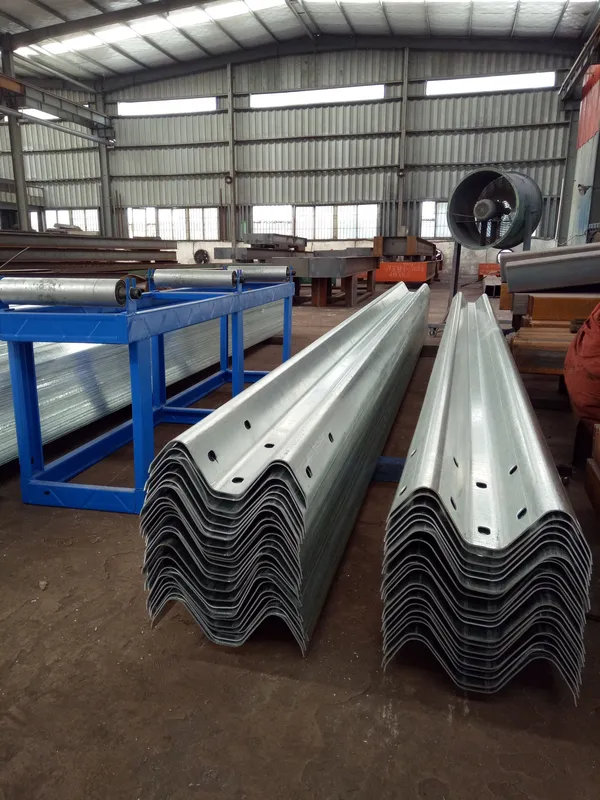

Top-selling hot-dip galvanized steel W-beam highway guardrail roll making equipment. This equipment is essential for highway building because to its great performance and manufacturing capacity. We use high-quality materials and innovative manufacturing technologies to make our W-beam guardrail roll forming machine stable and durable. Its precision rolling mechanism rolls hot-dip galvanized steel plates into conventional W-beam guardrails swiftly and precisely, enhancing manufacturing efficiency and quality.

We understand the value of after-sales service. To guarantee clients get fast and expert assistance throughout usage, we provide comprehensive after-sales service. We will provide clients the finest service throughout equipment installation, commissioning, and post-maintenance.

Quality goods and excellent after-sales service are guaranteed with our hot-dip galvanized steel W-beam highway guardrail roll forming equipment. We provide top-notch solutions to help you succeed in highway building.

Flow chart of guide roll forming machine

The Guide Roll Forming Machine is a professional equipment that processes materials such as hot-dip galvanized steel sheet into high-quality W-beam highway guardrail through precise rolling technology. With its high quality, high efficiency and perfect after-sales service, this machine has become a preferred tool in the field of highway construction.

Six features of highway guardrail molding machine

- Roll Forming Technology: Highway guardrail molding machine uses roll forming technology to effectively press guardrail material into shape via accurate roller rotation and pressure. This technique provides product form precision and consistency.

- The molding machine produces guardrails rapidly and efficiently. The manufacturing cycle is considerably shortened, efficiency is increased, and expenses are reduced.

- Energy saving and environmental protection: the highway guardrail molding machine employs sophisticated energy-saving technology and eco-friendly materials to decrease pollution. It also saves energy and cuts usage.

- The highway guardrail molding machine uses roll forming technology to assure exact size, uniform shape, and steady and dependable product quality. The items fulfill highway guardrail production standards and may be used well.

- Simple operation: the molding machine’s interface and procedure are simple. Workers can rapidly grasp the operating technique, reducing difficulties and improving efficiency.

- Simple maintenance: highway guardrail manufacturing machines are easy to clean and maintain. This minimizes equipment maintenance costs and extends its lifespan. Additionally, the equipment’s control system is simple, easy to troubleshoot, and repair.

Component of roll forming machine

1) Feeding

2) Rollers of Machine

3) Forming cutter

4)PLC Control system (2 type for choosing)

Easy to operate

5)Decoiler (2 type for choosing)

1. Manual decoiler 2. Hydraulic decoiler

Why choose our company’s highway guardrail forming machine

- Years of research and development and manufacture of highway guardrail forming equipment have given our firm extensive knowledge. Our items are roll-formed using modern technology. By accurately managing roller rotation and pressure, we can create guardrail materials to fulfill highway guardrail production standards.

- Our highway guardrail manufacturing equipment is energy-efficient and environmentally friendly. Technological innovation and green manufacturing are our priorities. By improving design and using new materials, equipment is more efficient, energy consumption is lower, and pollution is reduced. This follows contemporary production trends and helps clients economically.

- Highway guardrail forming equipment at our firm rigorously supervises product quality. By employing high-quality materials and components and tight manufacturing methods and quality control, we assure each equipment meets high quality standards. This gives our goods stability and reliability, earning consumer confidence and respect.

- Experience and after-sales service are our priorities. We provide complete technical support and solutions to guarantee clients get prompt and competent assistance. Our after-sales support staff is knowledgeable and qualified and can swiftly fix client difficulties, easing their concerns.

- Our highway guardrail manufacturing equipment is straightforward to use and maintain. We emphasis on humanized equipment design, making the operating interface clear and easy to grasp so workers can rapidly learn it. The equipment is easy to maintain, reducing client maintenance costs and time.