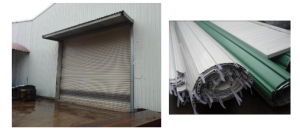

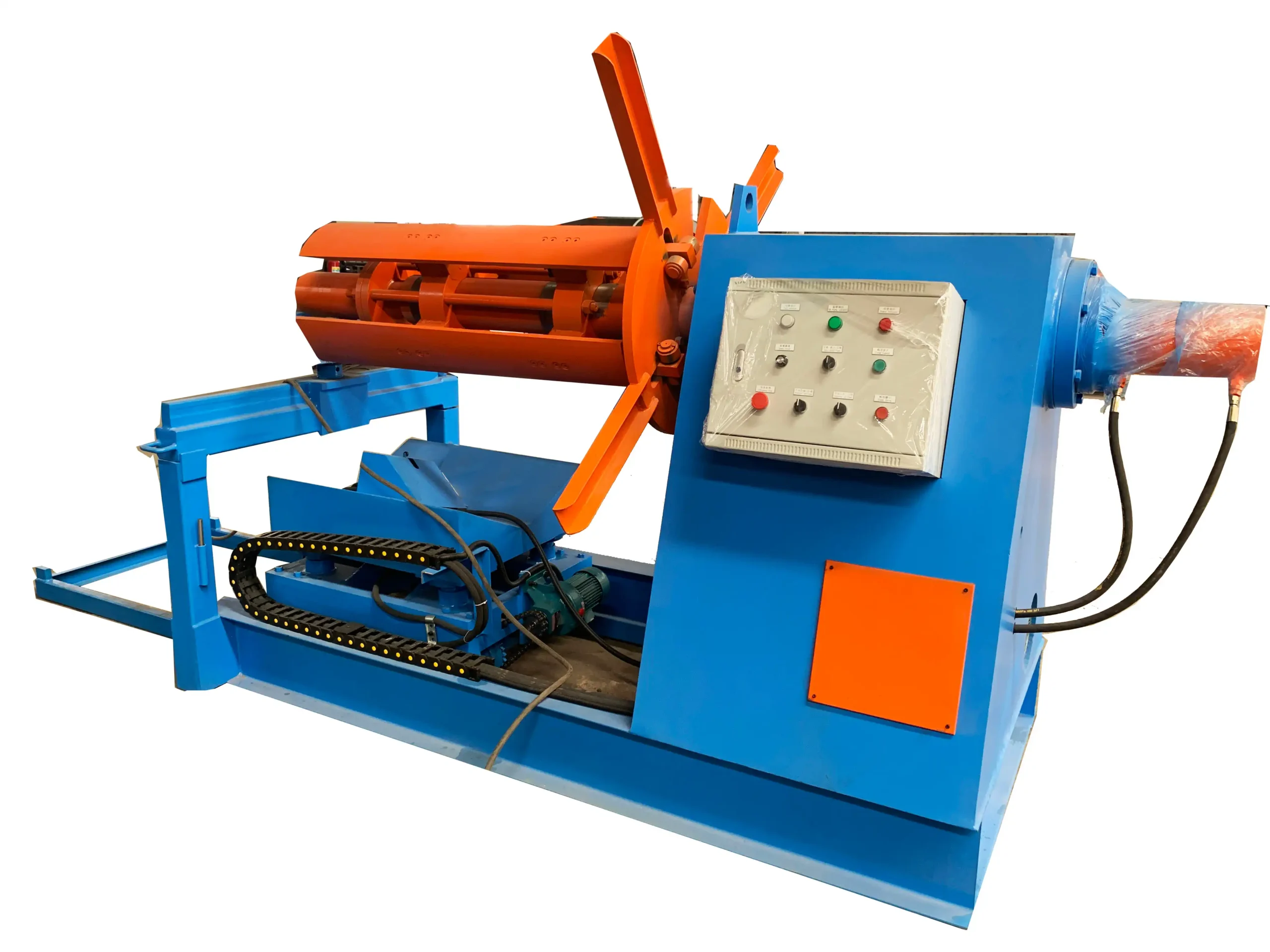

Introduction of Shutter Door Rolling Machine

As a common safety protection facility, rolling doors are widely used in many fields such as commercial, industrial and residential. Choosing a high-quality rolling door machine is the best solution to ensure the production of efficient, safe, and beautiful rolling doors. Our rolling door rolling machine combines advanced mechanical design with electronic control technology to produce rolling door strips accurately and consistently. It can maintain efficient and stable operation whether in a high-pressure, high-intensity long-term production environment or in small batch production. Through automated production methods, energy consumption and production costs are greatly reduced, while production efficiency is greatly improved. It is easy to operate, and even novice operators can quickly master the skills of use, bringing efficient and low-cost production solutions to enterprises.

The rolling door rolling machine is an automated equipment dedicated to the production of metal sheets for rolling doors. The equipment uses an efficient control system and advanced roll forming technology to accurately stamp metal sheets into rolling door strips that meet specifications. The equipment has a compact design and is easy to operate. It can effectively improve production efficiency and reduce raw material waste. It is one of the indispensable equipment in modern industrial production.

Features of Shutter Door Rolling Machine

- Automated production: The use of advanced automatic control systems can achieve continuous and stable production and significantly improve production efficiency. The system supports one-button operation, allowing operators to easily master the equipment and reduce manual intervention.

- Precise forming: Using modern roll-forming technology to ensure that the size and shape of each rolling door panel are accurate and consistent, ensuring the stability of product quality.

- Cost saving: Due to the high level of automation, manual operation and waste generation are reduced, reducing production costs. The equipment can adjust production parameters according to demand to maximize the use of raw materials.

- Improve production efficiency: The machine can produce rolling door slats quickly and efficiently, which can meet the market demand for high-quality rolling doors.

- Small footprint: The machine is small in size and occupies a small area, which is very suitable for production workshops with limited space. The rolling door strips can be rolled up during the production process, occupying little space and effectively utilizing the workshop space.

- Powerful customization capabilities: The equipment can customize rolling door panels of different sizes, materials and styles according to customer needs, which can meet the specific requirements of different customers.

- Easy to integrate and expand: The equipment can be easily integrated with intelligent manufacturing systems or existing production lines to achieve data exchange and remote control. Its excellent scalability enables the production line to be simply expanded and adjusted as production needs grow.

- Durable materials and high strength: The equipment is made of high-quality materials, precision processed and heat treated, ensuring high performance and stability under long-term use. Even in a high-intensity production environment, the equipment can still maintain excellent durability.

Application of Shutter Door Rolling Machine

The rolling door rolling machine is suitable for various fields that require the use of metal rolling doors, and is widely used in the following industries:

- Commercial buildings: Used for the production of rolling doors in shopping malls, supermarkets, stores, and other places, providing high-security protection.

- Industrial field: Used for the manufacture of rolling doors in factories, warehouses, garages, and other places to ensure the safety of industrial environments.

- Residential areas: Provide safety protection doors for residential areas, villas, and other residences to enhance the sense of security of residents.

- Parking lots and garages: Manufacture high-quality and durable garage doors and parking lot rolling doors to ensure vehicle safety.

Why Choose Our Shutter Door Rolling Machine

- Technical advantages: Our rolling door rolling machine combines advanced mechanical design and electronic control technology, with high equipment precision and high production efficiency, ensuring that your production needs are met.

- High-quality materials and processes: The equipment uses high-quality steel and wear-resistant materials to ensure long-term stable operation and is not prone to failure. All parts are strictly quality-controlled and inspected to ensure that each machine has excellent performance.

- Energy saving and environmental protection: The equipment adopts advanced automated production technology, which reduces labor costs and resource waste, greatly reduces production costs, and improves production efficiency. Our equipment has also passed environmental protection certification and meets environmental protection standards, helping enterprises achieve sustainable development.

- Simple operation and maintenance: Our equipment design focuses on user experience, the operation is simple and easy to understand, and the maintenance is convenient. Customers can get started in a short time. We also provide comprehensive after-sales service to ensure long-term and stable operation of the equipment.

- Customization service: We provide personalized customization services, and can adjust the equipment configuration according to the special needs of customers to meet different production requirements. Whether it is equipment size, production speed, or machine functionality, it can be customized according to customer needs to ensure that customers get the best use experience.

Our rolling door rolling machine is your best choice for producing high-quality, safe, and reliable rolling doors. It can not only significantly improve production efficiency, and reduce energy consumption and production costs, but also provide you with flexible customization options and excellent after-sales support. Whether it is commercial, industrial, or residential fields, our equipment can provide you with a perfect solution. If you are looking for efficient, stable, and competitive rolling door production equipment, our rolling door machine is undoubtedly your ideal choice.

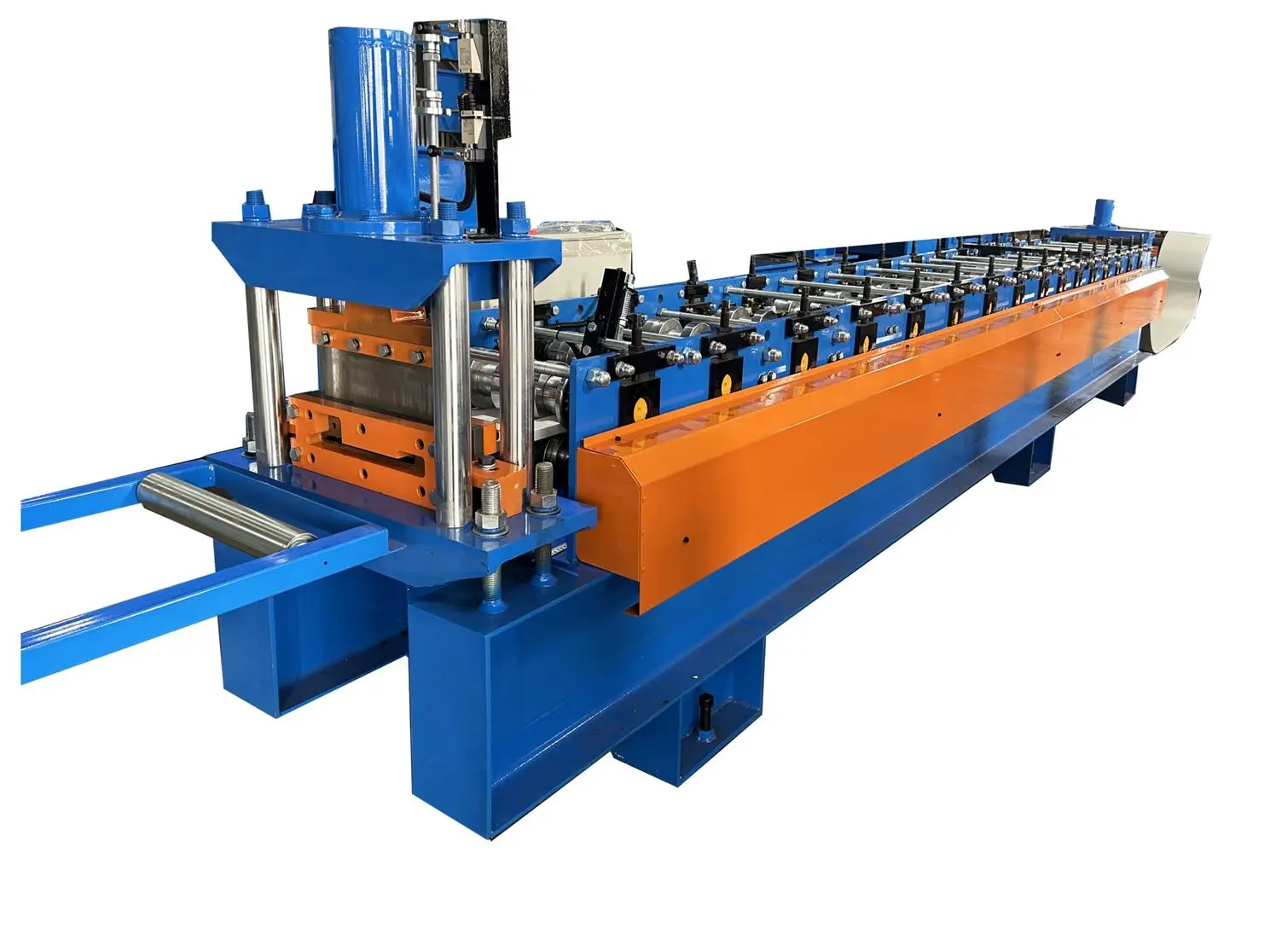

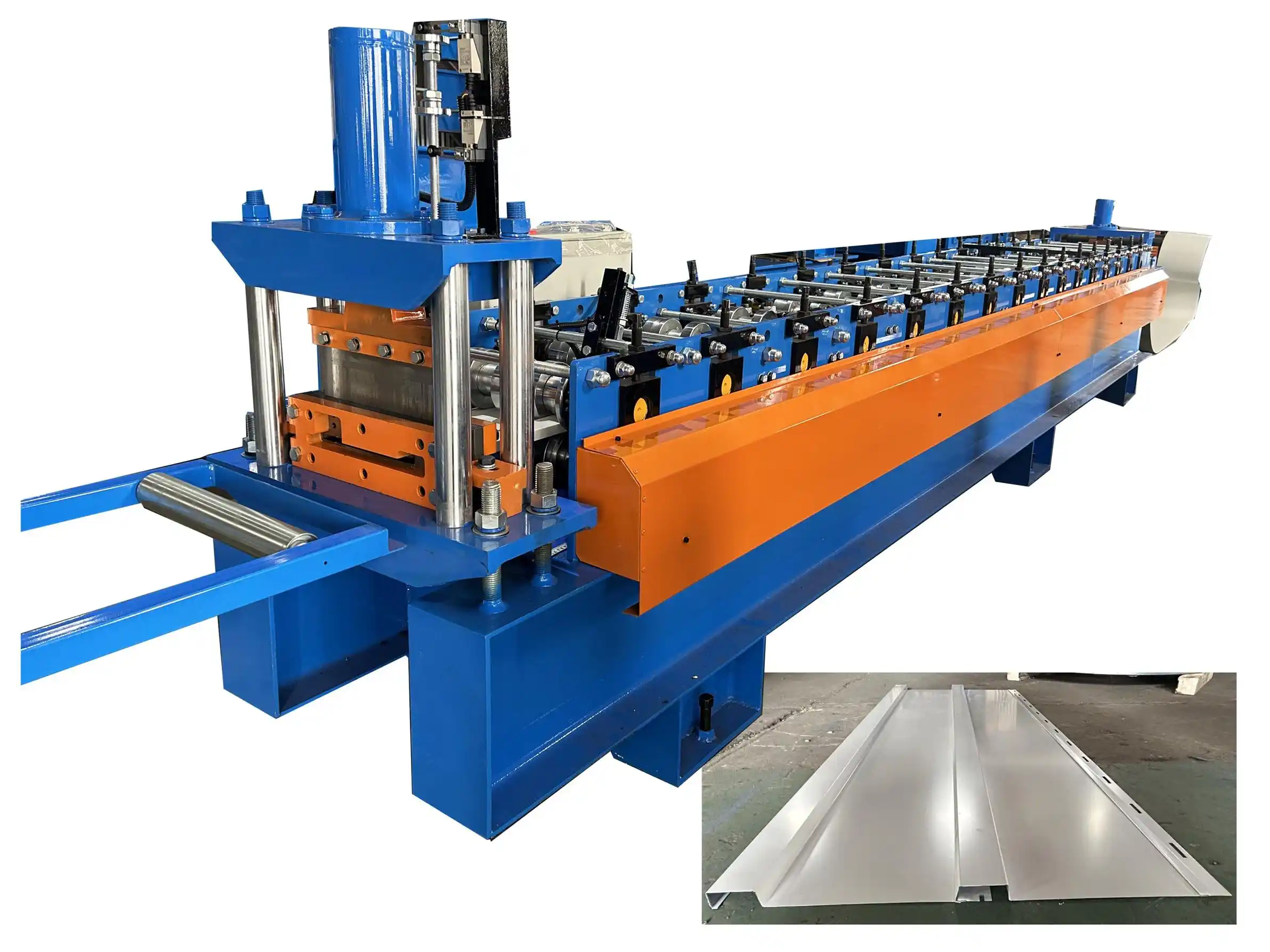

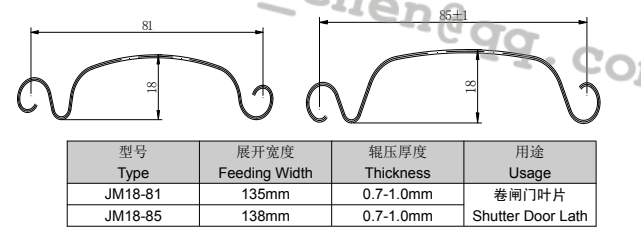

Profiles of Shutter Door Rolling Machine

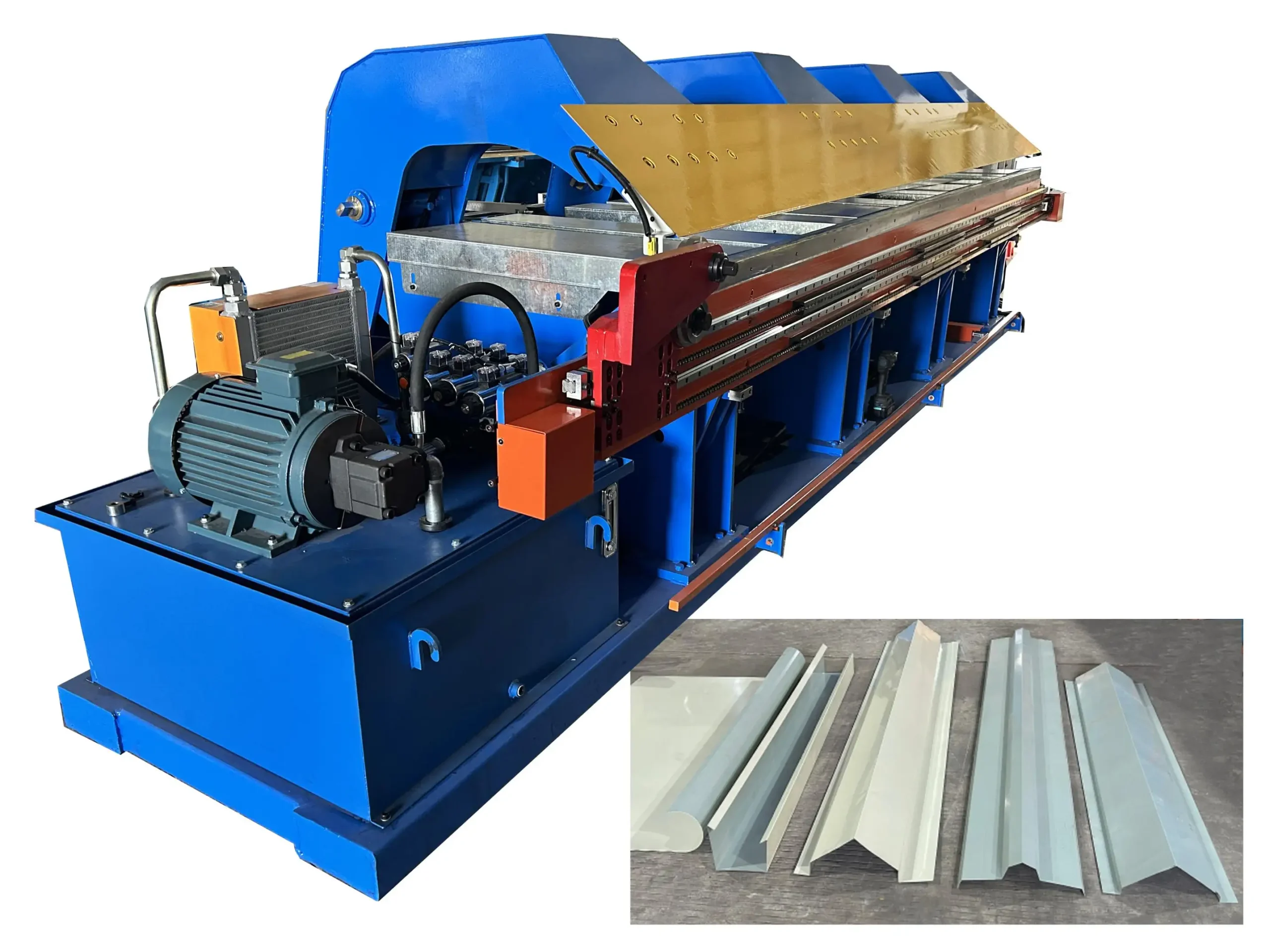

Component of Shutter Door Machine

Machine Parts

1) Feeding

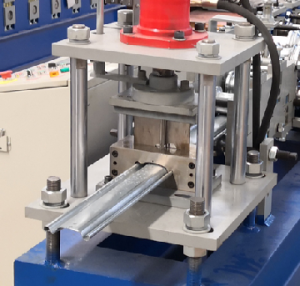

2) Rollers of Shutter Door Machine

Rollers are made of high-quality bearing steel GCr15, CNC lathed, heat-treated, and available with hard chrome coating.

3) Forming cutter

4)PLC Control system (2 type for choosing)

Easy to operate

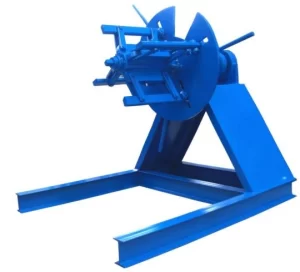

Shutter Door MachineDecoiler (2 type for choosing)

- Manual decoiler 2. Hydraulic decoiler

Applications of rolling up door machine