The rolling door forming machine is an intricate system made up of many parts, each of which is essential. The rolling door forming machine can effectively create rolling door slats that satisfy the specifications via precision control and cooperative operation.

Main components of Shutter Door Roll Forming Machine

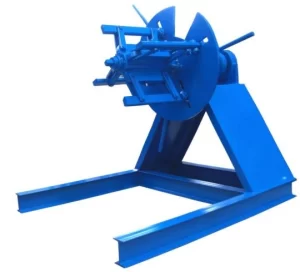

Unwinder

Function: In charge of unraveling the rolling door’s raw materials (aluminum, steel, and so forth) in order to get them ready for further processing.

feeder

Function: Consistently and smoothly feed the unwound materials into the main machine for the forming procedure. The quality of the forming that follows is significantly influenced by the feeder’s precision and steadiness.

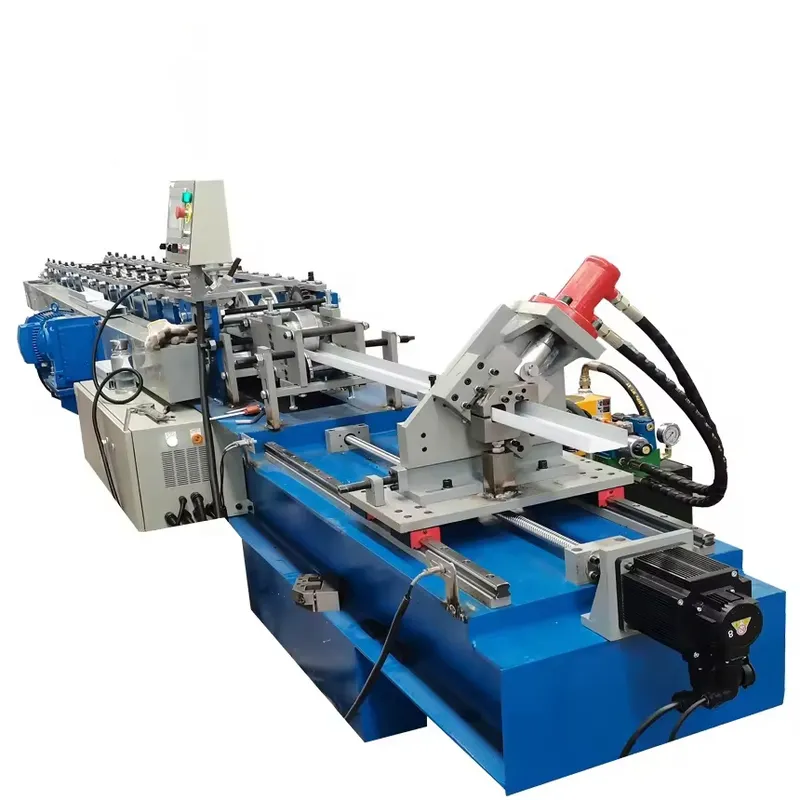

Main machine

Function: Forming molds and rollers are the primary machine’s essential parts. The feed materials are pressed into the required form of rolling door slats by means of the collaboration of the molds and rollers. The product’s forming quality and production efficiency are closely correlated with the design, manufacture, and debugging level of the main machine.

Post-cutting machine

Function: The post-cutting machine is in charge of cutting the rolling door slats into the necessary length after they have been made. The yield of the product and the efficiency of manufacturing are significantly influenced by the post-cutting machine’s speed and precision.

PLC system for computer control

Function: The rolling door forming machine’s “brain,” the PLC computer control system, is in charge of coordinating the coordinated efforts of numerous parts to produce automated production. PLC can precisely control the time nodes and process parameters of each link, including unwinding, feeding, forming, and cutting, through preset programs and parameters, guaranteeing product quality and production efficiency.

Table of output

Function: In order to make subsequent assembly and transportation easier, the output table is in charge of receiving and stacking the formed rolling door slats. Operator safety, accessibility, and product stacking stability should all be considered in the output table’s design.

Feature of Shutter Door Roll Forming Machine

A shutter door roll forming machine is a piece of automated equipment that is used to make rolling shutter doors. Its qualities and benefits include:

Automated manufacturing: The shutter door roll forming machine has an advanced automated control system that allows for continuous and efficient production, significantly increasing production efficiency.

Precision forming: The machine uses advanced roll forming technology to properly punch metal sheets into rolling shutter door sheets with specific dimensions and forms, ensuring product quality and consistency of requirements.

Saving labor expenses: Because of the equipment’s high level of automation, manual operation in the production process is reduced, as is the scrap rate, resulting in lower labor and raw material costs.

Improving production efficiency: Using a shutter door roll forming machine for production can significantly increase the speed and output of rolling shutter door sheets, allowing you to fulfill market demands.

Profiles of Shutter Door Roll Forming Machine

The benefit of Rolling Up Shutter Door

- Simple to operate: There are many easy methods for users to open and shut the rolling door.

- Enhanced productivity: Automated processes minimize human intervention and boost work output.

- The movable door is perfect for tiny rooms since it takes up less room when folded up.

- In order to increase security, rolling door machines usually include anti-theft measures. ability to adapt to a variety of environments, such as business, industry, and homes.

- Installing anything customized may be done depending on the requirements of the user and the environment.

- Easy integration is compatible with current smart home and security systems.

- A lengthy service life is guaranteed by the rolling door machine’s high-quality construction and design.

Component of Shutter Door Machine

Machine Parts

1) Feeding

2) Rollers of Shutter Door Machine

Rollers are made of high-quality bearing steel GCr15, CNC lathed, heat-treated, and available with hard chrome coating.

3) Forming cutter

4)PLC Control system (2 type for choosing)

Easy to operate

Shutter Door MachineDecoiler (2 type for choosing)

- Manual decoiler 2. Hydraulic decoiler

Applications of rolling up door machine

Our Workshop

At Liliumfaucet, our workshop is where innovation meets precision. Equipped with state-of-the-art machinery and staffed by skilled professionals, we focus on producing high-quality products that meet the highest standards. From design to assembly, every step of the process is meticulously managed to ensure that each product is durable, functional, and beautifully crafted.