High-quality automated conversion. The CZ purlin machine for sale uses modern automation technology, allowing for the quick manufacturing of C-type and Z-type purlins. Its precision control system maintains the accuracy and stability of each manufacturing link, resulting in high-quality final products. Whether the necessity is for dimensional precision or the pursuit of form regularity, this equipment can readily handle both and fulfill the different requirements of clients.

In terms of revolutionary design, the high-quality automated conversion CZ purlin forming machine strikes the ideal balance between production efficiency and ease. The equipment operates more smoothly and easily when the structural layout and operating method are optimized. At the same time, the equipment has a sophisticated fault detection and alarm system that can identify and address possible issues in real time, ensuring production continuity and stability.

In addition, the high-quality automated conversion CZ purlin forming machine is very adaptable. It can swiftly alter production settings and mold configuration to satisfy various construction demands and design requirements, resulting in purlin products that meet client specifications. This flexibility not only increases equipment usage, but also offers consumers with a more customized service experience.

Specification of CZ Purlin Machine

If the CZ purlin machine production line occurs, the system will automatically issue alert, which will greatly improve the security of the process. At the same time, the driver system of this device has also been improved. Installing variable frequency control can make the products in the production line more accurate positioning, control the production speed and specifications of the bars to meet the requirements of different accuracy.

Therefore, the CZ purlin machine has a wide range of application prospects in the construction industry, especially in terms of the main force structure of large and medium-sized industrial civil buildings, its efficient and economic characteristics make it an ideal choice. For more information about the CZ integrated bar machine, it is recommended to consult a professional mechanical engineer or consult relevant literature.

Significant benefits of high-quality automated changeover CZ purlin forming machine.

- The automated switching function increases efficiency: This is a standout feature of the equipment. It can complete the conversion rapidly when changing the purlin type without the need for user intervention, saving both time and money. This function smoothes the manufacturing process and considerably enhances production efficiency, making it ideal for production situations with frequent product type changes.

- Easy to operate and use: The equipment has an innovative control system that simplifies and intuitively operates the process. Users may easily grasp the equipment’s operating manner without requiring extensive training, reducing operational difficulties and increasing job productivity. At the same time, the system’s intelligent design lowers the risk of human mistakes, assuring production stability and safety.

- High cost performance and long-term returns: Although the high-quality automated changeover CZ purlin forming machine requires a relatively large initial investment, its long-term efficiency and stability will provide considerable economic advantages to clients. The effective functioning of the equipment lowers manufacturing costs while improving product quality, resulting in increased market share and profitability for clients. In the long term, it is a good investment.

- Strict quality control to assure quality: Every product that leaves the manufacturer has undergone rigorous quality control and testing to ensure that it meets the highest standards of performance, accuracy, and durability. This unwavering commitment to quality has won our equipment a positive market reputation and made it a reliable option for clients.

Tech features

- manufacturing efficiency: The machine’s powerful automated control system can properly regulate the whole manufacturing process, from raw material input to completed product output, in one go.

- The machine’s accurate roll-forming mechanism ensures purlin forming accuracy, giving the product great dimensional stability and flatness.

- Automatic changeover: This machine’s automatic changeover is unique. Simple procedures to changeover between C- and Z-type purlins without changing components boost manufacturing flexibility.

- To guarantee long-term functioning, the machine is made of high-strength, corrosion-resistant materials.

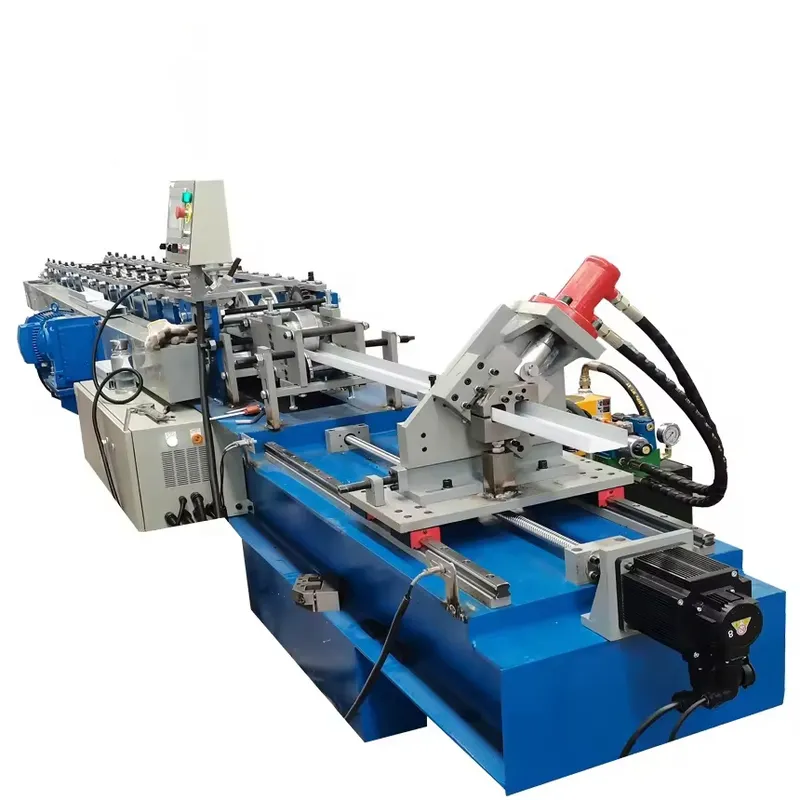

Machine Components

1.Feeding and Leveling Device

Side wall thickness: Q235 t25mm;Tie rod:ф20

Shafts manufactured from 45#steel,

Diameter=φ115mm,Tone plated with hard chrome Coated, precision machined

2.Hydraulic Pre-Cutting & Punching device

Pre-punching and pre-cutting device share the hydraulic system

Hydraulic motor:7.5kw,

Hydraulic pressure :16Mpa

Punching and Cutting tool material:mold steel Cr12MoV

3-cylinders hole punching system for punching holes on web and flange

3.Main machine

Shafts Diameter=ф95, precision machined

Gear/Sprocket driving

Main Servo Motor =30kW

Speed redcucer motor:K series;

Size changing motor:6pcs,

Automatically controlled by computer system

Sliding block: 150 * 150mm

4.Post Hydraulic Cutting Device

Post to cut, stop to cut

One cutter could cut all forming sizes

5.PLC Computer Control System

Cut-to-Length Tolerance≤±1 mm

Control Voltage: 24V

Application areas

High-quality autochange Many engineering industries, including building, bridges, and tunnels, employ CZ purlin forming machines. Its C- and Z-type purlins are strong and durable, suitable for complicated applications.