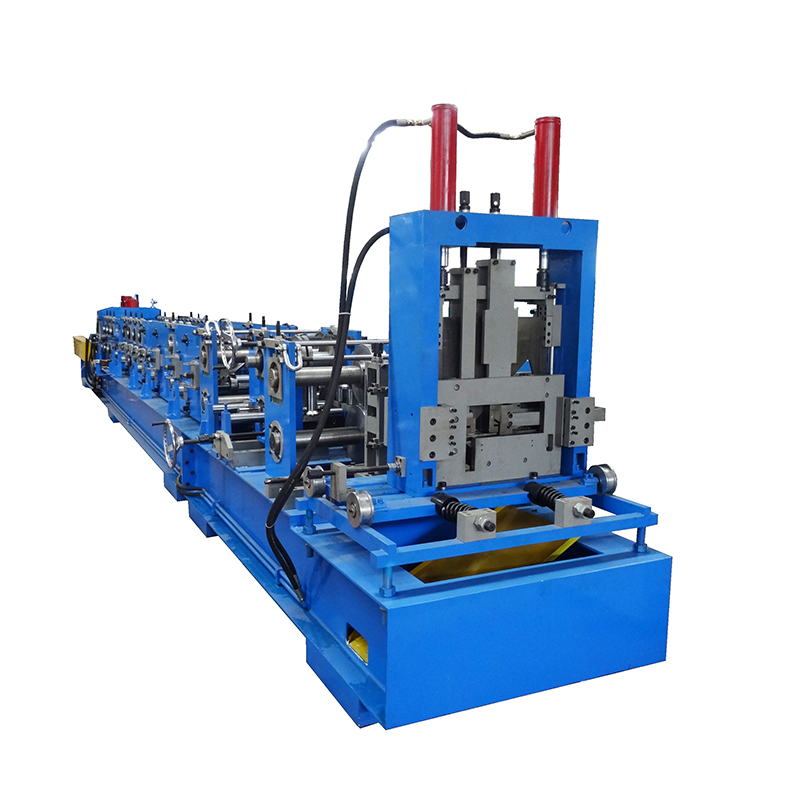

Standing seam roofing machine. This portable device guarantees the waterproof effect of the roof and significantly increases construction efficiency by processing the double standing seam panels needed for standing seam roof installation.

Product Features

- Processing double standing seam panels quickly and precisely with the standing seam roofing machine saves time and labor compared to conventional processing techniques.

- High accuracy: Every roof panel’s size and angle are guaranteed to meet the strictest requirements by the application of cutting-edge control systems.

- Easy use: Non-experts can get started with the equipment very fast because it is humanized and simple to use.

- Excellent waterproof effect: The equipment processes the precise seams to produce an excellent waterproof effect that successfully stops rainwater leaks. The double standing seam roof panels are installed by overlapping.

- Strong durability: Constructed from premium materials and fine workmanship, it guarantees the equipment’s ability to function steadily in demanding construction settings and prolong its useful life.

Functions and application

- Let’s discuss about feeding the metal through the rollers to acquire the final shape. A single hand wheel turn allows for a smooth adjustment of the breadth from 220 mm to 530 mm. The shaping rollers align with the hand wheel’s revolution.

- The rollers are the nicest feature of this contraption. In addition to gauging rollers, which help achieve the desired stiffness or thickness, semi-round or trapezoidal rib rollers can be fitted. Furthermore, the composite rollers provide no risk of damaging the polymer coating. At one of the final phases, the panel travels through the final straightening station before being sliced at each individual length with a shear or guillotine.

- This portable roll forming machine for standing seam roofing comes complete with all processing equipment. consists essentially of the electric control cabinet, the main forming machine, the coiler, and any other relevant attachments. A standing seam roll forming machine produces roof panels with concealed fixings or fasteners. Every cap and trim is designed to ensure a weatherproof roof that is integrated. The most common type of standing seam roll forming machine is one that hides the joints or fasterners.

Advantages of portable standing seam machines

- Portability: Carrying and moving the equipment is made simple by its small size and lightweight.To adjust to different construction environments, it is easily transportable between different venues and sites.

- Efficiency: By precisely and swiftly processing double standing seam panels, the standing seam machine significantly increases construction efficiency.

It can save a great deal of time and labour costs when compared to conventional manual or semi-automatic processing techniques. - High precision: Every roof panel’s size and angle are guaranteed to satisfy high precision standards by the application of sophisticated control systems and cutting technology.Waterproof performance can be enhanced and tight joints between roof panels can be guaranteed by high-precision processing.

- Easy operation: The humanization of the equipment design and the clear and understandable operation interface. Worker without prior professional experience can start working right away.It raises construction efficiency and shortens operator training time and expense.

- Excellent waterproof effect can be guaranteed by the exact seams processed by the equipment because of the overlapping installation design of double standing seam roof panels.Rainwater leaks should be effectively avoided, and building service life and safety should be increased.

- Excellent workmanship and premium materials allow the equipment to function steadily even in demanding construction settings.

The robust construction lowers both the expense of later maintenance and the frequency of equipment replacement and repair. - High adaptability: Fits requirements for processing roof panels of various thicknesses, sizes, and materials.

For different projects, it can be modified and set up in accordance with particular building specifications. - Excellent safety performance: Operator personal safety can be successfully protected during operation by the equipment design, which satisfies safety regulations.

lowers the possibility of safety mishaps brought on by wrong use or malfunctioning equipment.

Why is the machine portable?

The machine’s portability to the job site is attributable to more than just its size and weight. Furthermore, the overall design emphasizes harsh road conditions and trouble-free transportation. The profiling device can be easily detached from the frame.