The term spandrel machine may not directly refer to a specific mechanical equipment, but a general term for equipment or processes related to the production, processing or installation of spandrel materials. In the field of home decoration, spandrels (including indoor/outdoor ceiling spandrels, corr spandrels, rib spandrels and plain spandrels) are popular for their unique charm and superior performance.

Spandrel machine may be a general concept, which covers various equipment and processes related to the processing, production or installation of spandrels. As the preferred material for home decoration, spandrels have won wide recognition in the market for their unique charm and superior performance.

Features of panels with spandrels

- Both ornamental and functional: Spandrel panels, a pioneer in interior design, not only enhance the room’s aesthetic, but also seamlessly merge the ceiling and wall to provide a striking visual impact. Because of its non-toxic and mildew-proof qualities, the home atmosphere is safe and healthy.

- The ideal combination of premium quality and reasonable cost: Despite their superior quality, spandrel panels are still relatively reasonable, which makes them accessible to all customers who aspire to a better life.

- Rich workmanship and a variety of materials: Quality materials like colour steel plates, aluminium alloys, and stainless steel are used, together with cutting-edge techniques like roller coating, laminating, and sophisticated printing, to produce a range of colours and styles that satisfy many styles’ decorative requirements.

- Moderate thickness and robust durability: The spandrel board’s low weight and ease of installation are preserved while its durability is guaranteed by the several thickness choices available, such as 0.55mm, 0.6mm, or 0.7mm.

widely used to satisfy a range of needs:

In house décor, espandrel planks are especially well-suited for ceiling construction. Their lightweight, strong, and elegant qualities provide the living room, bedroom, foyer, balcony, and other areas a unique shine. Its remarkable flexibility and limitless creative potential also make it popular in other industries, such as commercial space decorating and advertising décor.

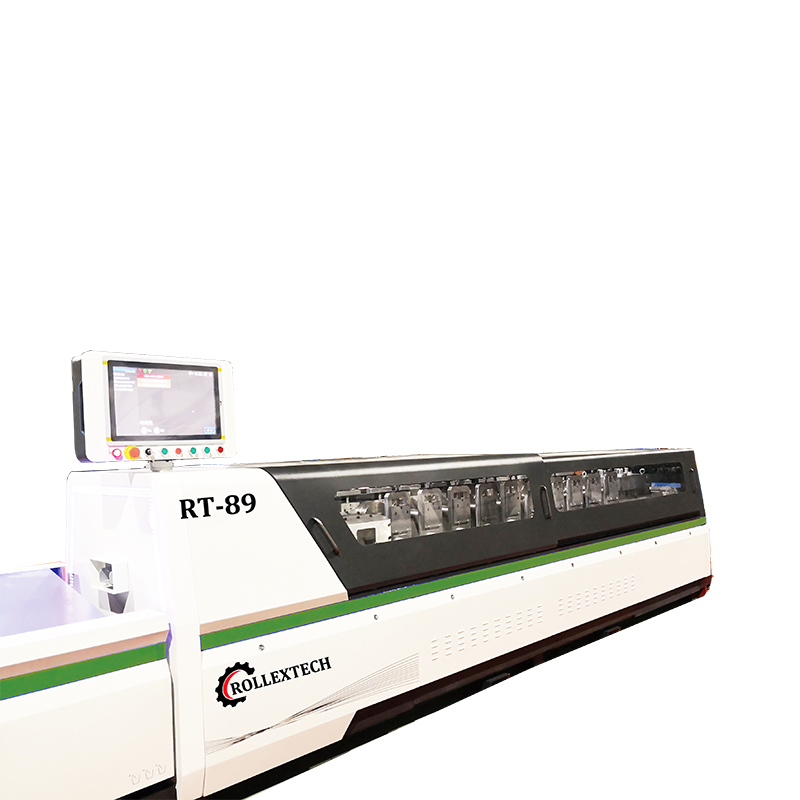

Profiles of spandrel machine

Component of spandrel machine

Machine Parts

1) Feeding

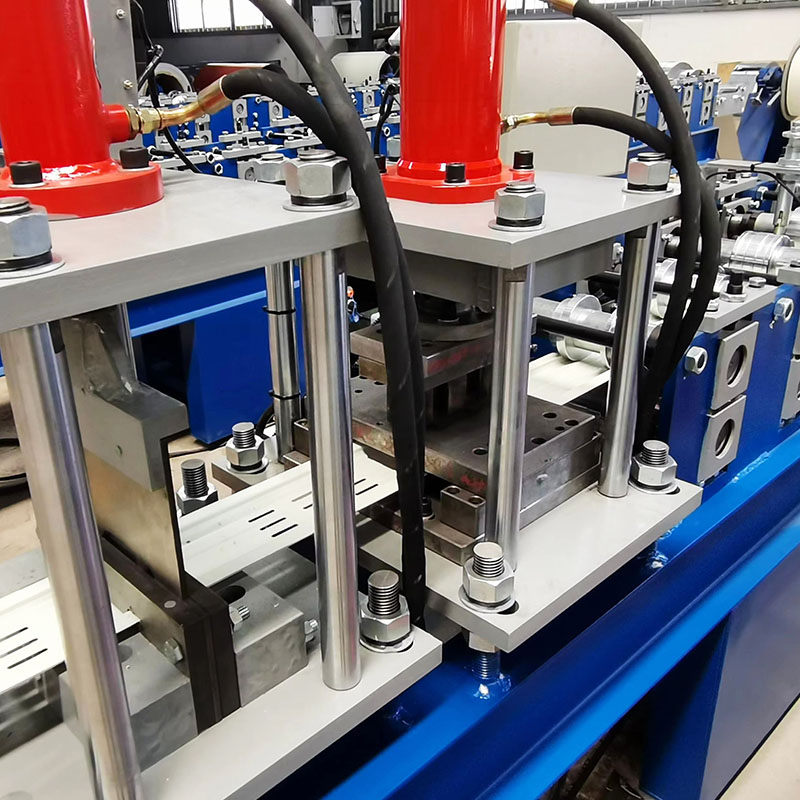

2) Rollers of Machine

Rollers are made of high-quality bearing steel GCr15, CNC lathed, heat-treated, and available with hard chrome coating.

3) Forming cutter

4)PLC Control system (2 type for choosing)

Easy to operate

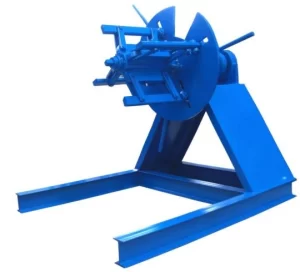

5)Decoiler (2 type for choosing)

- Manual decoiler 2. Hydraulic decoiler

Why Choose SKD Machine

- Wide Selection:PU Foaming line,Light frame machine,CZ purlin machine and all kinds of roll forming machine

- Quality assurance:The product has undergone rigorous design, high standard processing and inspection, and the finished product is tested for multiple times.

- Professional Team:We have a professional team with more 20 years experience in design, R&D and QC team strictly supervised every step of machine in production.

- Worry-free Service:24 hours on line to meet your requirements and provide the technical support for the whole life of our machines.

- Guarantee period:Within 1 year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts.

- Easy operation:All machine controlling by PLC computer controlling system.

FAQ

1. What is a Spandrel Machine?

A Spandrel Machine is a specialized piece of equipment used in the construction industry to produce spandrel panels, which are architectural elements typically found between the top of a window on one story and the bottom of a window on the story above it.

2. What materials can a Spandrel Machine work with?

Spandrel Machines can work with a variety of materials, including glass, aluminum, and composite panels, depending on the specific machine and its capabilities.

3. How does a Spandrel Machine operate?

A Spandrel Machine operates by feeding raw materials into the machine, where they are cut, shaped, and assembled into spandrel panels according to pre-set specifications. The process typically involves precision cutting, bending, and sometimes bonding or welding.

4. What are the key features of a Spandrel Machine?

Key features of a Spandrel Machine include high precision cutting tools, automated material handling, customizable settings for different panel designs, and efficient production speeds. Some machines also offer advanced features like CNC control and real-time monitoring.

5. What are the benefits of using a Spandrel Machine?

Benefits include increased production efficiency, consistent panel quality, reduced material waste, and the ability to quickly adapt to different design specifications. These machines also help in maintaining high safety standards during production.

6. How do I maintain a Spandrel Machine?

Maintenance typically involves regular cleaning, lubrication of moving parts, inspection of cutting tools for wear and tear, and software updates. It is essential to follow the manufacturer’s maintenance schedule and guidelines to ensure optimal performance and longevity of the machine.

7. Can a Spandrel Machine be customized?

Yes, many Spandrel Machines can be customized to meet specific production requirements. Customizations may include modifications to handle different materials, adjustments to cutting and shaping capabilities, and integration with other production line equipment.

8. What should I consider when purchasing a Spandrel Machine?

Consider factors such as the machine’s compatibility with your materials, production capacity, ease of operation, maintenance requirements, and the level of technical support offered by the manufacturer. It is also important to evaluate the total cost of ownership, including initial investment and long-term operational costs.

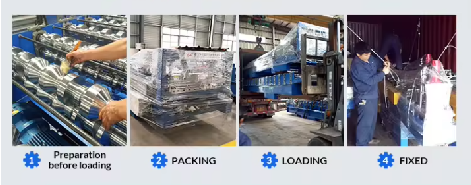

9. How long does it take to set up and start using a Spandrel Machine?

The setup time can vary depending on the complexity of the machine and the level of customization required. Typically, it can take anywhere from a few days to a few weeks to fully set up, calibrate, and start using a Spandrel Machine.

10. Where can I find technical support and spare parts for my Spandrel Machine?

Technical support and spare parts are usually available through the machine’s manufacturer or authorized dealers. It is important to establish a good relationship with your supplier to ensure prompt and reliable support when needed.