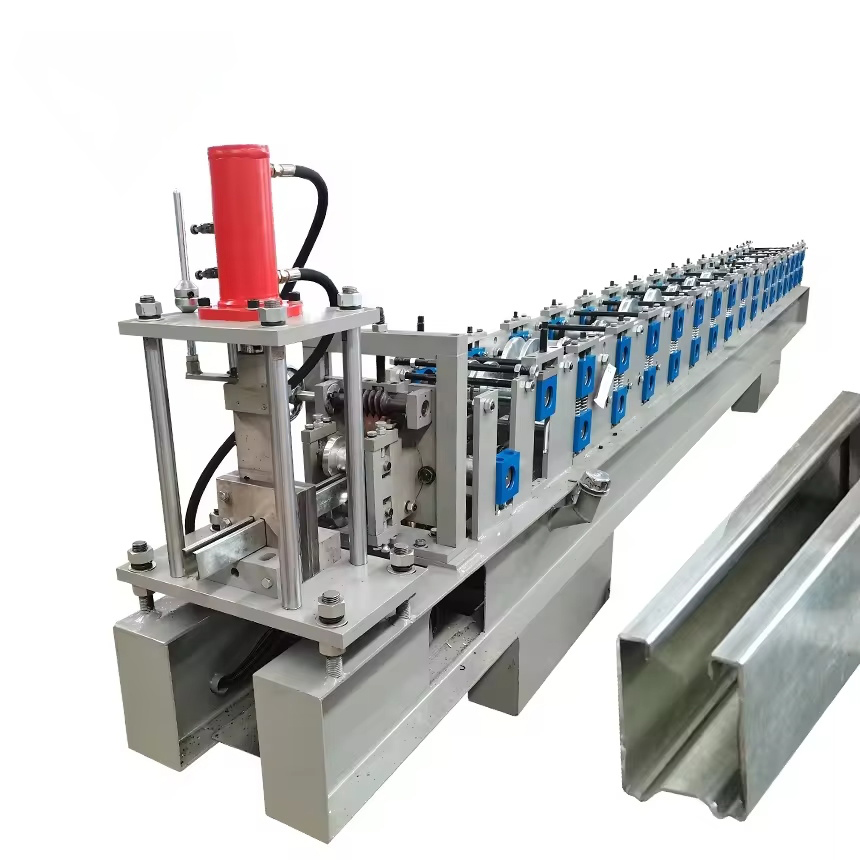

Key Parameters of the Rollextech Lightweight Steel Framing Machines

- Material Selection: The machine utilizes high-quality galvanized sheets as its raw material, with a thickness range of 0.75mm to 1.2mm and a tensile strength of up to 550 MPa. This material choice not only imparts excellent corrosion resistance but also ensures adequate structural strength, making it suitable for a wide range of construction and structural applications to meet diverse usage demands.

- Customizable Product Dimensions: The machine can produce two main sizes of C-shaped steel structures: 89x41x10mm and 140x41x10mm. Additionally, these dimensions can be flexibly adjusted according to the user’s actual requirements, allowing for precise matching of different architectural project designs and enabling personalized customization.

- Outstanding Production Efficiency: The machine boasts a maximum production speed of up to 48 meters per minute (excluding cutting and punching time), positioning it as a leader among similar devices. Such high production efficiency enables the Rollextech lightweight steel structure frame machine to swiftly complete large-scale production tasks, effectively shortening construction timelines and enhancing overall production efficiency.

Profile:

Construction projects:

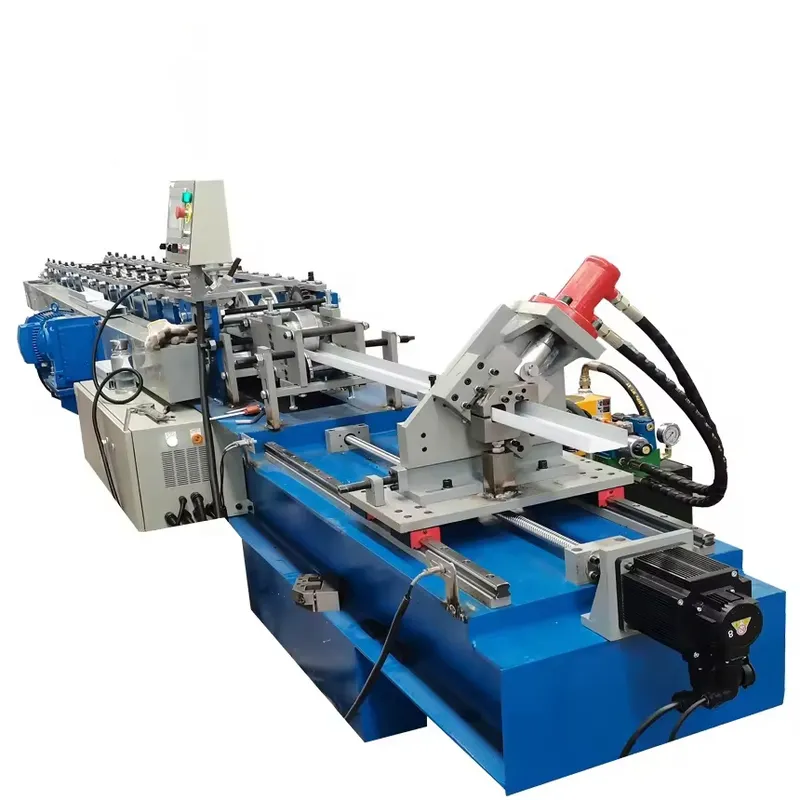

Rollextech Lightweight Steel Frame Machine features

The Rollextech lightweight steel frame machine has gained widespread recognition in the construction and structural application fields due to its outstanding performance and diverse functionality. Here are the key features of this machine:

High Automation

The Rollextech lightweight steel frame machine integrates advanced control software to achieve full automation from data input to product formation. This feature minimizes manual intervention, enhancing production precision and consistency while significantly increasing overall efficiency. Users only need to input the required parameters, allowing the machine to autonomously complete production tasks, which greatly reduces operational difficulty and time costs.

Strong Adaptability

This machine exhibits exceptional flexibility and adjustability, easily accommodating various specifications and shapes for lightweight steel frame production. Users can flexibly adjust machine parameters according to actual design and production requirements, enabling rapid production of compliant lightweight steel frames. This adaptability allows the Rollextech lightweight steel frame machine to be widely utilized in various construction and structural fields, meeting diverse usage demands.

Environmentally Friendly and Energy-Efficient

The Rollextech lightweight steel frame machine employs advanced production processes and materials aimed at reducing energy consumption and emissions. During production, the machine efficiently utilizes raw materials, minimizing waste and pollution, in line with modern green building concepts. Additionally, the machine operates with low noise levels, reducing environmental impact and creating a more comfortable production environment for users.

Easy Maintenance

Designed with a compact structure and rational layout, the Rollextech lightweight steel frame machine simplifies maintenance and upkeep tasks. Users can ensure a long-term stable operation with just regular inspections and cleaning. Moreover, the machine’s components are easy to replace and repair, lowering operational costs and extending the equipment’s lifespan.

Technical Parameters

| Model | C89 |

| Web Size | 89mm |

| Profile Height | 41mm |

| Profile Lip | 7-12mm |

| Strip Width | 178-182mm |

| Material Thickness | 0.75-1.2mm |

| Gauge Adjustment | Full Automatic Servo Powered |

| Roll Forming Stations | 13 |

| Comprehensive production speed | 8-15m/min |

| Production Speed(without punching and cutting) | 48m/min |

| Typical Production Output for drywall panel |

750m/h |

| Typical Production Output for roof truss and floor joist |

550m/h |

| Production Speed(without punching and cutting) |

2880m/h |

| drywall panel | 7.5kw Servo Motor |

| Hydraulic System (Brand: Japan YUKEN) |

7.5kw |

| PLC (Brand: Japan Panasonic) | Panasonic |

| Power Voltage | 380V/50Hz/3Phase (can be configured as required) |

| Hydraulic Cooling | Yes |

| Machine Size(mm) | 5000x1200x1600 |

| Net Weight | 3T |

| Jet Printer | Standard |

| Design Software | Vertex BD |

| De-coiler Capacity | 3T, Powered |

| Punch/Cutting Accuracy | ±0.5mm/0.75mm |

Applications of Rollextech Lightweight Steel Frame Machine

The Rollextech lightweight steel frame machine is widely utilized in the construction and decoration industries due to its efficient, precise, and multifunctional characteristics. Its applications include, but are not limited to, the following areas:

Building Partitions and Exterior Wall Support

In commercial and residential buildings, lightweight steel frames are often used as materials for internal partition walls, allowing for flexible space division. The Rollextech lightweight steel frame machine can produce frames that meet various specifications and shape requirements, catering to different partition design needs. Additionally, lightweight steel frames are suitable as supporting structures for exterior walls, ensuring the stability of the building structure. The high-precision processing capabilities of the Rollextech machine ensure that the frames are dimensionally accurate, thereby enhancing the overall performance of the exterior wall support system.

Ceiling Systems

Ceiling systems are an essential part of interior decoration, and lightweight steel frames serve as the framework for ceilings, providing stable support for ceiling panels while being compatible with various ceiling materials to achieve an aesthetically pleasing ceiling effect. The Rollextech lightweight steel frame machine can produce frames in various specifications and shapes to meet different ceiling design requirements, while its high-precision processing capabilities ensure the stability and safety of the ceiling system.

Decorative Projects

In interior decoration, lightweight steel frames are not only used for ceilings and partitions but also extensively for wall decorations. The Rollextech lightweight steel frame machine can produce various frame shapes that meet design requirements, allowing for compatibility with different decorative materials to fulfill complex design needs. Additionally, due to their lightweight, high strength, corrosion resistance, and ease of construction, lightweight steel frames are widely used in exhibition racks, furniture frames, and other areas. The high-efficiency production capabilities of the Rollextech machine enable a quick response to the demands in these application fields.

Renovation of Old Buildings

In the renovation of old buildings, lightweight steel frames can serve as supporting structures to enhance the overall stability and safety of the building. The Rollextech lightweight steel frame machine can produce frames that meet specific requirements based on renovation needs, providing strong support for the renovation of old buildings.

Green Building

With the development of green building concepts, lightweight steel frames are increasingly being applied in eco-friendly construction projects due to their lightweight, high strength, corrosion resistance, and ease of construction. The Rollextech lightweight steel frame machine is dedicated to reducing energy consumption and emissions, aligning with modern green building ideals and contributing to the advancement of green construction.