As a leader in column and rail roll forming machines (also known as roof slat roll forming machines), SKD is focused on providing high-performance, high-precision customized roll forming solutions to customers around the world. We know that in the rapidly developing construction, industrial and infrastructure industries, each project has its own unique needs and challenges. Therefore, we are committed to perfectly integrating innovative design, exquisite craftsmanship and customer needs to create a series of high-quality equipment that meets industry standards and exceeds customer expectations.

Customized services to meet diverse needs

We accept customized needs for various types of column and rail roll forming machines, including but not limited to roll forming equipment with different materials (such as cold-rolled steel plates, galvanized plates, color steel plates, etc.), different specifications and sizes, special shapes and functional requirements. Through in-depth communication with customers, our team of professional engineers will conduct detailed demand analysis and design customized solutions that best suit customer project needs to ensure that the equipment is in the best state in terms of production efficiency, forming accuracy, ease of operation and maintenance.

Leading technology, excellent quality

SKD Machinery Manufacturing Plant adopts internationally advanced CNC technology, automatic control systems and precision processing equipment to ensure that each roll forming machine can achieve extremely high production efficiency and processing accuracy. Our products undergo strict quality inspection and testing to ensure stable and reliable performance during long-term use, meeting customers’ pursuit of high-quality products.

Full-range service, customer first

We are well aware that high-quality service is the key to customer satisfaction. Therefore, SKD Machinery Manufacturing Plant not only provides customized equipment solutions, but also provides customers with a full range of services including pre-sales consultation, solution design, installation and commissioning, technical training, and after-sales maintenance. Our service team is on call at any time to ensure that any problems encountered by customers during use can be solved promptly and effectively.

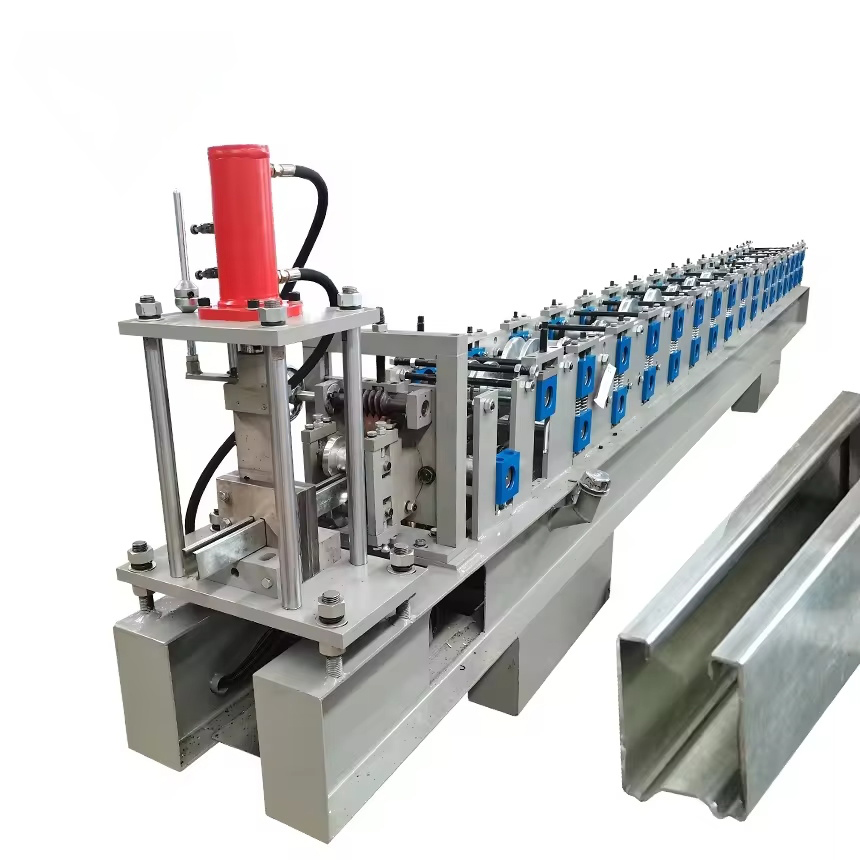

Feature of stud and track roll forming machine

- Stud and Track Roll Forming Machine: If you feed wider material, the machine will build a stud; if you feed less broad material, the machine will make a track; you can also set the machine to punch on the stud or track.

- Stud and track, as well as omega channel, are drywall channels that are used to construct a cost-effective wall and ceiling structure.

- Metal studs and channels are sturdy, lightweight, quick to install, and available in a variety of sizes to suit wall and ceiling applications with many layers of gypsum board.

Flow chart

Advantage of stud and track roll forming machine

- Insulation: The keel ceiling can insulate the top of the room. Its ceiling structure forms an air insulation layer between the room and the ceiling, which can effectively prevent heat from diffusing upward. In the cold winter, it can keep the room warm and save heating costs.

- Sound insulation: The keel ceiling can also effectively insulate, reduce noise, and give people a more comfortable living environment.

- Aesthetics: The keel ceiling can hide the pipes and lines on the ceiling, avoiding direct exposure of the lines and pipes, and at the same time can also increase the shape and aesthetics of the room.

- Space saving: The keel ceiling can increase the height of the room, save living space, and make the room more efficient.

Component of Stud and track roll forming machine know as roofing batten roll forming machine.

1) Feeding

2) Rollers of Machine

Rollers are made of high-quality bearing steel GCr15, CNC lathed, heat-treated, and available with hard chrome coating.

3) Non stop Forming cutter

4)PLC Control system (2 type for choosing)

Easy to operate

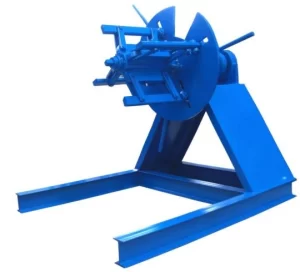

5)Decoiler (2 type for choosing)

- Manual decoiler 2. Hydraulic decoiler

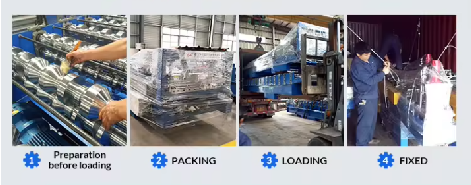

About shipping

Before loading, we made careful preparations to ensure that every link could go smoothly. First, the goods were carefully classified and inspected to ensure that each piece of goods met the transportation standards and was in good condition. Then, we carefully designed the packaging plan according to the characteristics of the goods, using suitable materials such as shock-proof foam, sturdy cartons or wooden boxes, and necessary waterproof and moisture-proof measures to protect the goods in all directions to reduce the risk of damage during transportation.

After completing the packaging, we entered the loading stage. We used professional loading equipment and personnel to place the packaged goods one by one and in an orderly manner on the transport vehicle according to the established loading plan. During the entire loading process, we paid special attention to the balance and stability of the goods to ensure that the goods were evenly distributed and avoid safety hazards caused by the shift of the center of gravity.

Finally, in order to ensure the stability and safety of the goods during transportation, we took a variety of fixing measures. Use ropes, straps or special clamps to firmly fix the goods on the transport vehicle to prevent displacement or falling due to bumps, sudden braking, etc. during driving. Through these careful preparations, meticulous packaging, orderly loading and solid fixing, we lay a solid foundation for the safe transportation of goods.