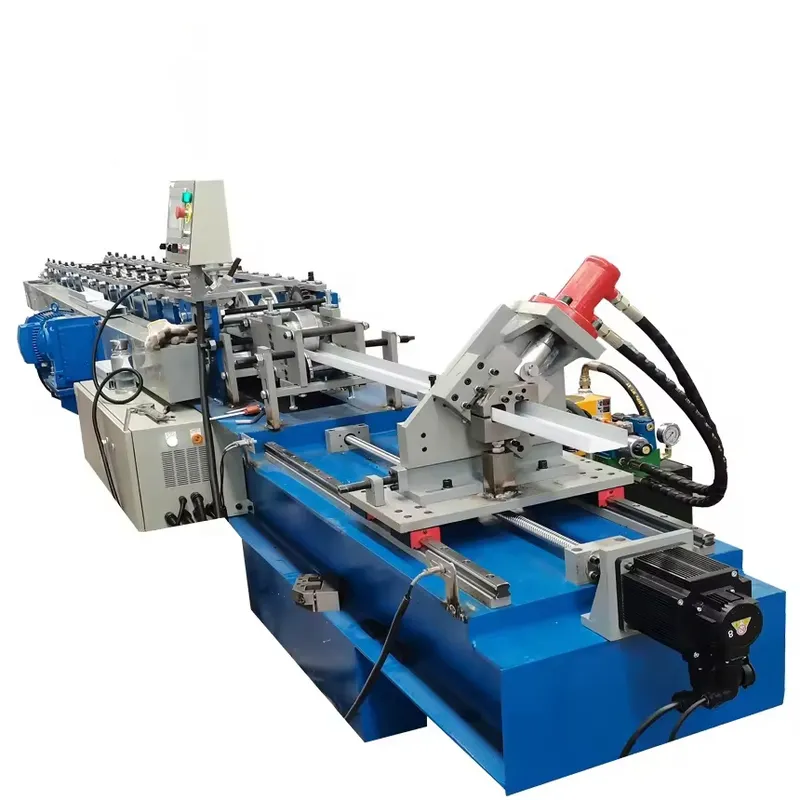

As producers of top-notch rolling door machinery, we work hard to create rolling doors with superior overall performance in addition to paying close attention to the quality of the rolling door slats throughout the manufacturing process. To guarantee precise and efficient production processes, these manufacturers’ rolling door forming machines often come with an output table, a PLC control system, an unwinder, and a host.

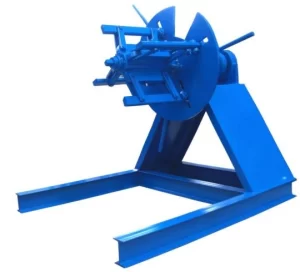

- Unwinder: The unwinder is the first component in the rolling door production line. Its job is to feed the metal coil to the subsequent process by smoothly unwinding it. Precise tension control mechanisms in high-quality unwinders make sure that the metal coil has a steady tension throughout the unwinding operation to prevent creases or breakage.

- The host, which forms the necessary rolling door slat shape by rolling and bending metal sheet via a sequence of rollers and dies, is the central component of the rolling door forming machine. In order to guarantee constant quality and accuracy of the slats generated, the host is often constructed with extreme precision. The host also has a robust power system and steady operating performance to fulfill the demands of continuous, long-term manufacturing.

- PLC control system: In charge of observing and managing every step of the manufacturing process, the PLC control system is the rolling door forming machine’s clever brain. The PLC system can precisely regulate the functioning of machinery such the unwinder, main machine, and output table via preprogrammed programs and parameters, ensuring the stability and dependability of the manufacturing process. In order to prevent bigger losses, the PLC system also has fault warning and self-protection features that may promptly halt the machine and sound an alert when the equipment malfunctions.

- The output table is the last step in the rolling door forming machine’s operation, and it is in charge of gathering, classifying, and stacking the slats that are generated. To guarantee tidy stacking and easy carriage of the slats, the premium output table has versatile adjustment features that allow it to be modified in accordance with the size and form of the slats.

- We focus on the equipment’s entire design and production process in addition to the aforementioned essential elements. They often make use of cutting-edge materials and manufacturing techniques to guarantee the equipment’s stability and longevity. In order to guarantee that clients may get prompt and efficient assistance and support while using the equipment, we also pay attention to its upkeep and maintenance and provide thorough after-sales service and technical support.

Feature of Shutter Door Machine

The rolling door forming machine is an important piece of equipment for producing rolling shutter lath. It roll-forms sheet metal to create roller shutter laths of precise shapes and dimensions. This equipment is critical in the rolling shutter manufacturing business, as it increases production efficiency and lowers production costs.

The rolling shutter door machine works by constantly rolling a metal sheet through a set of rollers to gradually deform it and create the desired shape. During the rolling process, the metal sheet is rolled and bent several times before becoming a rolling shutter door that satisfies the specifications.

Profiles of Shutter Door Machine

The benefit of a Shutter Door Machine

- High precision: To guarantee that the manufactured rolling shutter door panels have exceptionally high dimensional accuracy and shape correctness, the rolling shutter door forming machine uses modern production technology and a precise control system. This high level of accuracy extends the rolling shutter door’s service life and improves both its structural integrity and overall appearance.

- High efficiency: Rolling shutter door-forming machines significantly increase production efficiency as compared to conventional manual or semi-mechanized manufacturing processes. It can finish the uncoiling, shaping, cutting, and other operations of metal sheets rapidly and continuously, greatly decreasing production costs and the length of the production cycle.

- Simple to use: The rolling shutter door forming machine’s operational interface is often designed to be simple to use and intuitive, requiring no more than a few minutes of instruction for the operator to become proficient. To guarantee safety and dependability throughout the manufacturing process, the equipment is additionally outfitted with fault alert systems and comprehensive safety protection measures.

- Strong applicability: Rolling shutter doors made of steel, aluminum, stainless steel, and other materials may be produced using this rolling shutter door forming machine. The rolling shutter door forming machine’s broad use allows it to be highly adaptable to the demands of various sectors and clients.

- Good stability: The rolling shutter door panels produced by the rolling shutter door forming machine are stable and consistent because it uses a precise control system and a stable mechanical construction throughout the manufacturing process. This consistency lowers after-sales expenses brought on by quality issues in addition to raising the product’s overall quality.

- High flexibility: Rolling shutter door forming machines typically feature diverse production modes and modifiable parameter settings, enabling production staff to adapt parameters flexibly in accordance with real-world demands and generate rolling shutter door products that satisfy particular specifications. This adaptability boosts an organization’s ability to compete in the market while also satisfying the wide range of consumer demands.

Component of Shutter Door Machine

Machine Parts

1) Feeding

2) Rollers of Shutter Door Machine

Rollers are made of high-quality bearing steel GCr15, CNC lathed, heat-treated, and available with hard chrome coating.

3) Forming cutter

4) PLC Control system (2 types for choosing)

Easy to operate

Shutter Door MachineDecoiler (2 types for choosing)

- Manual decoiler 2. Hydraulic decoiler

Applications of rolling up door machine

Our workshop