Z Purlin Machines are a popular mechanical equipment in the building industry. It has the ability to increase production efficiency, reduce production costs, and improve product quality and accuracy, all of which are crucial to the construction sector’s growth.

The Z Purlin Machine can also be customized to fulfill the manufacturing needs of different specifications and sizes. At the same time, it can be coupled with other construction machinery to form a complete production line, resulting in automated and continuous manufacture.

Specification

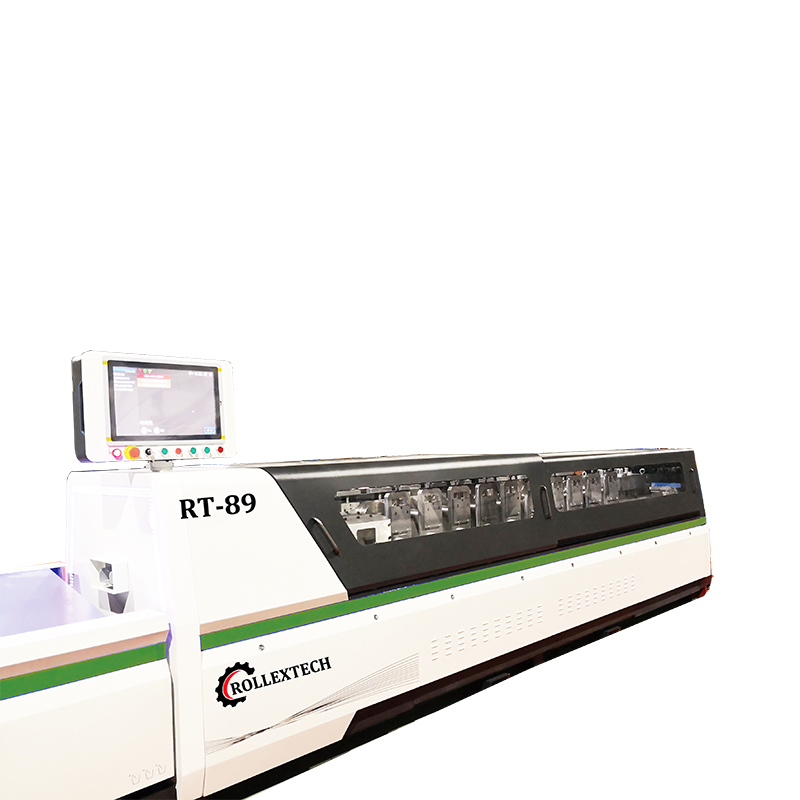

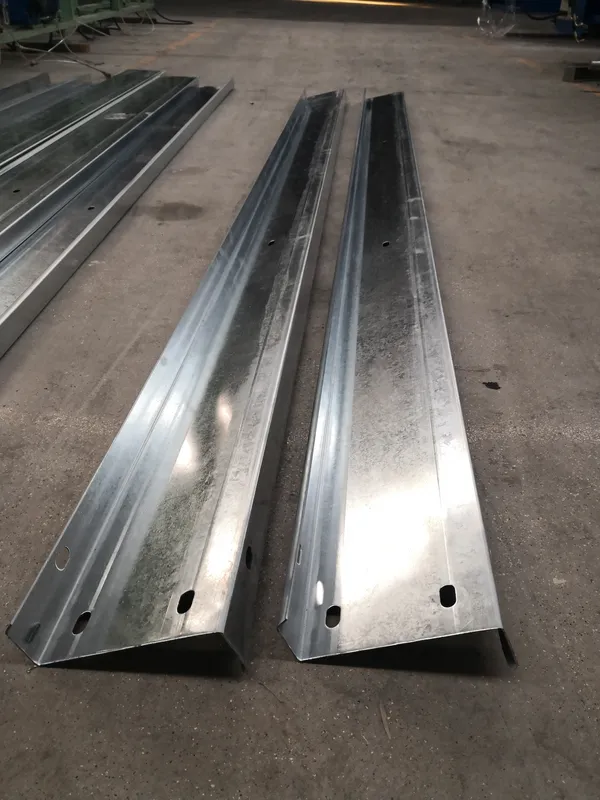

The Z120-300 purlin machine consists of a decoiler, feeding and leveling device, punching system, pre-shear, conveyor system, roll forming system, hydraulic post cutting, run out table, hydraulic station, and PLC control system. Its distinctive quick-change feature: Assemble with a liner guide to allow the machine to change web easily and smoothly. Produce standard products with yield strength of up to 235Mpa, a long production line, and no open mouth on final products, resulting in increased production efficiency and suitability for current manufacturing. This machine is simple to use and works with excellent precision.

Main features

The following are some benefits of the CZ purlin machine’s automatic size-change type:

- Generate distinct purlin sizes (Z120-300) without requiring adjustments to rollers or spacers.

- There is no need to switch cutters for different sizes.

- Simple operation and low maintenance

- Infinite sizing (any size within the range of the machine), which conserves material

- 0ptional Punch holes on the flange side and purlin web side at any point.

1.Z purlin machine feeding and leveling

It is used to flatten the material before feeding it into a roll forming machine.

2.Pre-punching device

Punch on a flat sheet. PLC controls punch quantity and horizontal position; vertical position is adjusted manually.

Punching quantity& size: as per customer’s requirement

3.Pre-cutting device

It was used to trim raw materials before rolling them.

4.All purpose forming cutter

5.Z Purlin Main Machine

Z-steel equipment has a unique range of applications.

- Z-steel has become an integral supporting structure for steel structure workshops and warehouses due to its high strength, outstanding bearing capacity, and corrosion resistance, and is extensively utilized in critical sections such as main beams, secondary beams, and roofing.

- Z-steel guardrails, with their high strength, superior impact resistance, and corrosion resistance, are an essential component of highway safety equipment.

- Furthermore, Z-steel is extensively utilized in the support and load-bearing components of big stadiums and bridges, and its consistent performance and dependable quality have gained widespread acclaim.

- In terms of agricultural facilities, Z-steel, as the chosen material for greenhouse skeleton structures, not only offers strong support and bearing capacity but also optimizes greenhouse ventilation and lighting effects, resulting in a more conducive climate for agricultural output.

- At the same time, Z-steel is widely utilized in the manufacture of agricultural machinery, which increases its strength and stability and offers more dependable equipment support for agricultural productivity.

- Z-shaped steel is often used in the automotive industry for body structures and chassis. Its robust structure and stiffness give the required stability and safety for vehicles, making it a crucial and significant material in the automotive industry.

- The shipbuilding sector is inextricably linked to Z-shaped steel. Z-shaped steel is often utilized in hull constructions and ship equipment. Its great strength and corrosion resistance allow it to endure the severe maritime environment while also ensuring ship safety.

- Z-shaped steel is often used in railway engineering for track supports and bridge constructions. Its superior strength and stiffness ensure the stability and safety of railroads.

- In mining engineering, Z-shaped steel is used to produce mining equipment and supports. Its superior strength and corrosion resistance allow it to withstand the diverse strains of the mining environment as well as the high pressure of ore.

- In addition, Z-shaped steel is extensively employed in the solar energy industry. It is often used to create solar supports and support structures. Its weather resilience and stability may fulfill solar panel installation requirements while also providing a solid infrastructure for solar power production.