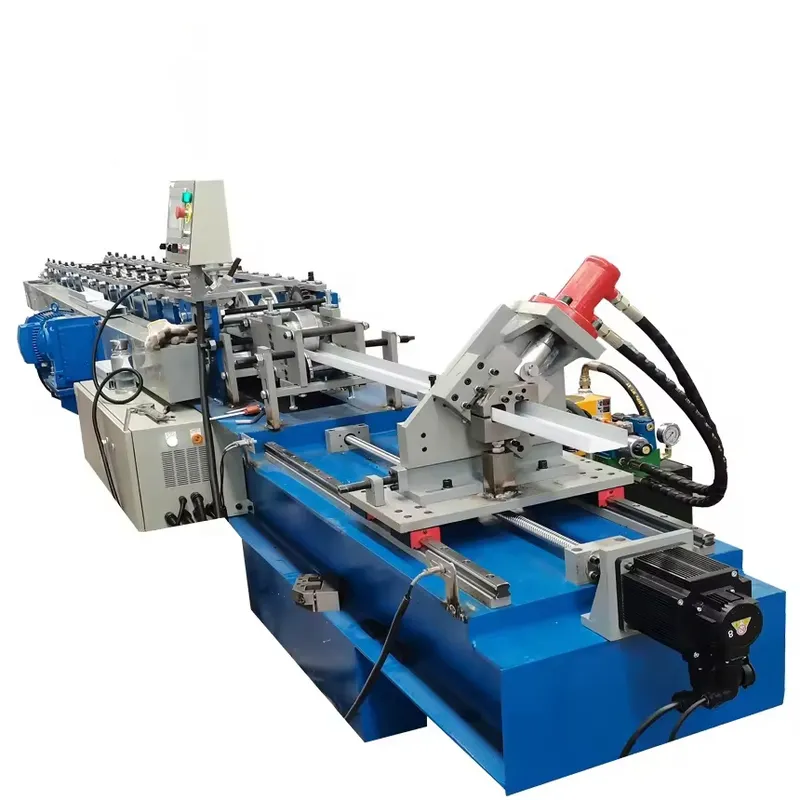

The C75-200 multi light steel frame Machine is a powerful processing equipment designed for processing steel profiles of various specifications. It can easily process steel profiles from 3 inches (75 mm) to 8 inches (200 mm), showing extremely high processing flexibility and wide applicability. A highlight of this machine is its convenient punching tool switching function. Users can quickly adjust production parameters to produce steel profiles of different diameters by simply switching between different punching tools. This feature greatly improves production efficiency, making the C75-200multi lgs machine an indispensable and efficient tool in the field of metal processing. Whether it is small-scale customized production or large-scale batch production, the machine can meet the diverse needs of customers with excellent performance and stable processing quality.

Multi Light Steel Frame Machine Application Features

In the construction industry, the C75-200 light steel keel machine has become a valuable special machinery and equipment with its excellent performance and wide application fields. This machine can not only process steel profiles in the range of 3 to 8 inches (75-200 mm), but also flexibly produce steel profiles of different diameters by simply switching the punching tool, meeting diverse processing needs.

The light steel keels produced by the C75-200 light steel keel machine are widely used in the construction field. They are widely used to construct light commercial buildings with movable and modular structures, such as walls, floors and roofs, providing solid structural support for these buildings. At the same time, these light steel keels are also fully capable of meeting all structural requirements of one to six-story residential buildings, providing reliable basic materials for residential construction.

Technical Parameters

| Model | C75-200 |

| Web Size | 75-200mm |

| Profile Height | 41mm |

| Profile Lip | 10-15mm |

| Strip Width | 165-346mm |

| Material Thickness | 0.75-1.6mm |

| Gauge Adjustment | Full Automatic Servo Powered |

| Roll Forming Stations | 17 |

| Comprehensive production speed | 8-15m/min |

| Production Speed(without punching and cutting) | 35m/min |

| Typical Production Output for drywall panel |

600m/h |

| Typical Production Output for roof truss and floor joist |

480m/h |

| Production Speed(without punching and cutting) |

2100m/h |

| Servo Motor(Brand: Inovance) | 14kw |

| Hydraulic System (Brand: Japan YUKEN) |

11kw |

| PLC (Brand: Japan Panasonic) | Panasonic |

| Power Voltage | 380V/50Hz/3Phase(can be configured as required) |

| Hydraulic Cooling | Yes |

| Machine Size(mm) | 8300x1600x1960 |

| Net Weight | 10T |

| Jet Printer | Standard |

| Design Software | Vertex BD |

| De-coiler Capacity | 3T,Powered |

| Punch/Cutting Accuracy | ±1mm/0.75mm |

Application

Advantages

- Precise positioning: The C75-200 light steel keel machine can complete positioning automatically and accurately during processing, reducing mistakes caused by human operation faults. This maintains the precision and integrity of the wall keel.

Strong environmental adaptability: The equipment is unaffected by weather and environmental influences, allowing for correct processing in any environment to assure product quality. - Simple operation: The C75-200 light steel keel machine is straightforward to use. Simply switch on the electricity, change the processing parameters, and push the button to finish the procedure. This decreases the operator’s technical needs and increases production efficiency.

- High production efficiency: Thanks to its accurate placement and easy operation, the C75-200 light steel keel machine can manufacture a high number of wall keels in less time. Compared to typical manual processing techniques, the technology may dramatically reduce processing time and increase production efficiency.

- Smooth operation: The C75-200 light steel keel machine uses a high-precision mechanical transmission system with an electronic control system, resulting in low noise and smooth operation that is not prone to failure.

- Low material loss rate: The equipment prevents material movement during cutting, maintaining precision and quality, and therefore lowering material loss.

- Perfect safety protection measures: The C75-200 light steel keel machine includes a number of safety features, including overload protection, emergency stop protection, and early warning prompts, which can effectively protect the operator’s personal safety as well as the safety of equipment and facilities.

Features

- Versatility: The C75-200 light steel keel machine is a cold bending machine with several functionalities. It may produce keels with various specifications and forms to fulfill the demands of various businesses.

- tiny space occupation: The equipment is tiny in size, occupies little space, is portable, and ideal for a variety of industrial scenarios.

- High hardness: The molds for the C75-200 light steel keel machine are made of specific materials that are highly hard and wear resistant, allowing them to be utilized for an extended period of time without distortion.

- Long service life: By replacing outdated components in a timely manner, the C75-200 light steel keel machine can maintain long-term stability and prolong its service life.