Heavy Duty Purlin Machine, a high-quality and cost-effective model of CZ interchangeable machines, has multiple advantages and functions to meet the needs of producing C purlins and Z purlins. The heavy-duty fully automatic CZ purlin roll forming machine not only has high-quality characteristics such as high-quality materials, advanced technology and high automation, but also has high cost-effectiveness, meeting different production needs through multi-functional design and reasonable price.

High-quality features

- Selected high-quality materials: The main components of the whole machine are meticulously crafted from high-strength, wear-resistant materials. These materials not only offer exceptional fatigue resistance, but they also keep stable physical qualities under hard working situations, guaranteeing that the equipment continues to operate well and remain stable over time.

- Advanced roll forming method: The industry’s leading roll forming technique is used, with accurate mold design and stringent process control, to guarantee that each purlin has exceptionally high forming accuracy and stability. This technique not only improves the overall product quality, but it also significantly increases the bearing capacity and service life of the purlin.

- Highly automated, simplified operation, and increased efficiency: Equipped with a fully automatic control system, it achieves complete automation from raw material input to final product output. This design not only dramatically decreases the complexity of operation, making it simple for even novices to get started, but it also significantly enhances production efficiency, resulting in increased value for consumers.

Heavy Duty Purlin Machine Specifications and characteristics

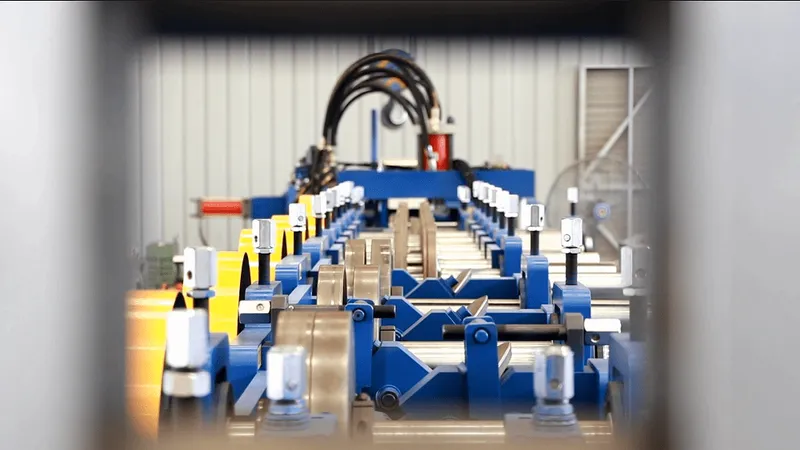

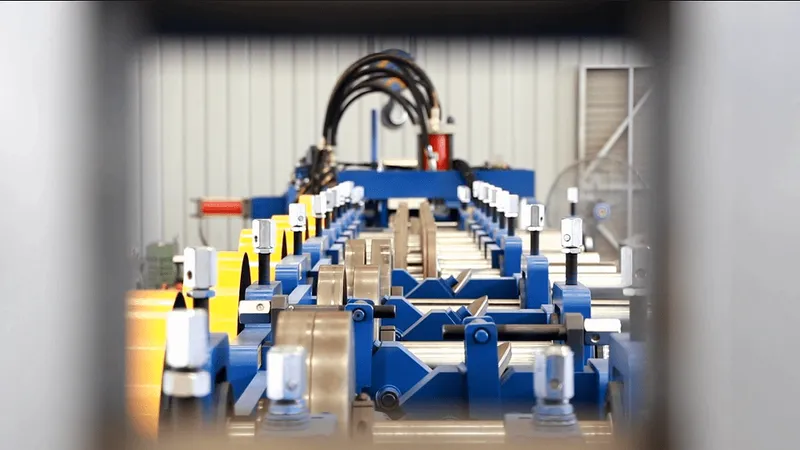

1. Machinery makeup

The major elements of CZ purlin machine are:

- The gearbox drive system stabilizes and efficiently drives the machine.

- Uncoiler feeding and leveling device: Smoothly and correctly feeds raw materials like strip steel to the next step.

- Punching system: Punch automatically per parameters.

- Pre-cutting system: Cut raw materials to varied lengths before shaping.

- Roller forming system: Rollers precisely press raw materials into C- or Z-shaped purlins.

- Hydraulic post-cutting system: Purlins are precisely cut after shaping.

- Output table: Easy purlin product collection.

- Hydraulic station powers hydraulics.

- The PLC (control system) is the brain of the machine, commanding each portion to follow the program.

2. Special functions

- Linear guide assembly: The machine can seamlessly adjust web size using linear guide assembly technology, assuring product precision and stability.

- High yield strength product production: The machine can create standard products with 550Mpa yield strength for high-strength and high-demand applications.

- lengthy manufacturing line: A lengthy production line ensures product uniformity and stability.

- No apertures in the finished product: The precision roll forming technology ensures no openings, improving product quality and dependability.

- C/Z interchange has 3 steps: Switching between C- and Z-type purlins is easy, increasing manufacturing flexibility.

Automatic size change: This saves time and improves production efficiency.

3. Advantages

- The PLC control system allows one-button operation, simplifying operation.

- High-quality components and modern production methods assure machine stability.

- Precision: High-quality components and precise control systems ensure product correctness and consistency.

- It supports walls and roofs of factories, warehouses, and other buildings, and has wide application potential.

Machine Components

1.Hydraulic Decoiler

De-coiler Type: automatic fasten and loosen

Weight capacity: 6T

2.Feeding and Leveling Device

Feeding and Leveling Device: It is used for making the material flat before feeding into the roll forming machine.

3.Hydraulic Pre-Cutting & Punching device

Pre-cutting used to cut raw materials before roll forming.

Punch on flat sheet. PLC control punch quantity and horizontal position; vertical position adjust by manual.

Web punching quantity& size: as per customer’s requirement.

Flange punching quantity&size: as per customer’s requirement.

Punching bar and punching die can be changed easily.

4.Main machine

Driven type: By gear boxes

Speed of forming: 0-30m/min

Roller : About 21 groups rollers

Roller Material is Cr12 mould steel:

Diameter of down roller is around 360mm

Shaft: Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product, Diameter of main shaft ф95

Material of main shaft: 40Cr

5.Post Hydraulic Cutting Device

Adopt our innovative cutting system, CZ integrated & adjustable cutting mold do not need to replace cutting mold when purlin sizes change

Application Effect