For the purpose of producing C- and Z-type purlins, a powerful and versatile cold-bending forming tool is the heavy-duty automated CZ purlin roll rolling machine. It combines sophisticated cold-bending forming technology with an automated control system and high-precision processing technology, giving users the flexibility to select the right purlin production equipment according on their individual requirements. You may locate an appropriate equipment solution for every kind of project, be it a large-scale engineering project or a small or medium-sized business.

Features of the Product

- Efficient production: C-type and Z-type purlins may be formed and cut more rapidly thanks to an efficient forming procedure and a high-speed transmission system.

To satisfy the demands of large-scale projects, the equipment can produce a huge number of purlins quickly, depending on various models and configurations. - High-precision processing: Utilizing sophisticated control systems and precise forming molds, this method guarantees that the purlins maintain their stable shape and precise dimension.

- The equipment is capable of producing C-type and Z-type purlins that satisfy different engineering specifications thanks to high-precision processing technology.

- Simple to use: The equipment’s user interface is straightforward to use and pleasant. Simple actions allow users to achieve purlin manufacturing and changeover.

- Its sophisticated control system allows it to keep an eye on production data and equipment status in real time, giving users an easy way to manage their equipment.

- High adaptability: The machinery may be modified to fulfill the demands of many engineering projects by producing purlins with varying sizes and specifications.

- It is simple to achieve the switching production of C-type and Z-type purlins by modifying the molding mold and control system settings.

- Sturdy construction, premium components, and cutting-edge production techniques guarantee that the equipment will continue to operate steadily and dependably even after extended periods of continuous usage.

- With a comprehensive protective system, it can successfully stop overload, overheating, and other factors that might cause equipment damage and failure.

Details of the CZ Purlin Machine

With their exceptional load-bearing capacity and stability, heavy-duty CZ purlins are an essential component of steel structures and are often used in the building industry.

The “C”-shaped cross-section of C-shaped purlins is typically formed from hot-rolled steel strips. They can successfully sustain buildings because of their tremendous strength and rigidity. The Z-shaped purlin is formed of a thicker steel strip and has a cross-sectional shape that resembles the letter “Z”. It is appropriate for large-span constructions and has superior bending resistance and load-bearing capability.

In the construction industry, heavy-duty CZ purlins are often deployed, particularly in large-span, high-weight structures like stadiums, warehouses, and industrial facilities where their exceptional stability and load-bearing capabilities are fully exploited. Additionally, it may successfully lessen structure damage and has strong earthquake resistance.

Heavy-duty automatic CZ purlin plate rolling machine main parts description

Hydraulic uncoiler

Uncoiler type: designed with automatic tightening and loosening functions, convenient for fast loading and unloading of materials.

Weight capacity: capable of carrying up to 10 tons of coils, meeting the needs of large-scale production.

Feeding and leveling device

Function: before the material is fed into the roll forming machine, ensure that the surface of the material is flat and wrinkle-free, providing high-quality raw material state for subsequent forming processing.

Hydraulic pre-cutting and punching device

Pre-cutting function: precise cutting of raw materials before roll forming.

Punching function: Punching operation is performed on flat materials, the position and number of punching holes are accurately controlled by PLC, the horizontal position is automatically adjusted, and the vertical position can be manually fine-tuned.

Customization: The number and size of punching holes on the web and flange can be customized according to the specific requirements of customers.

Convenience: The punching rod and punching die are designed to be easy to replace to meet different production needs.

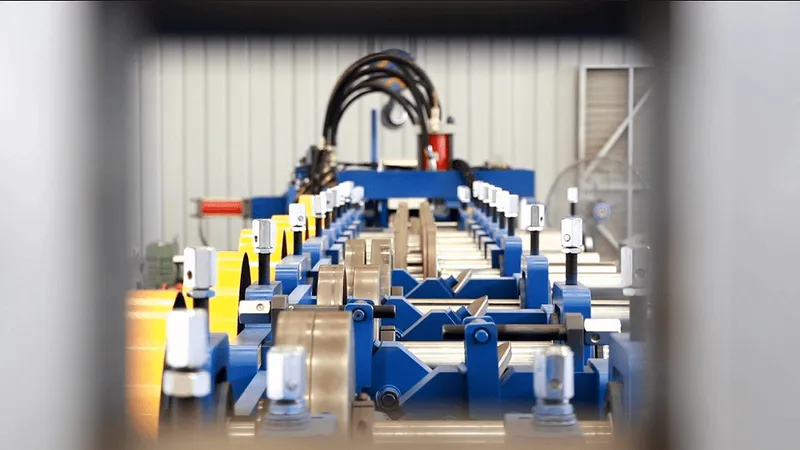

Main machine

Drive mode: Adopt efficient gearbox drive to ensure the stability and efficiency of transmission.

Forming speed: adjustable range is 0-30 m/min, flexible to adapt to different production rhythms.

Roller configuration: about 24 sets of rollers, made of Cr12 mold steel, to ensure the accuracy and durability of forming.

Lower roller diameter: about 360 mm, providing sufficient pressure and contact area to ensure the quality of forming.

Roller shaft processing: after two grinder processing, to ensure the accuracy and durability of the shaft, thereby ensuring the accuracy of the finished product.

Spindle material: 40Cr material is used, which has both strength and toughness to meet the needs of long-term high-intensity work.

Rear hydraulic cutting device

Innovative cutting system: the company’s innovative cutting technology is used to ensure the accuracy and efficiency of cutting.

CZ integrated adjustable cutting mold: the unique design makes it unnecessary to replace the cutting mold when the purlin size changes, greatly improving the flexibility and efficiency of production. This design not only reduces the time for changing the mold, but also reduces the production cost, while ensuring the consistency and quality of cutting.

Application

The coiling and cutting of metal products, including steel, aluminum, copper, and stainless steel, is a significant function of plate rolling machines in the metal processing industry.

- In order to create materials with bigger coil diameters for further processing, it may roll up metal sheets or wires. For instance, steel mills roll the generated steel coils into easy-to-transport and store bundles using plate rolling machines.

- Construction sector: A variety of metal building materials, including barrel tiles, wall panels, roof panels, and awnings, are produced using plate rolling machines for the construction industry.

- By modifying the settings of the equipment and the molds, metal sheets may be rolled into precise forms to suit the unique requirements of building projects.

Plate rolling machine technology has advanced along with the construction industry, enabling automated processing, increasing production efficiency, and guaranteeing the quality and beauty of building materials.

automotive manufacturing industry: A significant amount of metal components must be made and kept in storage as rolled plates throughout the automotive manufacturing process. - The plate rolling machine is capable of swiftly and effectively rolling metal sheets to the desired width and thickness, giving the construction of car bodies, doors, windows, and other components a solid foundation.

- The purlins used in car manufacture are precise in size and stable in form thanks to high-precision processing technology, which satisfies the demanding requirements of automotive design.

- packing sector: Cans and packing boxes are among the containers produced in this sector using plate rolling machines.

- By rolling metal sheets into a cylindrical form and then shaping them using cutting, folding, and other techniques, packing materials may be produced more efficiently and with a higher utilization rate.

Technical features and advantages

- Heavy-duty automatic CZ purlin rolling machines are usually equipped with high-precision forming molds and advanced control systems to ensure that the purlins are accurate in size and stable in shape.

- By lowering the complexity and labor intensity of manual operation, the implementation of an automated control system increases production efficiency.

- The machinery is capable of meeting the demands of continuous, long-term manufacturing and has a robust construction and steady, dependable operation.

- Its sophisticated management system allows it to track production data and equipment condition in real time, giving users an easy way to manage their equipment.

- Customized service: To satisfy the requirements of purlin size, form, and material for various engineering projects, the heavy-duty automated CZ purlin rolling machine may be tailored to the particular demands of clients.

- Assure that the equipment can operate steadily and optimally while in use by offering expert technical support and after-sales service.