The Spandrel Roll Forming Machine’s qualities are strongly connected to the quality, production efficiency, and diverse demands of the window sills. The window sill machine has the following characteristics: raw material variety, high accuracy and efficiency, diversification and customisation, broad application and durability, automation and intelligence. These attributes make the window sill machine a must-have piece of equipment in today’s interior decorating business.

Features of Spandrel Roll Forming Machine

Applicable to a variety of raw materials

Spandrel Roll Forming Machine can process a variety of raw materials, including color steel plates, aluminum alloys, stainless steel, etc. Through different processing techniques, such as rolling, laminating and printing, these raw materials can be processed into lintel products of various styles and specifications to meet different design requirements.

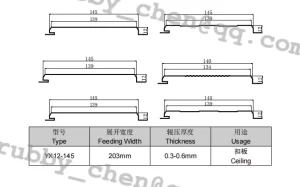

Flexible optional thickness: This equipment can handle raw materials of various thicknesses. Common thicknesses are 0.55mm and 0.6mm. Users can choose the appropriate raw material thickness according to specific decoration needs.

High precision and high efficiency

Precise processing: Spandrel Roll Forming Machine uses advanced processing technology and precision cutting equipment to ensure that each lintel is accurate in size and regular in shape, meeting strict quality standards.

Efficient production: Compared with traditional manual processing methods, the use of lintel forming machines can greatly improve production efficiency. The machine can quickly and accurately complete a large number of lintel processing tasks, reducing production costs and improving market competitiveness.

Diverse designs and customized services

Diverse designs: Spandrel Roll Forming Machine can process lintels of various designs and patterns to meet users’ diverse needs in aesthetics and functionality. Many manufacturers also provide customized services, which can tailor lintel products according to customers’ specific requirements, space dimensions and design styles.

Wide application and excellent durability

Lintels produced by lintel forming machines are widely used in architectural decoration, especially in commercial buildings, residential projects and indoor spaces such as living rooms, bedrooms, foyers, balconies, etc. The lintels produced by this machine are non-toxic, anti-mildew, high-quality and reasonably priced, so they are widely used and recognized in the market.

Excellent durability: The high-quality raw materials and innovative manufacturing processes used in lintel forming machines make the lintels produced by them have excellent durability and anti-aging properties, which can maintain their beauty and functionality for a long time, reducing the need for later maintenance and replacement.

Automation and intelligence

Automated production: The modern Spandrel Roll Forming Machine is equipped with an advanced automation control system, which can realize automatic feeding, cutting and forming and other production links, greatly reducing manual participation and improving production efficiency.

Intelligent monitoring: Some high-end lintel forming machines are equipped with an intelligent monitoring system that can monitor multiple key factors in the production process in real time, such as temperature, pressure, speed, etc., to ensure the stability and safety of the production process, thereby improving product consistency and quality.

Profiles of spandrel machine

Running Video of Spandrel roll forming machine

Component of Spandrel Roll Forming Machine

Machine Parts

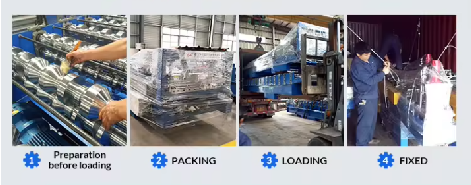

1) Feeding

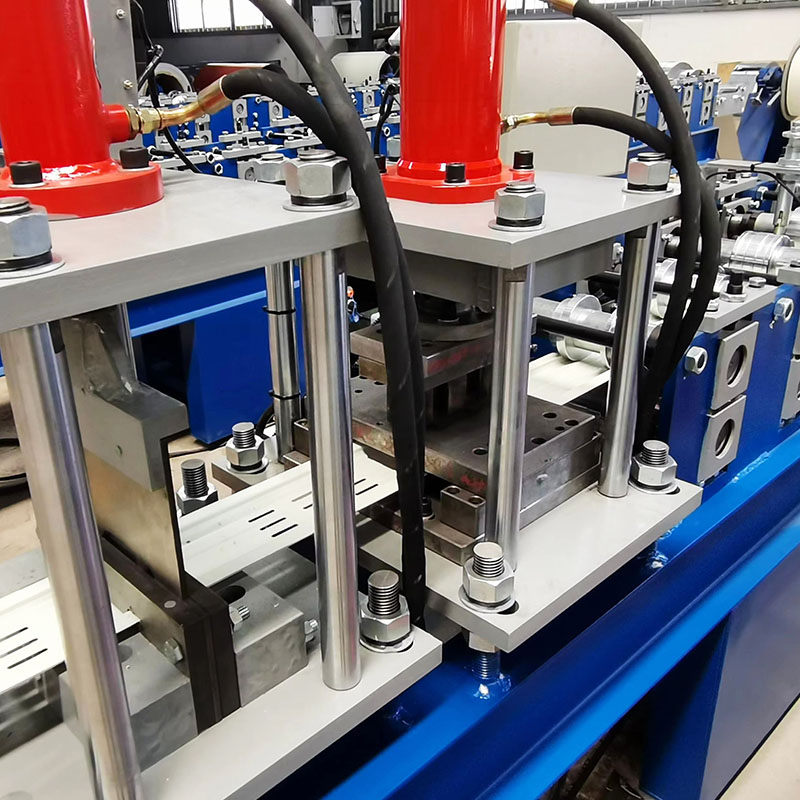

2) Rollers of Machine

Rollers are made of high-quality bearing steel GCr15, CNC lathed, heat-treated, and available with hard chrome coating.

3) Forming cutter

4)PLC Control system (2 type for choosing)

Easy to operate

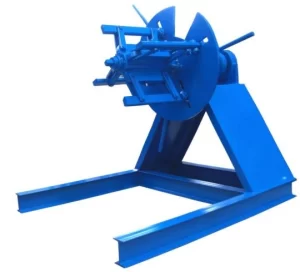

5)Decoiler (2 type for choosing)

- Manual decoiler 2. Hydraulic decoiler

Why Choose SKD Machines?

SKD Machines, a leading Spandrel Roll Forming Machine Manufacturer, are the top choice for clients seeking efficiency, precision, and customization. With extensive industry expertise, SKD offers a wide range of machines that can be tailored to meet specific needs. Known for high accuracy, durability, and fast production, SKD machines are designed to enhance performance and ensure long-term reliability.

A wide variety of alternatives to fulfill various demands.

SKD machines come in a wide range of variants, including high-pressure polyurethane foaming machines and roll forming machines. These machines employ cutting-edge technology and high-grade materials to guarantee that the goods work well and remain consistent in quality. Whether you want efficient and energy-saving foaming solutions or accurate roll-forming procedures, SKD can deliver professional equipment to match your requirements.

Various customization services to satisfy specific demands.

SKD machines not only provide a wide range of conventional goods, but they also accept ODM (original design manufacturing) and OEM (original equipment manufacturing) customization requests. This means you may collaborate directly with our experienced design team based on your individual requirements and preferences to produce bespoke goods that exceed your expectations. SKD may customize the product’s look, function, or performance characteristics to meet your specific needs.

Professional designer team to produce an exceptional design.

Our design team is made up of seasoned and creative individuals that not only have extensive professional knowledge, but also a great understanding of the industry and a solid grip on trends. Whether you choose basic and contemporary or vintage and traditional, SKD’s designers can develop a one-of-a-kind design based on your preferences and requirements.

Deep industry expertise, excellence assured.

SKD Machine has over 15 years of expertise in roll-forming machine production, 20 years of manufacturing experience, and 15 years of overseas trading experience. These invaluable experiences help us to get a thorough understanding of our clients’ demands and expectations, allowing us to give more precise and thoughtful services in product research and development, production and manufacturing, and after-sales support. Our facility is equipped with cutting-edge manufacturing technology and a competent workforce to guarantee that the quality of each product reaches the highest standards.

Own factory, strong witness.

We have our own factory, which means that every step of the process, from raw material acquisition to manufacture and processing, to final product delivery, is subjected to stringent quality control and inspections. At the same time, our factory employs a large number of experienced workers who, through their superior workmanship and extensive expertise, infuse passion and personality into each product.