Roof forming machines or roof panel machines play a pivotal role in contemporary architecture and have become an important force in promoting technological progress and development in the construction industry, thanks to the significant advantages of the roof panels they produce in terms of high rigidity, lightweight design, easy installation and long service life.

Above all, these machines provide roof panels with exceptional high stiffness qualities. This indicates that these roof panels may retain their structural integrity and stability even in the face of harsh weather, such as violent storms, powerful winds, and significant pressure from ice and snow, giving the structure a strong barrier of protection.

The lightweight nature of the roof panels produced by roof forming machines is another benefit. This feature not only lowers the building’s total load and increases structural safety, but it also makes construction and installation more easier and requires less manpower and time.

One of the main factors contributing to the popularity of roof panel machines is their ease of installation. The size and requirements of the roof panels may be carefully controlled via robotic manufacturing, which speeds up the building process and improves the efficiency of the on-site installation procedure.

Another important benefit of the roof panels produced by roof forming machines is their extended service life. Because of their superior materials and fine craftsmanship, these roof panels are resistant to damage from elements like wind, rain, and sunlight. They also last longer, require less upkeep and replacement, and provide long-term financial benefits to their users.

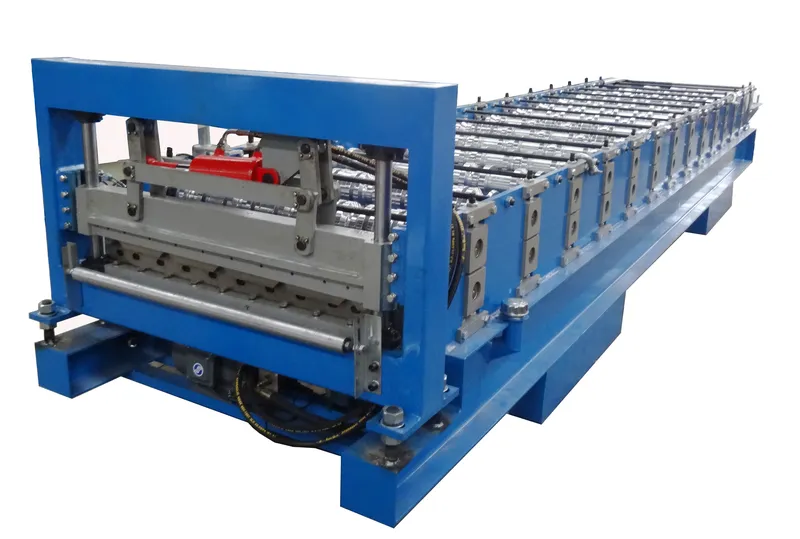

Function and design of Roofing Forming Machine

Colored steel plates, usually referred to as color plate tiles or color steel tiles, are produced using roof forming machines. Color steel plates are well-liked because of their distinct benefits, which include their sturdy construction, exceptional watertight and corrosion resistance, attractive look, and lightweight nature. These qualities make color steel plates popular in a variety of industries and areas, including agriculture, industry, and construction.

Production technology of color steel plates

Pressure technology is employed throughout the roof-forming machine manufacturing process. Using this technique, the machine shapes and compresses the coated steel plates to create a variety of waveforms. This form of treatment not only makes the color plate seem better, but it also makes it more resilient to corrosion, waterproof, and durable. Utilizing pressure technology throughout the manufacturing process guarantees the color steel plate’s precision and stability, which in turn guarantees the end product’s quality and functionality.

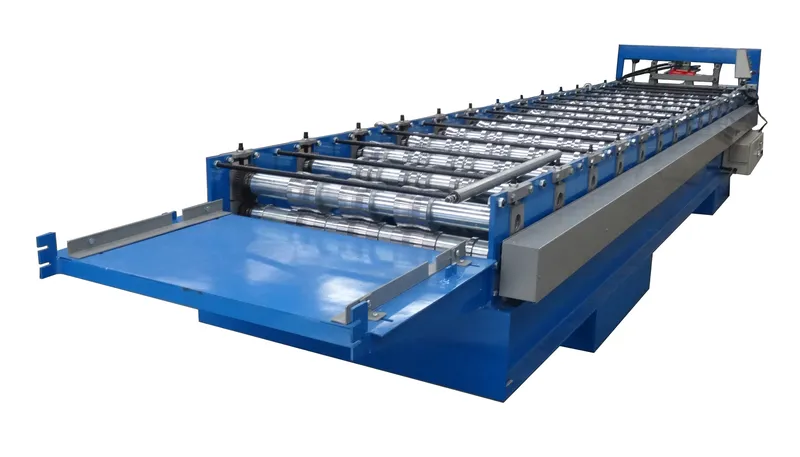

Machine Technical Parameter

| No. | Item | Parameter |

| 1 | Machine size | 7200*1500*1600mm |

| 2 | Machine weight | 5000kg |

| 3 | Machine power | 5.5kw |

| 4 | Hydraulic engine | 2.2kw |

| 5 | Roll speed | 0-20m/min |

| 6 | Roll stations | 14 |

| 7 | Roller material | 45#Steel |

| 8 | Effective width | customized |

| 9 | Feeding width | 1000mm |

| 10 | Voltage | 380V 50Hz 3PH/Customized |

| 11 | Material thickness | 0.35-0.65mm/Customized |

| 12 | Control System | Schneider/Delta/Customized |

Profile of roofing forming machine

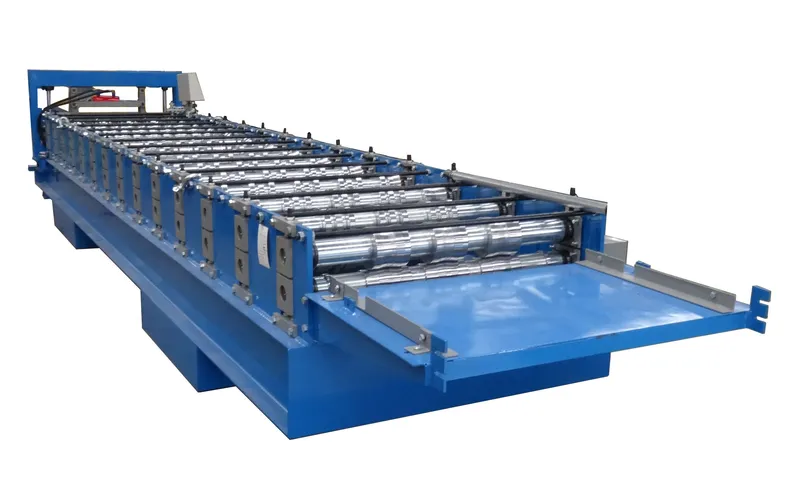

Work Flow

Decoiler→Feeding Guide Device→Pre-Cutting Device→Roll Forming System→Hydraulic Post Cutting Device→Exit Rack

Application

Color steel plates are commonly utilized in the building business. They are frequently utilized in roofing and walls. They can successfully protect the building’s structure while also improving its overall performance. Color steel plates can be used to build workshops, warehouses, and other structures in the industrial sector because of their speed of construction, light weight, high strength, energy efficiency, and environmental friendliness. Color steel plates are commonly used in agriculture to construct facilities such as greenhouses and animal homes, as well as to provide favorable circumstances for agricultural output.

The Roofing Forming Machine is essential for producing color steel plates. The color board machine can process raw materials into color steel plate products that fulfill the material quality and appearance design criteria of many industries. Thus, selecting a high-quality and reliable roof molding machine is crucial for producing high-quality color steel plate goods.

After-Sale Service

- The warranty is 12months after the client receives the machine.Within the next 12 months, we will courier the replacement parts to the client free of charge.

- We offer technical support for the entire life of our machines.

- We can send our technicians to install and train the workers in the clients’ factories at extra cost.