler: A hydraulic decoiler uses hydraulic power to unwind the coil automatically. It provides higher efficiency and productivity, making it ideal for larger machines and higher production requirements.

About Us

We are a leading company specializing in the manufacture of roll forming machines, committed to providing customers with high-quality roll forming machine solutions. As a leader in the industry, we rely on our outstanding technical strength and superb craftsmanship to continuously meet customers’ various needs for roll forming machines.

As an ODM (original design manufacturer) and OEM (original equipment manufacturer), we have flexible production models and customized service capabilities. Whether it is a standard roll forming machine product or customized development based on the specific needs of customers, we are able to respond quickly and provide satisfactory solutions. We are well aware that each customer’s business needs and project characteristics are unique, so we always adhere to customer-centricity and provide personalized services.

Our roll forming machines are widely used in multiple industry fields, including rail transportation, automation equipment, industrial machinery, etc. These equipment have won the trust and praise of customers with their high precision, high efficiency and high automation. We always adhere to quality as the core, continuously improve the performance and quality of our products, and ensure that each roll forming machine can meet customer expectations and requirements.