The Scaffolding forming machine is a sophisticated equipment developed for the continuous manufacture of scaffolding boards. It incorporates a number of process processes, including unwinding, leveling, servo feeding, punching, and continuous roll forming, resulting in one-stop manufacturing from raw materials to final products. The machine uses an innovative servo control system to precisely manage the feeding speed and forming pressure, ensuring that the scaffolding boards produced are correct in size and uniform in shape. At the same time, it is outfitted with an automated fixed-length cutting gear that can cut according to a predetermined length, significantly increasing production efficiency.

To suit the varying demands of different clients, the scaffolding forming machine may be designed based on their individual technological requirements. The thickness and breadth of the scaffolding board, as well as the form and spacing of the punches, may all be changed to meet the customer’s specific demands. This customized manufacturing approach not only matches the particular wants of clients, but it also increases the product’s market competitiveness. Furthermore, the machine is highly automated, which may eliminate manual operations, lower production costs, and provide higher economic advantages to the firm.

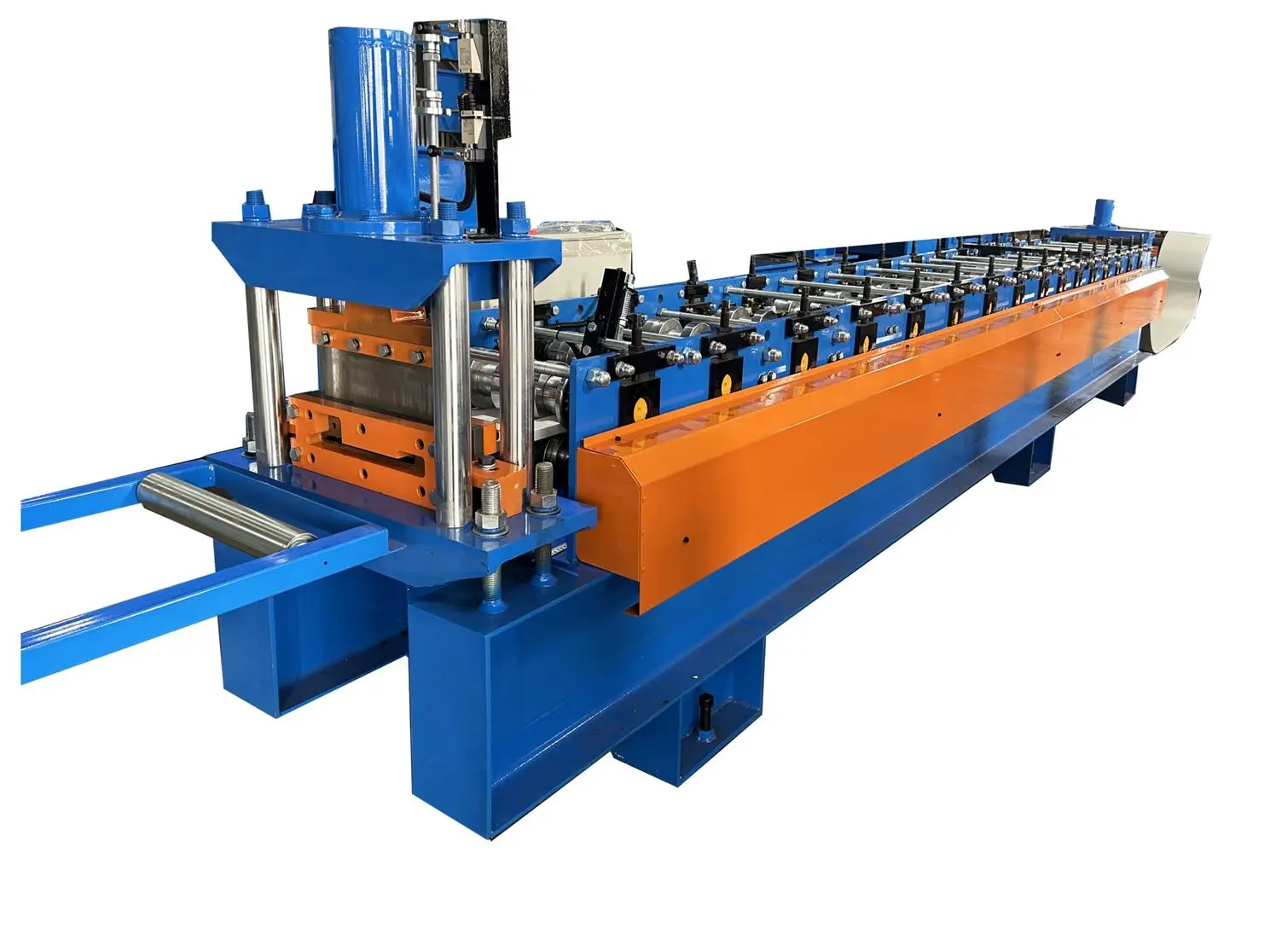

China Scaffolding Forming Machine Equipment Composition

The pedal shaping machine’s construction is sophisticated and accurate, and it consists mostly of the following major components:

- The roller is the main component of the pedal forming machine. The raw material shaping process may be precisely controlled by adjusting various angles, pressures, and amounts. The roller is often composed of high-strength, wear-resistant alloy steel to provide long-term stability and endurance.

- Transmission system: The transmission system is responsible for driving the roller’s rotation in order to accomplish raw material extrusion molding. The system typically uses precision gear transmission or chain transmission to assure transmission accuracy and stability. At the same time, the transmission system includes a motor and a reducer for adequate power supply.

- The control system is the intellectual brain of the pedal forming machine, monitoring and managing the whole manufacturing process. The control system can precisely regulate the manufacturing process by regulating factors such as the roller’s speed, pressure, temperature, and so on. In addition, the control system includes defect diagnostic and alert features to guarantee that the manufacturing process runs smoothly.

- The feeding equipment is in charge of feeding raw materials into the molding area for extrusion molding. To increase manufacturing efficiency, the gadget often uses automated feeding. At the same time, the feeding device has the capability of altering the thickness and breadth of raw materials to fulfill the manufacturing requirements of goods with varying specifications.

- Discharging device: The discharging device is responsible for removing the generated pedal products from the machine. To decrease the need for human operation, the equipment often uses automated unloading. Simultaneously, the discharge device collects, sorts, and stacks items to enable future packing and shipment.

Equipment performance of High Quality Scaffolding Forming Machine

The pedal-making machine has good performance and primarily contains the following features:

- High precision: By precisely managing factors such as angle, pressure, and number of rollers, the pedal forming machine can accomplish high-precision form processing. This assures product size precision and form consistency, while also improving product quality and market competitiveness.

- High efficiency: The pedal forming machine offers the benefits of efficient and unattended manufacturing. The equipment’s autonomous control system and innovative transmission system allow for high-speed manufacturing while drastically lowering production costs and improving efficiency. Simultaneously, equipment stability and durability enable long-term production stability and dependability.

- Strong durability: The rollers, transmission systems, and other critical components of the equipment are often composed of wear-resistant and durable materials to assure the equipment’s serviceability and stability. This minimizes the cost of maintenance and equipment replacement, resulting in increased economic advantages for the organization.

Application of Scaffolding Forming Machine

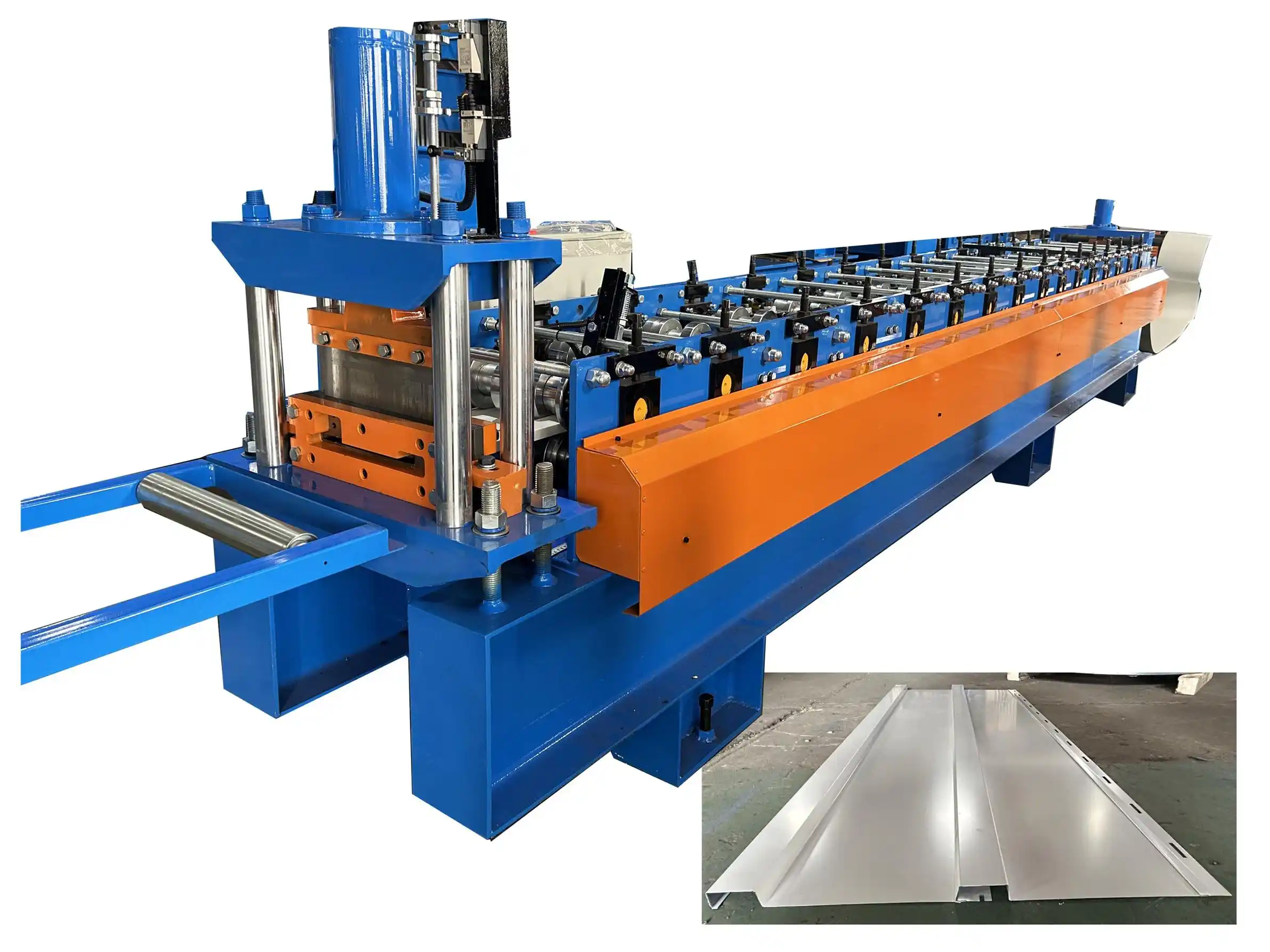

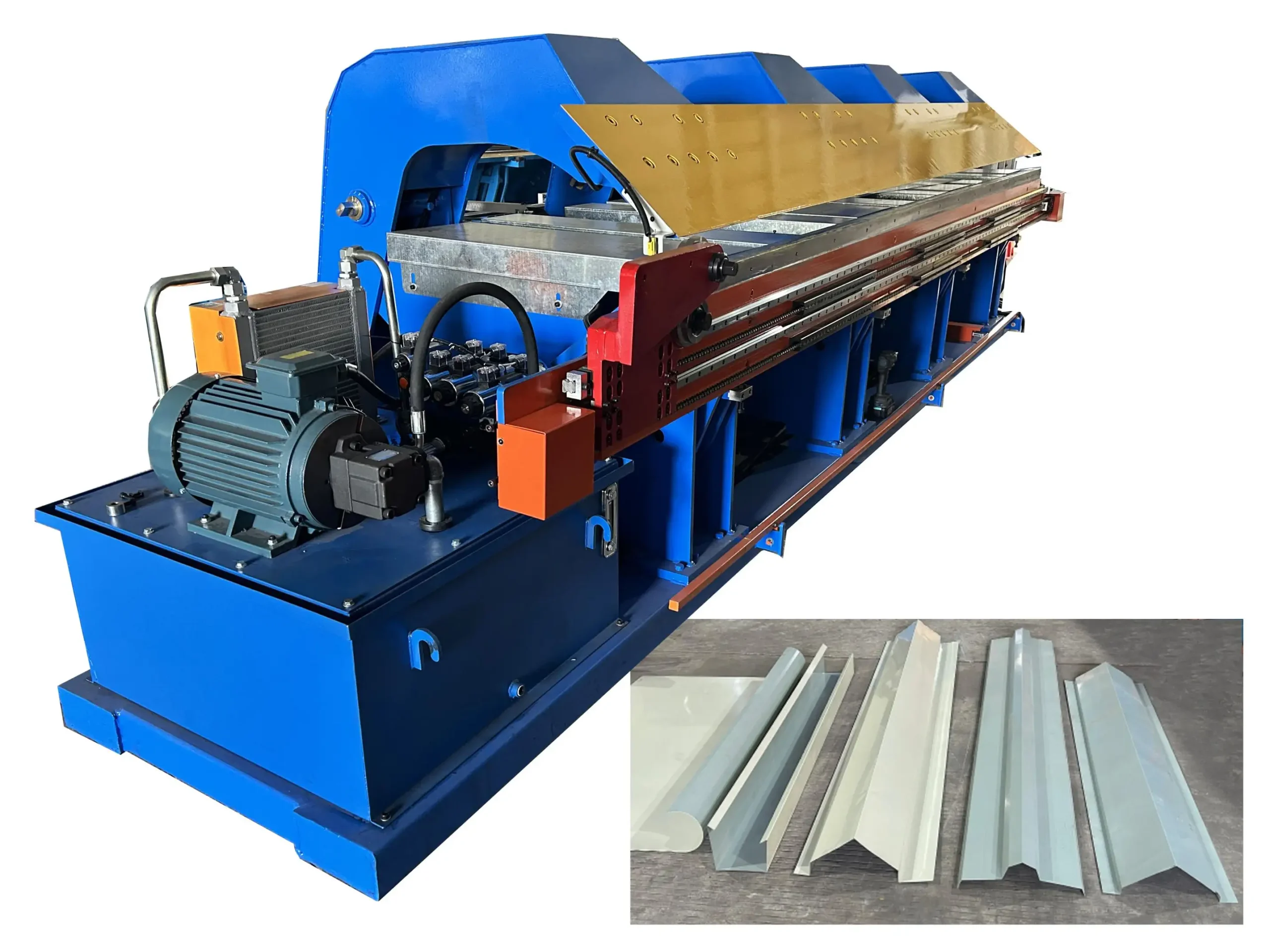

The pedal roll forming machine is widely used in construction, manufacturing and other industries, especially in the production of building scaffolding.

Through the roll forming of materials such as steel plates and aluminum plates, pedal products that meet the requirements can be produced quickly and efficiently.Profiles of spandrel machine

Component of Scaffolding Forming Machine

Machine Parts

1) Feeding

2) Rollers of Machine

Rollers are made of high-quality bearing steel GCr15, CNC lathed, heat-treated, and available with hard chrome coating.

3) Forming cutter

4)PLC Control system (2 type for choosing)

Easy to operate

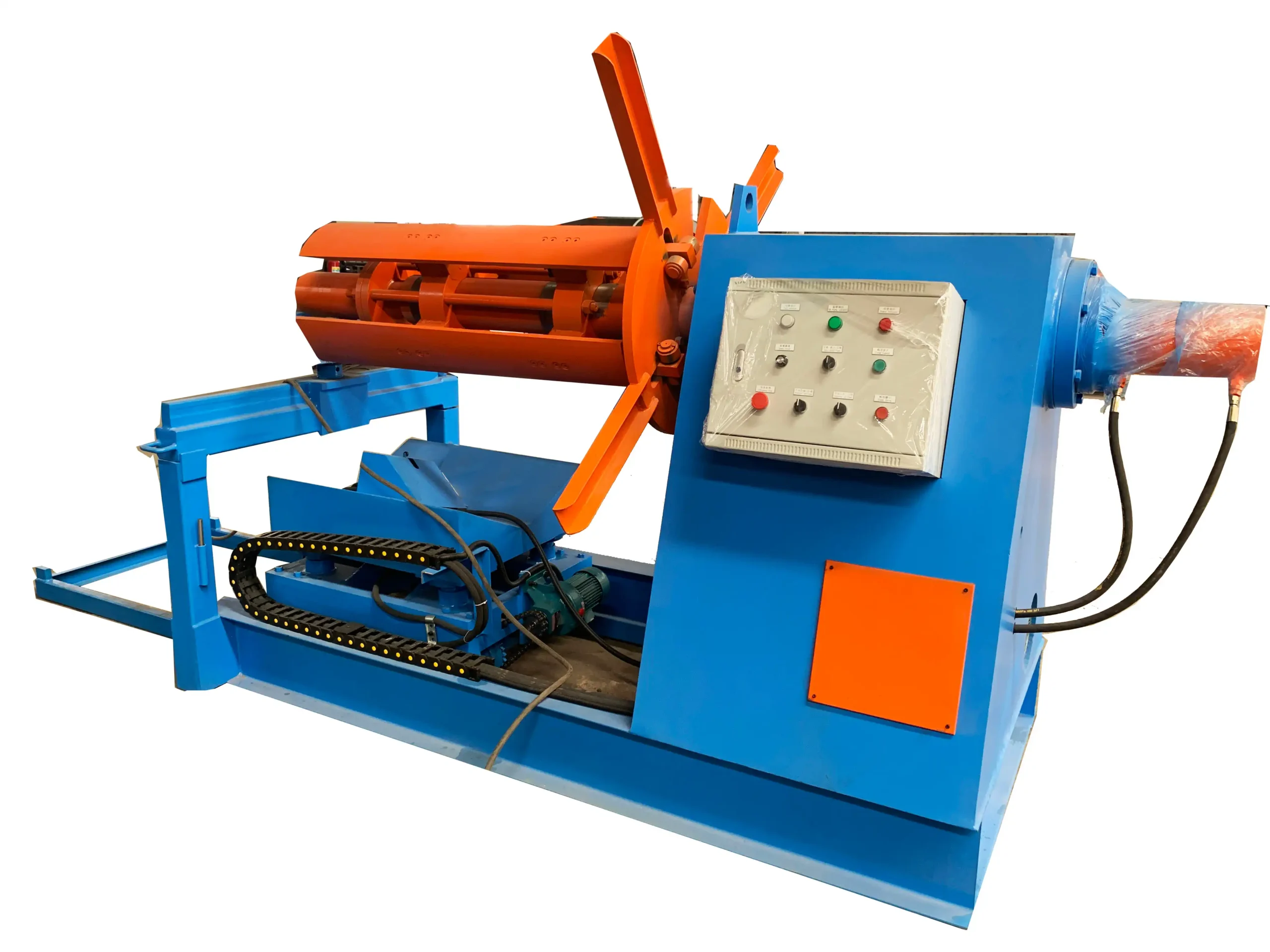

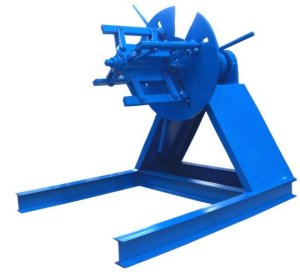

5)Decoiler (2 type for choosing)

1. Manual decoiler 2. Hydraulic decoiler

Our Worksop