The notion of “guide rails” is shared by the guide rails in rolling shutter doors and the guide rail roller press, although there are important distinctions between their purposes and applications. The guide rail roll forming machine is a piece of machinery used in industrial manufacturing, although its primary function is to guide and assist the rolling shutter door’s movement.

While the guide rail roller press is an industrial production tool with high efficiency, energy savings, a compact construction, and easy operation, the guide rail also serves as a means of movement guidance, wind protection, safety protection, and structural integrity maintenance for rolling shutter doors. The terms “guide rails” are used in both, although their purposes and applications vary greatly.

Features of Guide Rail Roll Forming Machine

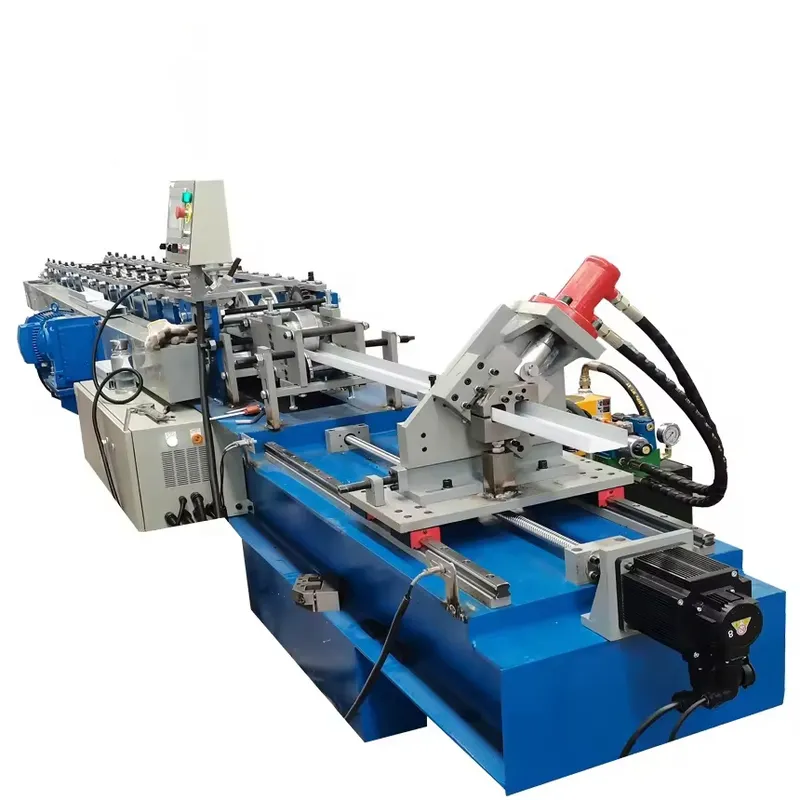

The rolling door guide rail forming machine is specifically designed to manufacture guide rails for rolling doors using advanced roll forming technology. It efficiently and precisely produces guide rails that meet strict quality standards. The machine is primarily composed of a frame, roll forming system, driving system, and control system.

The working principle involves feeding the material through a guiding mechanism into the roll forming system, where it is gradually shaped by a series of rollers into the desired form and dimensions. The driving system powers the machine, while the control system monitors and adjusts the operation to ensure consistent stability and safety throughout the production process.

Guide Rail Roll Forming Machine Production Process:

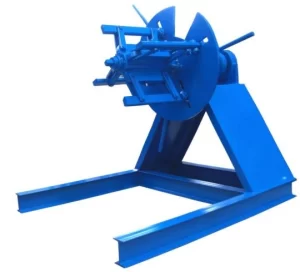

- Unwinder: This vital piece of machinery is in charge of smoothly unwinding the coiled material, supplying a steady stream of raw materials for further processing. Because of its accurate functioning, the material is protected against wrinkling and damage throughout the unwinding process, providing a strong basis for the shaping process that follows.

- Feed guide device: The feed guide device deftly directs the material into the roll-forming region while acting as a bridge between the unwinder and the roll-forming system. By preventing deflection or jamming throughout the transmission process, its ingenious design guarantees that the material maintains a steady course, assuring the effectiveness and quality of roll-forming.

- The central component of the whole manufacturing line is the roll-forming system, which uses a number of carefully crafted and constructed rollers to progressively compress and shape the material. In order to progressively mold the material into the correct final form, these rollers cooperate in accordance with established methods and parameters, guaranteeing the precision and consistency of the final result.

- Hydraulic cutting equipment: This device is essential when the roll-forming process is finished. It employs the hydraulic system’s strong force to precisely and steadily cut the completed guide rail to the desired length. This stage significantly increases manufacturing flexibility and efficiency while also guaranteeing the product’s dimensional correctness.

- Output station: The output station, the final stop on the production line, is in charge of moving the completed rails to storage or the subsequent stage in a safe and organized manner. Its design ensures the stability and safety of the final product during transportation by taking into account all of the product’s features and transportation needs. The output station may also be easily adjusted to accommodate goods with varying weights and sizes at the same time.

Advantages of the Guide Rail Roll Forming Machine

Guide rail roll forming machines are widely used across industries such as garage doors, rolling doors, elevator rails, and lift shafts. These machines enable accurate manufacturing of guide rails, improving production efficiency while reducing manual operations and overall production costs.

The guide rail forming machine offers the following advantages:

- High Production Accuracy: Multiple roller systems and precise control ensure that the shape and dimensions of the guide rails meet exact specifications.

- Efficient Production: The continuous roll forming process allows for rapid production, catering to high-volume manufacturing needs.

- Cost-Effective Operation: By reducing manual labor and material waste, the machine lowers the total production cost.

- Versatility: It can produce a variety of shapes and sizes of guide rails, making it adaptable to different industry needs.

Application Areas

The guide rail roll forming machine finds applications in various sectors, including garage doors, rolling doors, elevator guide rails, and other systems requiring accurate guiding and protective components. These machines enhance production efficiency and ensure that products are durable and reliable.

Component of Guide Rail Machine

Machine Parts

1) Feeding

2) Rollers of guide rail machine

3) Forming cutter

4)PLC Control system (2 type for choosing)

Easy to operate

Shutter Door MachineDecoiler (2 type for choosing)

- Manual decoiler 2. Hydraulic decoiler

Applications of Guide Rail Roll Forming Machine