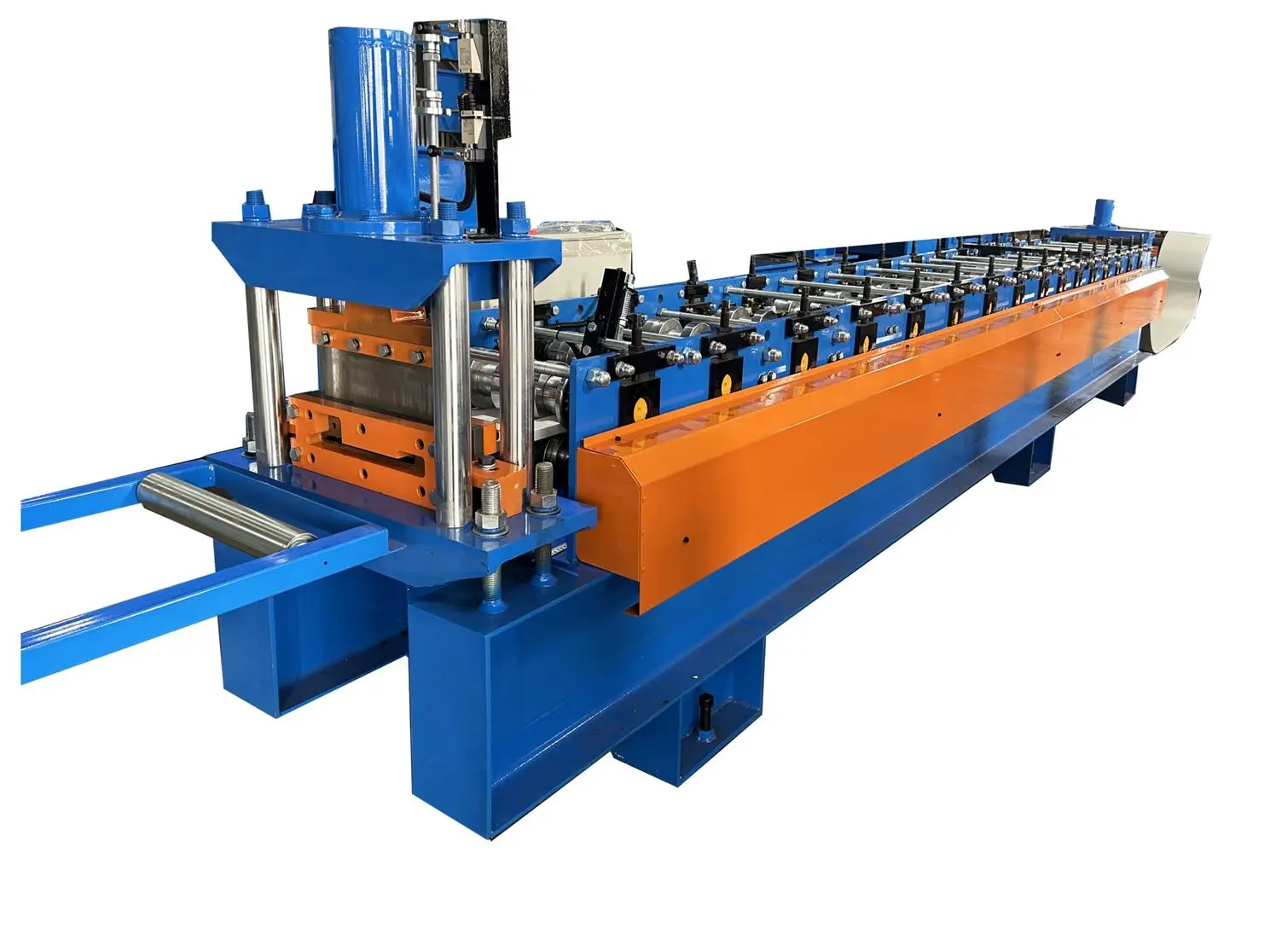

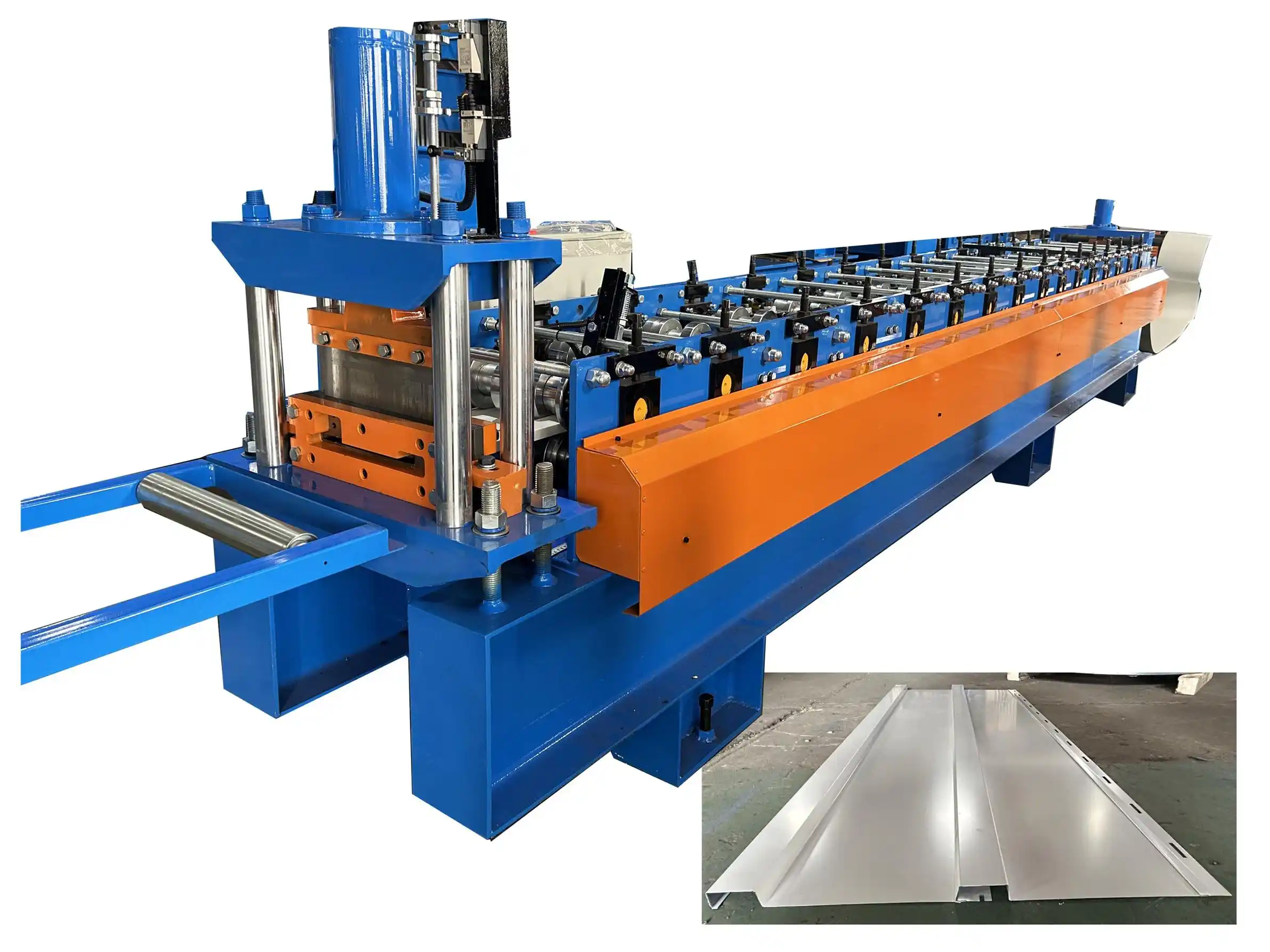

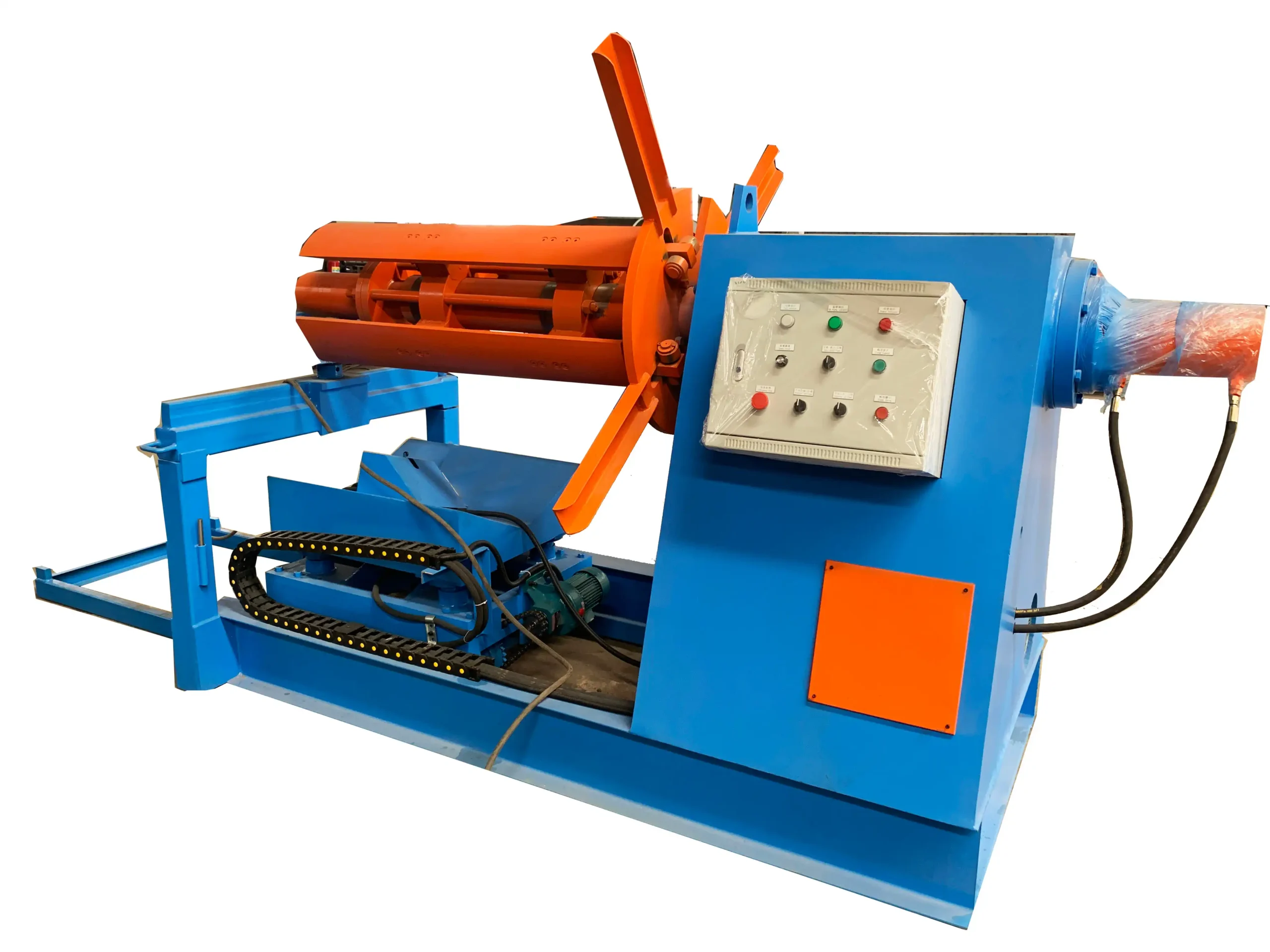

Specialized equipment for producing metal roofing panels, Standing Seam Forming Machine work best when producing panels with self-locking fasteners and hidden or concealed fastening systems.

In order to process metal coils such as pre-painted steel, galvanized or zinc-coated steel, galvanized aluminum, aluminized zinc-coated steel, and aluminum into roof panels with standing seams, standing seam forming machines are highly effective, automated production line equipment. Often, these roof panels use concealed or hidden fastening systems to enhance the roof’s waterproofing and appearance.

Important Elements

- Production efficiency: The vertical seam forming machine can perform high-speed, continuous procedures, which significantly boosts output.

- High precision: To guarantee that the manufactured roof panels have perfect dimensions and a pleasing look, the machine uses precise forming molds and a sophisticated control system.

- Material Diversity: Able to handle a broad variety of distinct metal coil materials to satisfy various client demands.

- Self-locking and Fastener Hiding System: The manufactured roof panels have a self-locking feature that guarantees a solid installation, and the fasteners are designed to be hidden or covered in order to enhance the roof’s appearance and waterproof capabilities.

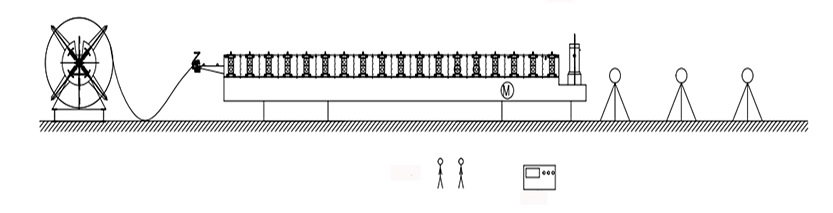

Work Flow and Profile

Profile Decoiler→Manual Pre-Cutter→Feeding Guide Device→Roll Forming System→Hydraulic Post Cutter→Exit Rack

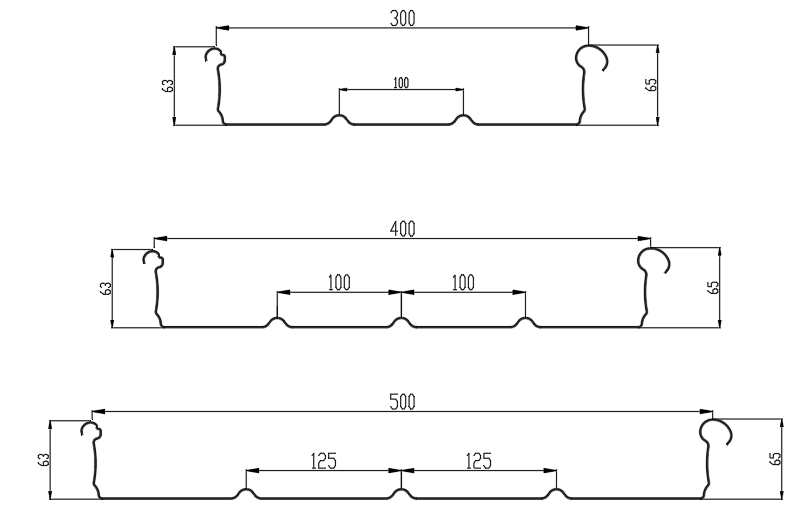

Standing Seam Forming Machine Specifications

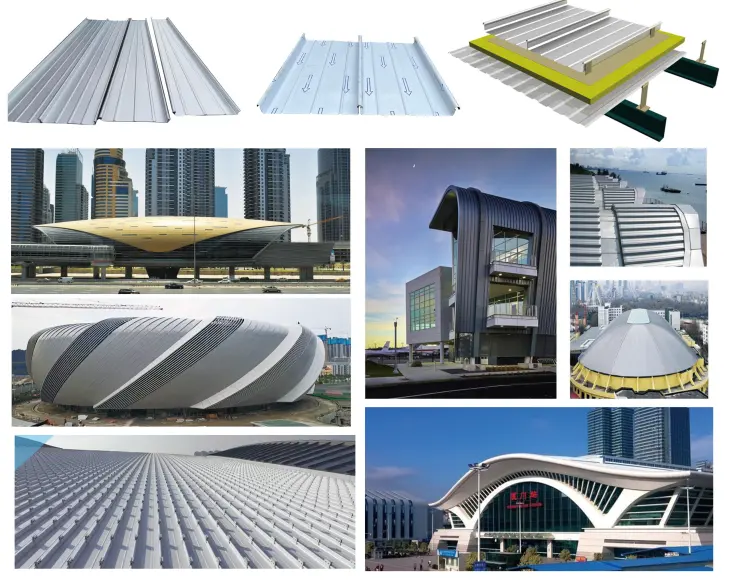

The cutting edge 270° biting technology is used by the standing seam forming machine. Its distinctive shape allows it to accommodate many building styles. As a result, standing seam panels are often used in the building industry, particularly in stadiums and other sizable public entertainment venues, airport terminals, train stations, huge transit hubs, conference and exposition centers, and so forth.

Application

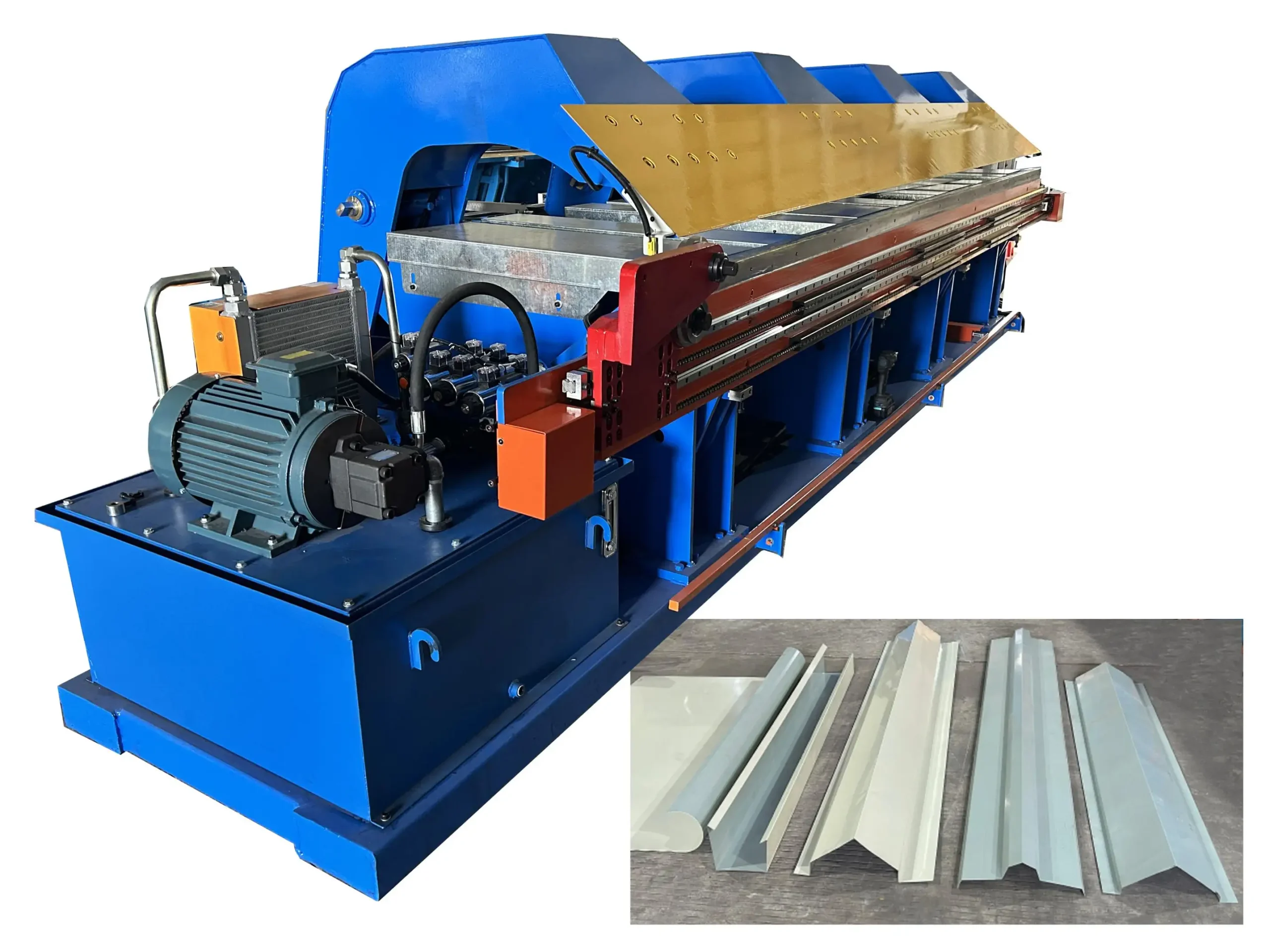

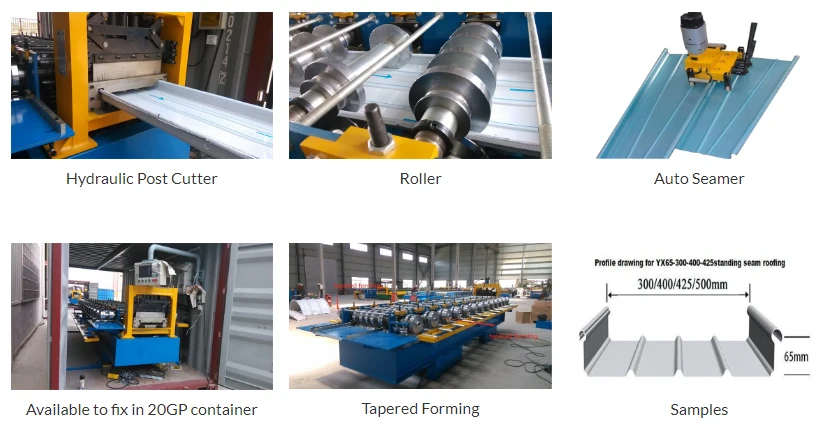

The tapered standing seam machine is a kind of machinery used in the shaping and processing of metal plates, including those made of manganese, magnesium, and aluminum. It is capable of precisely bending metal plates into tapered vertical edges of different widths, which are frequently employed in the construction and decorative industries to create things like building canopies, walls, and roofs.

The tapered standing seam machine can easily handle the processing demands of metal plates of different sizes and shapes since it has more molds and forming tools than the normal standing seam machine. The equipment’s high accuracy, high efficiency, and stability guarantee the quick completion of metal plate forming jobs while enhancing processing quality and production efficiency.

The tapered standing seam machine also requires less maintenance and is simple to use. Its user-friendly interface and humanized control system significantly lessen operational complexity for users and cut labor expenses. Simultaneously, the equipment maintenance is quite convenient. The majority of common issues may be resolved with simple maintenance and troubleshooting, which lowers maintenance costs and downtime.

In conclusion, the tapered standing seam machine is a strong, effective, and accurate piece of machinery for processing metal that is often used in the building, decorating, and other sectors. In addition to increasing processing quality and manufacturing efficiency, it may help users save money on labor and materials. It is a very useful instrument for treating metal.

Application of vertical roll-up plates

Airport terminal

Roofs and walls of airport terminals are often constructed using vertical roll-up plates. Their unique molding process creates a stunning and sturdy structure. This design gives passengers a nice waiting area while also guaranteeing the terminal’s ability to run securely in all weather situations.

Station and large transportation hub

at order to provide passengers a pleasant and secure waiting environment, vertical roll-up plates are often used as platform ceilings, waiting room walls, etc. at stations and major transportation hubs. In addition to improving the space’s openness and brightness, its continuous, smooth curved surface design also improves the transit hub’s overall appearance.

Conference and exhibition center

When building conference and exposition centers, vertical roll-up plates are utilized to decorate the walls and roofs of exhibition halls, conference rooms, and other places to provide a polished, contemporary look. Its superior fire and moisture resistance not only satisfies the strict safety and environmental protection standards of the conference and exhibition center, but also offers visitors and exhibitors a top-notch show space.

Sports stadiums

Vertical roll-up panels are often utilized in stands, roofs, and other building components of sports stadiums to provide fans a pleasant viewing experience. Because of its low weight and stability, it can support the vast spans and tall areas required by sports stadiums. Athletes and spectators may also feel comfortable because to its superior heat retention and thermal insulation capabilities.

Large-scale public entertainment facilities

Vertical roll-up panels are often utilized to adorn walls, ceilings, and other areas in the building of expansive public entertainment venues like theaters and movie theaters in order to create a distinctive creative environment. Its outstanding ornamental performance and flexibility satisfy the designer’s desire for spatial aesthetics while also improving the viewing experience for the spectators.