Metal Deck forming machine has become an indispensable machine in the construction industry due to its high efficiency and customization.

The innovative roll forming technology used by the metal deck forming machine allows it to process steel plates fast and correctly into metal decks with a variety of forms and requirements. The manufacturing efficiency of metal decks has been significantly enhanced and production costs have decreased due to its high-precision and high-efficiency processing capabilities.

Our metal deck forming machine may be highly customized. We are aware that every client has different needs, thus we can customize steel deck roll forming machines to meet their demands. We can satisfy the specific requirements of clients about the dimensions, weight, and form of the deck as well as the precision and speed of the production.

Function:

- Customized production: In addition to producing a number of metal deck specifications in accordance with industry standards, our metal deck forming machine may be adjusted to suit the unique demands of our clients, guaranteeing that the final product satisfies their use requirements.

Production efficiency: The machinery has a high production capacity and uses cutting-edge roll forming technology. With a maximum production speed of 20 meters per minute, it greatly increases manufacturing efficiency.

Features:

- Modular design: The equipment has a modular design, which increases the degree of commonality between different components and facilitates quick and easy part replacement and maintenance.

- Manufacturing capability for thick plates: Our metal deck forming machine can produce thicker plates to satisfy the load-bearing needs of various projects by optimizing the main machine structure and maintaining tight quality control.

- High-precision processing: The equipment frame is processed entirely in a single step, and a strong machine tool guarantees that every matching dimension and position is accurate. As a result, there is less need to troubleshoot the forming unit, which saves labor costs.

- Automatic program control: Thanks to the equipment’s sophisticated automatic program control technology, parameter setup is very automated and straightforward. The control system uses premium brands and has a strong self-learning impact to guarantee the equipment’s stability and dependability.

- Humanized operation interface: This equipment’s pleasant and user-friendly human-machine interface makes operations more straightforward and practical.

Xiamen Aoyu is dedicated to offering consumers worldwide top-notch and effective metal deck forming equipment. For further information about our steel deck floor forming machines, we invite both domestic and international clients to get in touch with us. We look forward to building a solid and long-lasting working relationship with you.

Profiles of Floor decking machine

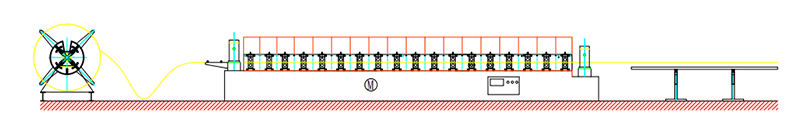

Work Flow

Decoiler→Feeding Guide Device→Pre-Cutting Device(optional)→Roll Forming System→Hydraulic Post Cutting Device→Exit Rack

The metal deck forming machine’s composition

A number of essential components make up the metal deck forming machine, which guarantees precise and effective manufacture of metal decks of the highest caliber. The machine’s primary parts and attributes are as follows:

1. Feeding system

To maintain the manufacturing process’ continuity, the feeding system is in charge of smoothly and constantly feeding the steel coils into the forming area.

2. Hydraulic pre-cutting knife

The hydraulic pre-cutting knife offers robust assistance for the length management of the steel plate prior to shaping by using hydraulic power to accomplish quick and accurate shearing operations.

3. Floor deck machine roller

The superior bearing steel GCr15 used in the construction of the roller is carefully machined and heat-treated using a CNC lathe. The roller’s surface is hard chrome-plated to guarantee its high strength, resistance to wear, and extended lifespan. The steel plate’s accuracy and stability throughout the transmission process are guaranteed by the design of the guide rails used in belt feeding. The frame has a good load-bearing capability and is constructed from 300#H-shaped steel that has been welded.

4. Forming knife

The floor deck machine’s forming knife is constructed of premium mold steel Cr12, which has been heat-treated to guarantee the knife’s hardness and wear resistance in order to satisfy long-term and effective production requirements.

5. PLC control system

Automatic equipment operation is made possible by PLC control systems, which are simple to use and intuitive to learn. With its capacity for self-learning, the system may automatically modify settings in accordance with production requirements, therefore enhancing both production efficiency and product quality.

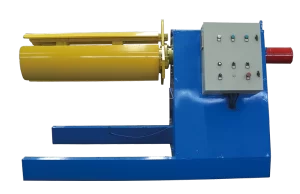

6. Uncoiler

External power is not needed for the hand uncoiler. It is practical and handy as it can be manually controlled to contract and stop the steel coil’s inner hole. Stronger power and stability allow the 5-ton hydraulic uncoiler (optional car or no car) to handle higher numbers and larger sizes of steel coils. The coil’s inner diameter range is 480mm±30mm, its maximum feed width is 1250mm, and its maximum capacity is 5 tons.

About our company

Our skilled technical staff and cutting-edge production equipment enable us to develop and produce a wide range of conventional and custom metal deck forming machines. Since we understand how important metal decks are to the construction sector, we strive for perfection all the time to guarantee that every item of equipment we supply is of the highest quality.

Customized service

We provide specialized services since we understand that every client has different demands. We may tailor the equipment to the unique needs and expectations of the client, regardless of the features, functions, or look, to guarantee that the equipment completely satisfies their expectations.

Efficient production

Our manufacturing machinery uses cutting-edge procedures and technology to produce goods in an effective and reliable manner. Our production team’s vast expertise and exceptional abilities enable them to guarantee the equipment’s effectiveness and quality throughout the manufacturing process.

Strict quality control

We focus on the quality of our products and maintain stringent quality control across the whole supply chain, from the acquisition of raw materials to manufacture, assembly, commissioning, etc. To make sure that every piece of equipment satisfies both client demands and national standards, we use cutting-edge testing tools and equipment.

Perfect after-sales service

We provide flawless post-purchase assistance, encompassing equipment setup, commissioning, instruction, upkeep, and more. With their extensive knowledge and expertise, our after-sales support staff can quickly resolve issues that arise from consumers using the equipment, ensuring that it continues to function normally.