The Shutter Door Machine is a state-of-the-art automated device intended to produce rolling door slats precisely and efficiently. The most recent automation technology is integrated into this rolling door roll forming machine, enabling completely automated operation from raw material input to completed product output and significantly increasing production efficiency.

The machine’s easy-to-use interface makes it possible for users to rapidly become proficient in a variety of operations. In addition, its high-precision control system guarantees that the rolling door slats’ dimensions, form, and functionality adhere to stringent standards, guaranteeing the product’s stability and quality.

The rolling door forming machine prioritizes user comfort and safety in addition to its effective production capacity. The operator may assure smooth production progress by monitoring the equipment’s working state in real time and making timely adjustments to the production parameters using the intelligent control system. Furthermore, the apparatus is outfitted with extensive safety precautions to efficiently avert any problems while in use.

Shutter Door Roll Forming Machine How it works

The roller shutter forming machine is an essential piece of equipment that is used in the manufacture of roller shutter doors. It skillfully adapts metal sheets into the precise profiles needed for roller shutter doors using roll-forming technology, satisfying the requirements of several application situations.

The metal sheet is first put into the roller shutter forming machine in order for it to function. The sheet travels through a sequence of precisely engineered rollers. In addition to their superior hardness and wear resistance, these rollers are positioned and inclined precisely to allow for the progressive and uniform bending of the metal sheet throughout the rolling process.

The metal sheet is guaranteed to retain consistent quality and accuracy throughout the forming process by means of the continuous and well-coordinated rolling and bending operation. The flat metal sheet is progressively changed into roller shutter door slats with precise sizes and forms by the operation of this sequence of rollers. These slats can completely satisfy the usage requirements of roller shutter doors because to their exceptional structural strength and longevity, in addition to their constant look quality.

It is important to note that the roller shutter forming machine considerably lowers the manufacturing costs for the roller shutter sector in addition to increasing production efficiency. This machine can finish the metal sheet forming process faster than conventional manufacturing techniques, which lowers labor costs and production cycles. The usage rate of metal sheets has also significantly increased as a result of the use of cutting-edge roll forming technology, thus lowering the cost of raw materials.

Profiles Produced by the Shutter Door Machine

The machine is capable of producing a wide range of shutter door profiles, tailored to various shapes and sizes, depending on the specific requirements of the project. This flexibility allows for the creation of custom roller shutters suitable for different applications.

Advantages of the Shutter Door Roll Forming Machine

One of the major benefits of the roller shutter door roll forming machine is its high precision and efficiency. It is highly versatile, capable of handling different materials and specifications, making it suitable for use across various sectors such as construction, industrial, and commercial environments.

By employing this machine, manufacturers can significantly reduce labor requirements while enhancing the overall production speed and consistency of the shutter door slats. Additionally, the machine ensures uniformity and stability across all produced pieces, ensuring that the final products are of superior quality.

With its efficiency, operational stability, and flexibility, the shutter door roll forming machine is an indispensable asset in modern shutter door manufacturing, helping businesses meet the growing and diverse demands of the market.

Component of Shutter Door Machine

Machine Parts

1) Feeding

2) Rollers of Shutter Door Machine

Rollers are made of high-quality bearing steel GCr15, CNC lathed, heat-treated, and available with hard chrome coating.

3) Forming cutter

4)PLC Control system (2 type for choosing)

Easy to operate

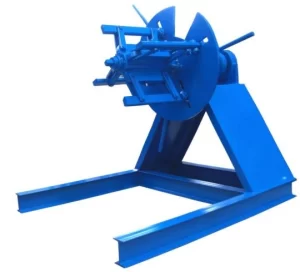

Shutter Door MachineDecoiler (2 type for choosing)

- Manual decoiler 2. Hydraulic decoiler